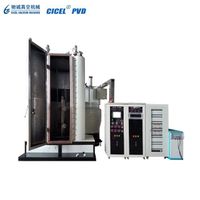

Electronic products multi-arc magnetron sputtering PVD vacuum coating machine

-

Supplier: KING TECH TRANSMISSION CORPORATION -

Region: Taiwan, China -

Contact: Mr. KING TECH KT -

Price: $100000.00 /unit -

Min. Order: 1 unit

Product details

| Brand Name: | KING TECH; | Technology: | multi-arc ion magnetron sputtering; |

| Vacuum System: | Molecular Pump, Roots Pump, Rotary Vane Pump; | Packaging Detail: | wooden package 4 units 1. chamber 2. water tank 3. electric control cabinet 4. pump system; |

| Type: | decorative coating machine; | Condition: | New; |

| After-sales Service Provided: | Field maintenance and repair service,Video technical support,Online support; | Port: | Dalian, China or Keelung, Taiwan; |

| Dimension(L*W*H): | L3600*W3500*H2500MM; | Power(W): | 70K; |

| Coating: | Vacuum Coating; | Advantage: | compact structure, stable performance, simple operation; |

| Supply Ability: | 20 Unit/Units per Month; | Voltage: | 380V; |

| Place of Origin: | China; | Payment Terms: | L/C,T/T; |

| Substrate: | metal, stainless steel; | Color: | gold, brown, chromium white, silver gray, ultra black, etc.; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Weight: | about 5 Ton; |

| Warranty: | one year; |

Product Overview

ZY-1313 decorative PVD coating machine is our self-developed multi-arc ion magnetron sputtering coating machine which has various advantages of both ion plating and magnetron sputtering. The combination of two technologies greatly improves the film uniformity and adhesion, and then expands the scope of application. ZY-1313 is equipped with latest PLC intelligent program and touch screen automatic control system to ensure simple operation and stable performance. With energy saving design, it is the ideal choice for decorative coating.

Introduction

After years of research and technological innovation, ZY-1313 multi-arc ion magnetron sputtering coating machine integrates planar cathode arc ion plating technology, DC magnetron sputtering technology, mid-frequency magnetron sputtering technology and pulsed bias technology, and uses high power mid-frequency sputtering power supply as well as mid-frequency magnetron cylindrical targets to greatly improve the utilization ratio and sputtering rate of targets. ZY-1313 is an advanced decorative PVD coating machine with good configuration, high efficiency and stable performance.

Adopting high quality stainless steel body and hidden cooling water system, ZY-1313 multi-arc ion magnetron sputtering coating machine concerns both quality and appearance. As the latest developed pulse bias power system ensures excellent film adhesion and smooth finish, it is good at depositing high quality film in various colors such as IP black, rose gold, IP gold, sapphire blue, champagne, silver, coffee, gun black, zirconium gold, rose red, etc. And the coating layer is extremely dense and uniform with strong adhesion. The machine is widely used in digital products, watches and clocks( watchband, dial etc.) jewelry, luggage accessories, glasses frames, lamps and lanterns, golf clubs, mobile phone shell, tableware, stainless steel hardware (sanitary ware, door handle, door lock) and other fields of the decorative coating.

Adopting high quality stainless steel body and hidden cooling water system, ZY-1313 multi-arc ion magnetron sputtering coating machine concerns both quality and appearance. As the latest developed pulse bias power system ensures excellent film adhesion and smooth finish, it is good at depositing high quality film in various colors such as IP black, rose gold, IP gold, sapphire blue, champagne, silver, coffee, gun black, zirconium gold, rose red, etc. And the coating layer is extremely dense and uniform with strong adhesion. The machine is widely used in digital products, watches and clocks( watchband, dial etc.) jewelry, luggage accessories, glasses frames, lamps and lanterns, golf clubs, mobile phone shell, tableware, stainless steel hardware (sanitary ware, door handle, door lock) and other fields of the decorative coating.

Features

Large size furnace design ensures large output and high efficiency, and helps save the cost.

Compact structure, stable performance, simple operation and wide range of applications.

With good repeatability and controllability of film thickness, the coating layer is smooth, dense and lustrous.

Characters of Decorative Coatings

IP series

DH series

Packing & Delivery

Related Products

Electronic Products Magnetron Multi-Arc Vacuum Coating Machine

91.8% Response Rate

multi-arc ion coating machine

91.8% Response Rate

Cutting Tools Multi-arc Ion Vacuum Coating Machine

91.8% Response Rate

VIEW MORE

You may like

-

Powder Coating Industrial Oven Powder Coating Oven

-

Vacuum coating machine

-

Industrial grade chrome plating machine booth spray paint chrome plating machine

-

Gema Optiflex 2 Vibrating Box Feed Metal Electrostatic Powder Coating Machine Vibrating Powder Coating Machine

-

Stainless steel 10L spray chrome coating machine paint coating nano chrome plating machine

-

Hot Sale Classic Portable Manual Electrostatic Powder Coating Machine (WX-101)

-

High quality automotive hub sputtering vacuum coating machine

-

CE approved industrial powder coating curing oven gas electric stand for sale in China

-

Secondary Vacuum Coating Machine/Vacuum Coating Machine

-

Promote products Mirror spray chrome plating Fine surface spray chrome plating equipment

Other Products

-

$100000.00 / unit

$100000.00 / unit

Related Search

pvd vacuum coating machine

metal tools pvd vacuum coating machine

multi functional magnetron sputter

pvd system coating machine for cutting tools

manufacturers vacuum coating machine suppliers

glass vacuum coating machine

offer vacuum coating machin suppliers

used vacuum coating machine

electron product electron power meter

electronics products call phone