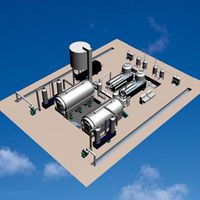

RESEM 15 Tpd Convert Waste to Energy Scrap Plastic Pyrolysis Equipment

-

Supplier: Shangqiu Ruixin General Equipment Manufacturing Co., Ltd. -

Region: Henan, China -

Contact: Ms. luisa zhang -

Price: $58000.00 /set -

Min. Order: 1 set

| Size of reactor: | D2800mm L7700mm; | Package Type: | -; |

| Equipment Capacity: | -; | Brand Name: | RESEN; |

| Selling Units: | Single item; | Heating material: | Coal, charcoal, fuel gas, fuel oil; |

| Thickness of reactor: | 14mm&16mm; | CARBON BLACK: | 30% to 35%; |

| Raw material: | Waste tires, scrap plastic, waste rubber; | Place of Origin: | Hainan China (Mainland); |

| Condition: | New; | Single package size: | 1750X260X260 cm; |

| FUEL OIL: | 45-50%; | Power in total: | 22-30Kw; |

| Rotate speed of reactor: | 0.4--0.8 turn/minute; | Delivery Detail: | 30 days after payment; |

| Material of reactor: | Q245R/Q345R boiler plate; | Model Number: | -; |

| Single gross weight: | 35,000 KG; | Operating pressure: | Constant pressure; |

| After-sales Service Provided: | Engineers available to service machinery overseas; |

Waste plastic to oil pyrolysis plant design

1. Put pre- processed plastic into the reactor by full-automatic feeding machine, after they are delivered into stock bin by conveyor belt. Total quantity shall be controlled under 2/3 of reactor for rotating more smoothly. Then close the feeding door and open the heating system.

2. From 100 ℃ to 250 ℃ is the preliminary stage , and the oil gas shall be released at 200 ℃ . From 280 ℃ to 350 ℃ is the top output rate interval.

Oil gas will be collected into manifold, and the heavy particles and oil will be gathered and liquefied in center of manifold and drop down into the heavy pyrolysis oil tank.

The lighter gas will rise up to the multi-functional oil condensers, then be liquefied into oil and stored in the oil tank.

The incondensable gas through desulfuration and de-dusting by hydroseal will be led to the furnace for heating.

3. Cool down the reactor after the pyrolysis process.

The carbon black will be discharged when the temperature reaches between 50 degrees and 70 degrees. The end products you can get from the waste tyre to oil process are tyre pyrolysis oil, carbon black, steel wire and combustible gas.

Working process:

Pyrolysis machine specification

Items | Contents | ||||

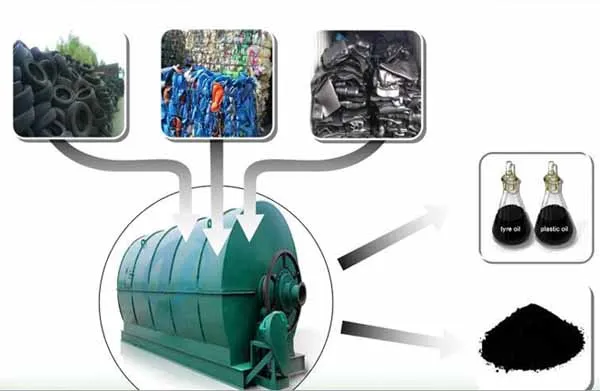

Raw material | Waste tires, scrap plastic, waste rubber | ||||

Structure form | Horizontal | ||||

Model | HA-5-PT | HA-8-PT | HA-10-PT | HA-15-PT | HA-20-PT |

Size of reactor | D2000mm | D2200mm | D2600mm | D2800mm | D2600mm |

L4500mm | L6600mm | L6600mm | L7700mm | L6600mm | |

24-hour capacity | 5 tons | 8 tons | 10 tons | 12 tons | 20 tones |

Operating pressure | Constant pressure | ||||

Heating material | Coal, charcoal, fuel gas, fuel oil | ||||

FUEL OIL | 45-50% | ||||

CARBON BLACK | 30% t0 35% | ||||

STEEL WIRE | 10% to 15% | ||||

GAS | 10% to 12% | ||||

Material of reactor | Q245R/Q345R boiler plate | ||||

Thickness of reactor | 14mm&16mm | ||||

Rotate speed of reactor | 0.4--0.8turn/minute | ||||

Mode of cooling | Water cooling | ||||

Power in total | 22-30Kw | ||||

Life | 5 years | ||||

Given below wastes that you can recycle:

1. Waste Plastic

2. Rubber

3. Plastic or rubber parts from vehicles

4. House garbage, Plastic cable, Plastic bag, Sole

5. Mixed plastic (HDPE, LDPE, PE, PP, Nylon, PS, ABS etc.)

6. Leftovers of paper, Submarine cable

7. Mixed waste plastic from waste paper mill

8. Multi Layered Plastic

9. Waste engine oils etc.

Pyrolysis machine final production

Oil report

| items | diesel(afterdistillation) | Mixed oil,pyrolysis oil | GB 0# diesel |

| Oxidation stability | 2.0 | 1.5 | 2.5 |

| volume % | 0.005 | 0.005 | 0.05 |

| steam residual carbon residue % | 0.25 | 0.25 | 0.3 |

| ashes% | 0.008 | 0.1 | 0.01 |

| copper corrosion/level | 1.1 | 1.1 | 1 |

| water % | traces | 1 | traces |

| mechanical impurities | no | no | no |

| density | 0.85 | 0.88 | 0.83-0.87 |

| Freezing point /℃ | -10 | -5 | 0 |

| Flash point(closed)/℃ | 45 | 40 | 55 |

| Kinematic viscosity | 2.5 | 5.0 | 3.0-8.0 |

| combustion value | 9500 | 10000 | 8500 |

| color | 1.2 | 4.5 | ≤3.5 |

| Cetane number | 43 | 38 | 46 |

- 1. Professional service team to provide technical support for pre-sale, sale and after-sale.

- 2. We will provide installation instructions on your working site, test machines and provide training for your workers.

- 3. 12 months quality warranty for main machine.

- 4. 24 hours feedback response: solve your problems online or on your working site.

- 5. Accessories and spare parts are available at cost price all year round.

Shangqiu Ruixin Genaral Equipment manufacturing Co., Ltd is a high-tech enterprises integrating scientific research, production, sales, service, import and export.

Since our company was founded in 2009, the company has gained successfully 3 patents and more than 24 utility model patents; completed the "ISO9001 international quality system certification", "ISO14001 Environmental Management System Certification Cert ","CE certification". Our company was named municipal enterprise technical centers, The top ten most innovative technology-based business model of Henan Province, " Henan Province, energy saving technology innovation demonstration enterprise certificate "," Shangqiu Environmental Protection Special Equipment Manufacturing Industry Association unit "and other honorary titles.

-

Newly designed waste oil-to-diesel refinery

-

Fully Automatic Plastic Recycling Pyrolysis Diesel Tire Fuel Plant

-

Beston Group does not need to install a small pyrolysis machine for batch pyrolysis of 1-3T/D plastic tire oil sludge

-

Waste Tire Pyrolysis Diesel Plant Machine Manufacturer 5 Ton

-

Automatic control machine for biomass waste plastic tire pyrolysis machine

-

profitable small pyrolysis machine mini pryolysis plant

-

Small batch waste tire/plastic/MSW pyrolysis plant to convert solid waste into fuel oil pyrolysis machine 1-2 tons

-

New Design to Recycle Scrap Tires into Diesel with 50ppm Sulfur

-

Small integrated scrap aluminum and plastic pyrolysis plant provides fuel for machines

-

CE certified 15-50 tons automatic plastic pyrolysis plant continuous waste tire pyrolysis system

Other Products

-

$60000.00 / set

$60000.00 / set