BG-150E High Effciency Automatic Fully-closed Candy/Sugar/Chocolate bean/Nuts/Tablet Syrup Spray Film Coating Pan Equipment

-

Supplier: Zhejiang Jiangnan Pharmaceutical Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Lena Ruan -

Price: $36000.00 /set -

Min. Order: 1 set

| Application: | Pharmaceutical; | Packaging Detail: | Export-standard and sea-worthy wooden case; |

| Place of Origin: | Zhejiang China; | Condition: | New; |

| Usage: | Pharmaceutical; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Weight: | 2000kg; | Port: | Shanghai/Ningbo Port; |

| Others: | High Finished Product Rate; | Power(W): | 40kw; |

| Certificate: | CE,ISO9001, GMP; | Life: | LongLife service; |

| Function: | High Effieciency and Good Shape Pill; | Usage: | Can quantificationally pack tablets, capsules, pills, sugar and so on.; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Quality: | High quality; |

| Supply Ability: | 100 Unit/Units per Year; | Warranty: | 1 Year; |

| Voltage: | 380V; | Advantage: | Various Patent Technology; |

| Brand Name: | Jiangnan; | Dimension(L*W*H): | 1570*1260*2250mm; |

| After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; | Main Market: | Overseas Markets; |

| Certification: | CE GMP ISO9001; |

Performance and Characteristics:

- The coating boiler equipped in the high pressure spray gun, there set a cleaning sprayer at the air exhaust exit and hot air mouth, which can be rotated in automatic and full direction ,without dead corner more convenient to clean. (Option)

- Select the imported spray gun. It's convenient to operate and easy to master and flexible controlled technological requirement. The spray gun head requirement must keep in the range of 0.29 Mpa to 0.39 Mpa. Angle and sector can be adjustable , uniform density and particle in spray pressure and 0.4-0.5Mpa in atomization pressure that avoid the dropping leakage and blockage phenomenon of size, uniform atomization and large spray area, practical to adjust flow, free leakage and blockage, angle and sector.

- Film coating machine contains the mechanical device of cauldron wrapping little material can coat at least 20~40kg plain pills in 150 type coating machine, regulate through it inherent machinery, make a small mount of medium coat in cauldron and will not cause the wasted of dressing and greatly improve the scope of appliance.

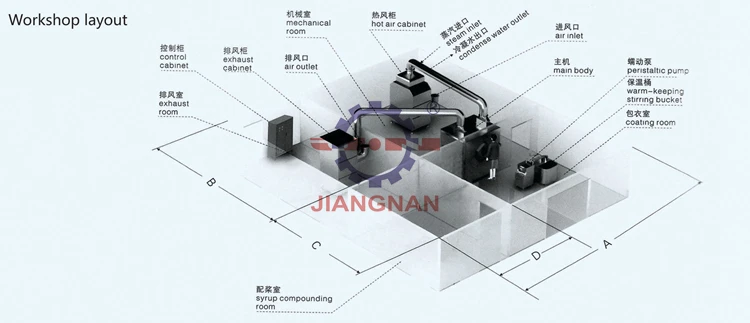

Filtration Hot Air Cabinet

Firstly, air inhaled in through the centrifugal fan should be purified up to the 100,000 Level after three times filtration, involving primary filtration, medium filtration and high filtration, then be blown to the drum of main machine through the (steam or electrothermal) .Equipped with a vibration damper. Equipped with primary filtration device in the air inlet.

Air Exhaust Cabinet

Used for exhausting air out of drum in the major machine ( including dust absorption), keeping the working area under negative pressure. Equipped with a vibration damper. The exhaust outlet is equipped with a reflux-proof device. Close the exhaust cutlet before stop the machine to prevent the air in the exhaust cabinet from reflux. It is equipped with dust abatemert & filtration by vibration. so the vibration and dust are insulated, the dust is stopped from fly off and the dust abatement is automatically separated, which makes easy.

Agitating and Holding Tank (Electric-Heating)

Thermal stirring drum adopts electric heating type. It is equipped with pneumatic stirrer which is driven by compressed air, stable rotating speed and stepless speed regulating, medium can be stirred homogeneous. It can be controlled automatically at normal temperature to 80°C, easy-operating, safe and reliable. All parts are made of stainless steel, inside and outside is mirror polished.

Basic Working Principle:

The tablets in drum make complicated and constant track movement with easy and smooth turn frequent exchanging in a clean and closed drum of the film coating machine. The coating mixed round in the mixing drum are sprayed on tablets through the spray gun at the Inlet un action of the peristaltic pump. Meanwhile under the action of air exhaust and negative pressure 100,000 clean hot air supplied by the air exhaust cabinet is exhausted from the fan at the sieve meshes through tablets. So these coating mediums on the surface of tablets get dry forming a coat of firm, fine and smooth film. The whole process is finished under the control of PLC.

Q: Are you really a manufacturer? Where is your factory? How can I visit your factory?

A: Sure, we are a source manufacturer, Zhejiang Jiangnan Pharmaceutical Machinery Co.,Ltd. SINCE 1997. Our factory is located In Rui'an city, Zhejiang province. We warmly welcome you to visit our factory if you have a travel plan.

Q: How can I know if your machine is designed for my product?

A: Don't worry, you can send us your rough draft or product design. We will confirm with engineers and designers. After the machines are done, we will take videos and clearer pictures for you. We can also show you on-line by video chatting. And the machines will be adjusted well before shipment.

Q: How can I trust you for the first-time business?

A: Please note our business license and certificates above. If you don't trust us, we suggest using Alibaba Trade Assurance Service for all transactions to protect your money and ensure our service for you.

Q: How about the after service and guarantee period?

A: We offer 12 months warranty since the arrival of the machine. Overseas technical support is available. We have professional team with experienced technician to serve abroad and do the best after service to assure the machine whole life usage.

Q: How to contact you?

A: You can click at the "contact supplier" to contact online persons. We are always here for you.

Need more machines details and videos? Please contact us directly!

-

BYC-600 sugar coating machine is used for sugar coating of tablets and pills in the food industry

-

Nut/Chocolate/Almond Peanut Candy Coating Pan Machine Nut Icing Machine

-

Hot Sale Stainless Steel Small Pill Candy Sugar Diaphragm Coating Machine

-

BYC 800 sugar coating machine, tablet and pill coating machine, sugar coating machine

-

Commercial Fondant Sugar Coating Machine Almond Nut Peanut Solution Coating Machine

-

Hot Sale All Stainless Steel Tablet Film Coating Equipment Sugar Coating Machine

-

Laboratory Tablet Coating Machine Pharmaceutical Equipment

-

Food Small Automatic Nut Candy Candy Chocolate Peanut Almond Candy Tablets Nano Film Coating Pot Machine Coating Machine

-

Polishing machine Peanut tablet coating machine

-

Small candy nut icing pan machine