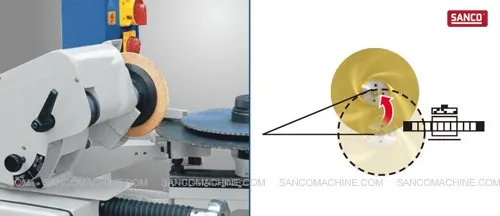

Circular Saw Blade Sharpener Machine

-

Supplier: Zhangjiagang Sanco Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Asky Sanco -

Price: $1000.00 /set -

Min. Order: 1 set

| Color: | Blue or customized; | Port: | Shanghai, Ningbo; |

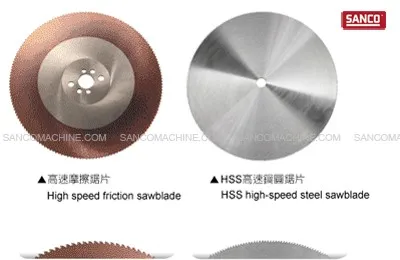

| Industry Application: | grind or make teeth on saw blade; | spare parts: | grind wheel, index plate; |

| Voltage: | 220V/380V; | Max. Grinding Diameter: | 450; |

| CNC or Not: | Normal; | Delivery Detail: | Shipped in 3 days after payment; |

| Payment Terms: | L/C,T/T,Western Union; | Function: | Sharpening; |

| Max. Grinding Length: | 1500mm; | After-sales Service Provided: | Engineers available to service machinery overseas; |

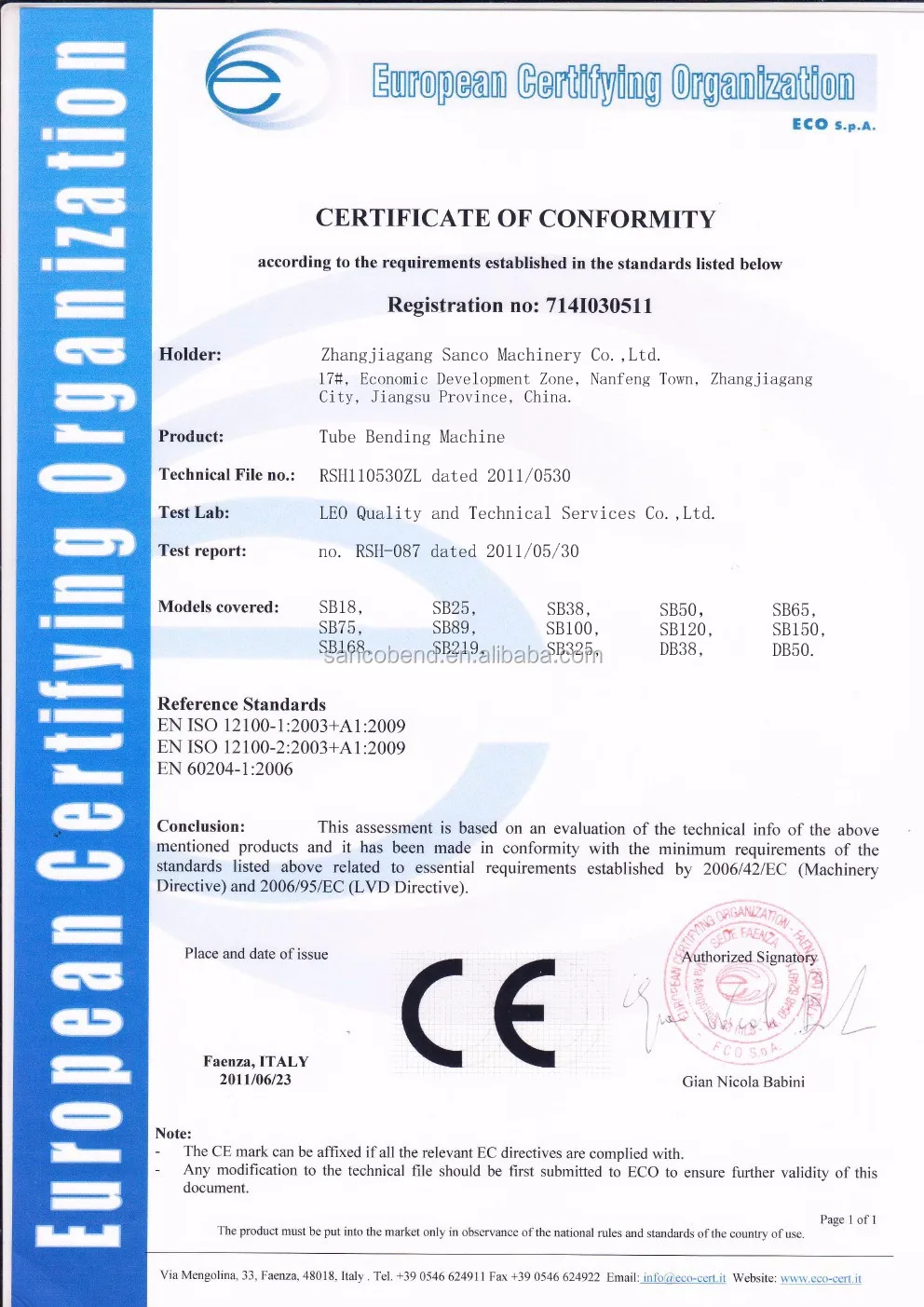

| Dimension(L*W*H): | 700*700*1400; | Certification: | CE; |

| Place of Origin: | Jiangsu China; | Process Saw Blade: | M42, W5, M4B, M2; |

| Material: | HSS saw blade; | Type: | Universal; |

| Gurantee: | 12 months; | Brand Name: | Sanco; |

| Supply Ability: | 30 Set/Sets per Week; | Weight: | 250kgs; |

| Condition: | New; | Packaging Detail: | wrapping film----plastic cover----Wooden case 15 machines in one 20"GP (still has space for other small machines or product customer bought in China.); |

| Controlling Mode: | ELECTRONIC CONTROL; | Model Number: | S-450; |

| Power(W): | 2.2KW; |

S-450 Saw Blade Sharpening Machine, with quality construction, precision sharpening is simple and easy. Setup can be completed in just minutes. The elimination of time-consuming adjustment reduces labor costs. You can do your own sharpening economically and quickly right in your own shop, the way you prefer. It increases efficiency, as sawblades can be sharpened to exact specifications without delay.

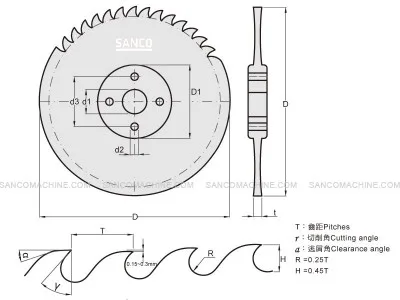

Capacity Φ50 - 450 mm

Pitch Range Max 25 mm

Depth of Teeth Max 8 mm

Range of Cutting Angle 0° - 30°

Feed Speed 45 - 180 teeth / min

Max. Thickness of Blade Max 8 mm

Grinding Wheel Diameter Φ70 - 150 mm

Grinding Wheel Speed 4500 round / min

Drive Motor 1/2 HP

Grinding Wheel Motor 3/4 HP

Machine size 1330x800x800 mm

Machine weight 160 kgs

CE, ISO90001 marked

All cast components, except for those made of aluminum, are made from ductile iron.

Simplified design, easy operation, and precision built for years of accurate sharpening work.

Main Features

1) All cast components, except for those made of aluminum, are made from ductile iron.

2)Simplified design, easy operation, and precision built for years of accurate sharpening work.3)Alternative high/low teeth can be sharpened in only one pass.

4)The tooth height difference is varied and shown on the indicator, for perfect sawblade sharpening.

5) Quick set cutting angle saves valuable set-up time so that sharpening is done quickly.

6)Blade thickness is quickly adjusted and can be read on indicator meter.

7)Tooth chamfering is easily performed, without need to replace grinding wheel.

8)Economical, efficient and simple construction. Drive assembly is a simple combination of driving

9)motor and cam drive motor, providing dependable feeding and trouble-fee operation.

10)Micrometric adjustment for pitch and depth of teeth.

11)Variable speed pulley affords a complete range of feed from 45 to 180 teeth per minute.

12)Convenient hand lever changes tooth profile quickly.

13)Positioner pawl is tungsten carbide tipped for longer wear, and offers accurate feeding.

COMPANY

SANCO (Taiwan and China mainland)Machinery Co., Ltd. was established in 1984, and have cooperation with Taiwan bender company since 1989, specialized in manufacturing Pipe Bending Machine, Metal Circular Saw Machine, Pipe End Forming Machine, Polishing Machine, Chamfering Machine and so on. In 1984, SANCO and "Shanghai Aircraft Design and Research Institute" joint the production of hydraulic pipe bending machine. And in 1984, "Shanghai Aircraft Manufacturing Co., Ltd." assembled 25 airplanes of American model MD82. Chinese government required SANCO mapping the prototype of Italian bending machine, and SANCO manufacturing the bending machine to produce airplane related accessories.

With 96 workers, 20 professional and technical engineers. SANCO company occupies 20,000 square meters, construction area of 15,000 square meters.

The three-dimensional CNC bending machine developed by SANCO is advanced than other Chinese factories. SANCO is the leader of drafting the "Chinese Standard of CNC Pipe Bending Machine" (GB / T28763-2012), released in November 2012, and implemented in May 2013. And SANCO is also the leader of "Chinese Standard of Pipe Bending Machine Safety" (GB28760-2012), released in November 2012, and implemented in October 2013.

All machines marked IS9001: 2000 and CE. SANCO machines exported to the United States, UK, France, Russia, Australia, India, Brazil, Poland, Canada, South Africa, Mexico, UAE, Saudi Arabia, and so on 58 countries.

NOW, AND FOREVER MORE ... SANCO DO THE BEST OR NOTHING.

Pre-Sales Service

* Inquiry and drawing consulting support.

* Sample testing support (if need)

* Visit our Factory.

Customer inspect on site

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

www.sancomachine.com to know more us.

Finishing workshop 2

5 sets CNC Centers

Finishing workshop 2

CNC Punching Machine

Machine Body welded

In Stock to ensure short delivery time

Hydraulic bending machine

Roll bending machine

Double head bending machine

SANCO MACHINERY CO., LTD Since 1984

Add: 17#, Economic Development Zone, Nanfeng Town, Zhangjiagang City, China.

Tel / Fax: +86-0512-58900248

Cell phone / WhatsApp: +86-158-9547-5880

Skype: asky-sanco

www.sancomachine.com

-

High quality face tooth grinding tct table saw blade grinder sharpener circular saw blade machine

-

Band Saw Blade Sharpener

-

Grinding roller ball plastic cartoon ball cosmetic roller ball polishing and grinding machine

-

Woodworking Planer Blade Sharpener Planer Blade Sharpener

-

Crankshaft grinder MQ8260Bx1600

-

Woodworking combination woodworking belt sander hot sale

-

Portable tungsten electrode grinder is suitable for 1.0mm-3.2mm tungsten electrode

-

WS1000H 10" WET SHARPENER industrial quality blade sharpener popular in the US market

-

Two-way water-cooled low-speed electric wet stone sharpener

-

Rectificadora De Valvulas Different Styles Engine Valve Grinder With Buttons

Other Products

-

$5000.00 / set

$5000.00 / set -

$6000.00 / set

$6000.00 / set