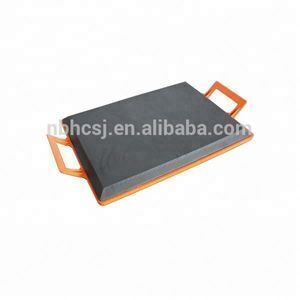

Cushioned Kneeling Board kneeler ,knee safety board,soft EVA for garden

-

Supplier: Ningbo Huachang Plastic Product Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Billy He -

Price: $3.00 / >=1000 units -

Min. Order: 1000 units

| Port: | Ningbo; | Place of Origin: | Zhejiang China; |

| Brand Name: | HC; | Model Number: | HC-P-P2013465; |

| Supply Ability: | 5000 Piece/Pieces per Month; | Packaging Detail: | According to requirement of customer .; |

| Payment Terms: | L/C,T/T; | Product Name: | garden kneeler; |

Cushioned Kneeling Board kneeler /knee board /safety board /soft EVA

size : (61+49)*35*4.5 CMm

material : PP, EVA a

weight : 1050g

Specifications:

Material: NAK80, S136, P20 SO ON, ABS PE PC PVC

Standard: HASCO,STACK,DME,PCS..

delivery time :30days

ISO9001:2000 OEM&ODM

Why choose us?:

1. More than 30-years experience.

2. ISO9001:2000 certificated.

3. Competitive price with high quality.

4. More than 50 machines support to run the business.

5. Custom R&D program coordination.

6. Expert technicians.

8. Diligent and loyal workforce.

9. Up-to-date software.

10. International standards, SAY, HASCO, DME, MISUMI, etc

11. Well-rounded after service.

Important Note:

1. The injection mould is customized for our clients.

2. We do not sell ready-made injection mould, but custom injection mould. So, no price list available.

3. Quotation available after discussion on requirements and design.

What’s our Injection Mould experiences?:

1. Multiple cavities Injection Mould

2. Insert Injection Mould

3. Multiple slider action Injection Mould

4. Sandwich Injection Mould

5. Hot runner system

6. Injection Mould with international standard, like HASCO, etc.

7. Other custom Injection Mould

How To Custom My Own Injection Mould?

STEP | DETAIL |

1.Enquire /Quote | Discuss with customer after received buyer’s samples or drawings. |

2.Negotiation | Quality,Technique requests,Mould material,Price,Delivery time,Payment,etc. |

3.Place order | Sales contract + proforma invoice. |

4.prepaid | Customer T/T deposit to us to start to design mould. |

5.Mould design | We will communicate&exchange the opinion with customers during making drawing according to the sample. |

6.Design confirmation | Send mould drawing to customer for confirmation. |

7.Mould processing | Start to manufacture, we will sent photos to show tooling process. |

8.Sample confirm | Send the sample or as negotiation. |

9.Mass production | If customers need mass production plastic products, We can also offer. |

Description :

Mould Base | LKM,HASCO,DME |

Cavity/core material | 2738,2343,S130,2344,718,8407,S136,P20,KD-61,NAK80,H13 ect |

Cavity QTY | Single-cavity/Muti-cavity |

Runner | cold/hot runner |

Gate | Submarie gate,side/edge gate |

Mould lifetime | 500,000 shots |

Plastic part material | PC,PA,ABS,PVC,PA66,TPE,SAN,POM.etc |

Lead time | 20-40days based on different products |

Package | Wooden cases or cartons |

Port | Shanghai |

Design sofeware | UG/CAD/PROE |

-

Computer Network Repair Tool Kit Lan Utp Screwdriver Stripper Rj45 Connector

-

Wood handle leather DIY craft hand tools leather edge bevel tool

-

100% Original Brand New Discount Sale 2021 Can-Am Outlander X MR 1000R with Visco-4L

-

Fun ko doll Pop Venom Doll Action Figure pvc figure

-

New Arrivals 2021/2022 Adult Campagna T-Rex with Sound System Original Brand New Discount Sale

-

New 2021 Aero 3S T-Rex 3WD w/ Audio System Speakers

-

New Original 2021-2022 Aero 3S T-Rex Economical Aero 3S T-Rex

-

Wholesale Festool TS55 REBQ-Plus-FS (561655) 1200W 160mm (6.2") Plunge Cut Circular Saw with Rails

-

1m 3m 5m m 10m retractable tape measure metric/tape measure

-

BUY 2 GET 2 FREE HONDA Crf450r bike

Other Products

-

$3.00 / unit

$3.00 / unit