QTJ4-25 Ecological cement brick making machine price

-

Supplier: Guangxi Shenta Machinery Equipment Co., Ltd. -

Region: Guangxi, China -

Contact: Ms. Fang Huang -

Price: $9800.00 /set -

Min. Order: 1 set

| Pallet size: | 840*450*60mm; | Port: | Fangcheg,Guangzhou, Shenzhen, Shanghai, or other China port; |

| Operation: | 40s; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Certification: | CE, ISO, BV; | Raw materials: | cement,sand,stone,fly ash...; |

| Supply Ability: | 500 Set/Sets per Year; | Waranty: | one year; |

| Brick height: | 60~200mm; | Net weight: | 2.5t; |

| Packaging Detail: | Standard seaworthy packing suitable for sea long distance transportation; | Vibration Force: | 40kN; |

| Min.Order: | 1 set; | Brand Name: | Shenta; |

| Voltage power: | 22 kw; | Place of Origin: | Guangxi China; |

QTJ4-25 ecological concrete brick making machine

1.Characteristic of QTJ4-25 ecological concrete brick making machine

1. QTJ4-25 is the semi-automatic ecological concrete bricks making machine which we design & develop to meet the market demand, it is all mechanical transmission, has the features of compact structure, reliable operation, easy maintenance and low failure rate, it utilize the table vibration method to form the brick with excellent shape, dense frame and high strength, as well as lower cement comsumption.

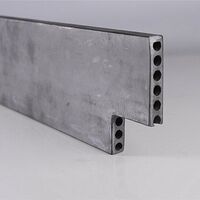

2. By changing different forming mold, the QTJ4-25 ecological concrete bricks making machine can produce different wall brick, hollow brick, solid brick, paver brick and so on, it is the best solution of the small construction engineering or the middle-small scale brick factory.

Main Specification QTJ4-25 ecological concrete bricks making machine

Operation Cycle (s) | 25~40 |

Vibration Force (Kn)

| 40 |

Brick Height(mm) | 60~200 | MainPower Capacity(Kw) | 16.5 |

| Vibration Frequency (rpm) | 4300 |

Pallet Dimension (mm)

|

840x450x60

|

Net Weight (Ton) | 2.5 | Main Machine Dimension(mm) | 3100*1530*2380 |

Power Source | 3Phase, 380V/50Hz (Special voltage & frequency is available according to your local power source.) | ||

Theoretic Productivity QTJ4-25 ecological concrete bricks making machine

Brick Type | Dimension | Blocks/Cycle | Blocks/Hour | Blocks/Shift | Remark |

Hollow Brick | 390*190*190mm | 4 | 360 | 2880 |  |

Porous Brick | 240*115*90mm | 9 | 810 | 6480 |  |

Interlock Brick | 225*112.5*60mm | 9 | 810 | 6480 |  |

Solid Brick | 240*115*53mm | 21 | 1890 | 15120 |  |

Note: Special brick model is available according to customers requirment

2.Advantage of ecological concrete bricks making machine

1. Automatic pallet and concrete feeding, it can save manpower and reduce the labor intensity, increase

3.Raw Material for ecological concrete bricks making machine

Our machine can adopt the following raw materials to make the good quality hollow brick, solid brick

and paver brick.

1.Sand: 30~40%; 2.Fly Ash or Additive: 0 ~10%;

3.Cement: 10~20%; 4.Crushed Stone (<5cm): 30~40%;

5.Construction Refuse or Mineral Slag.

4.Brick Sample for ecological concrete bricks making machine

hollow brick, solid brick, porous brick, paver brick, interlock brick,road traffic stone and so on.

5.Production flow of ecological concrete bricks making machine

Experienced in selling concrete brick machine to more than 30 different countries, we pack and load the machines well and prevent any damages during transportation, all the key parts are protect by the wooden

box.

6.Factory Ability:

1.Factory Area: 40,000 square meter;

2.Facility: CNC Lathe: 06 sets; Boring Lathe: 02 sets; Shaper: 02 sets; Milling Machine: 04 sets;

Press Brake: 02 units, CNC Flame Cutter: 01 set; Crane: 10 sets; Shot Blast Machine: 01 set.

7.Quality Control:

We adopt the high quality steel materials, and every process will have the strict inspection and test

to ensure the machine has perfect performance.

8.Certification:

9.Exhibitions:

We take parts in many exhibitions every year, such as Canton Fair in Guangzhou; India international engineering machinery, building materials machinery, mining machinery, engineering vehicles and

parts exhibition; International concrete technology and equipment exhibition in India; The ASEAN-China

Exposition in Nanning, etc.

10. our service

Pre-sale:

Analyze the customer’s need and factory layout design, confirm scale of operation;

Select the fitting choice;

Provide perfect solution to set up a factory.

Sales:

Help to set up the factory;

Provide free service of installation and commissioning;

Provide training for operator and maintenance person.

After-sale:

Help customers to establish production craft formula;

Provide the consultation all the time;

Supply moulds and parts all the time.

11.RFQ:

Q1: What is the standard packing for the brick machine?

A1: It depends. If necessary, wooden cases with fumigation are available.

Q2: If OEM and ODM services available?

A2: Yes. We can make the machines with customers’ brand and logo. With professional engineers, we also

can design and produce the machines according to customers’ requests.

Q3: What is the production lead time?

A3: Normally, if the brick machine are standard, it will be 35 to 40days. If not, the production lead time will be longer.

My dear friends, if you have any questions about the ecological concrete bricks making machine,please feel free to contact Alice:)

,

-

Wholesale manufacturers of modified four-wheel ATVs on the triangle track for snowboarding

-

QT3-15 pvc pallets

-

Excavator PC200-6 PC210LC-6 PC220-6 main safety valve 702-75-01200

-

Factory wholesale high quality plastic pvc tray

-

Hot sale 2019 pump pipe spare parts concrete pump

-

SINOCMP excavator accessories E365C 365C main control valve harness 231-1664 2311664

-

KDL galvanized steel roller

-

ppr pipe welding machine heating head/plastic pipe fitting mold socket

-

Refractoriness 1650 degrees Celsius high temperature silicon carbide plate for kiln

-

High-quality PVC trays used in brick making machines are recyclable