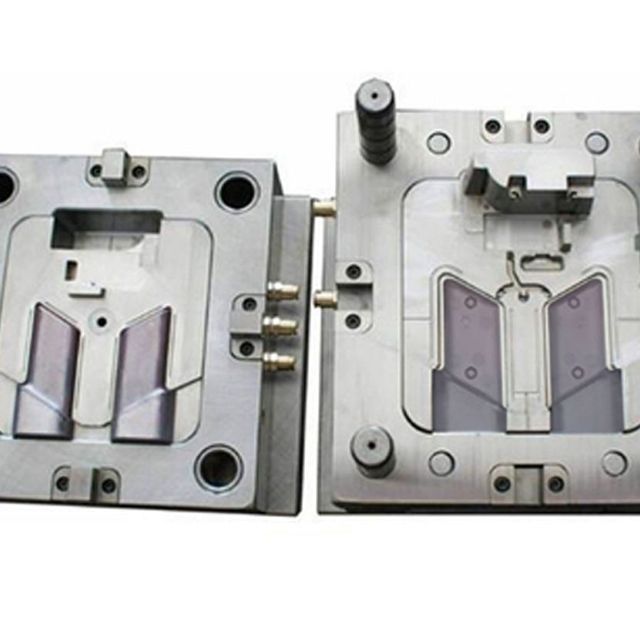

Hardware molds, plastic molds, stamping molds, metal surface laser hardening

-

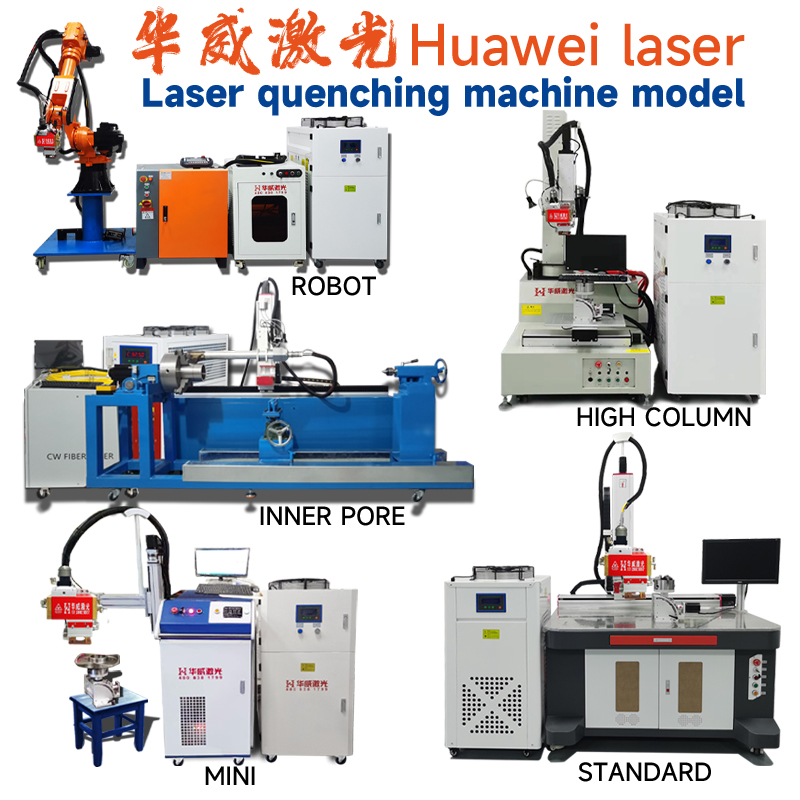

Supplier: Dongguan Huawei Laser Equipment Co., Ltd. -

Region: Guangdong, China -

Price: $30000.00 /piece -

Min. Order: 1 piece

| Health status: | new | Video outbound inspection: | if |

| Core component warranty: | 2 years | Applicable materials: | Metal |

| port: | Guangzhou | Laser light source brand: | and water conservancy |

| Supply capacity: | 1000 pieces per month | Showroom location: | China |

| Applicable industries: | Manufacturing plants, energy and mining | Core components: | laser |

| Whether CNC: | Yes | Laser type: | fiber-optic laser |

| Package preview: | Weight (kg): | 500kg | |

| Guide rail brand: | and water conservancy | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Control system brand: | and water conservancy | brand: | Huawei laser |

| Laser head brand: | and water conservancy | Place of origin: | Guangdong, China |

| Marketing type: | normal product | Warranty: | 1 year |

| Main selling points: | competitive price | Mechanical test report: | if |

Laser quenching is a quenching technology that uses laser to heat the material surface above the phase transition point. As the material cools, austenite transforms into martensite, hardening the surface of the material.

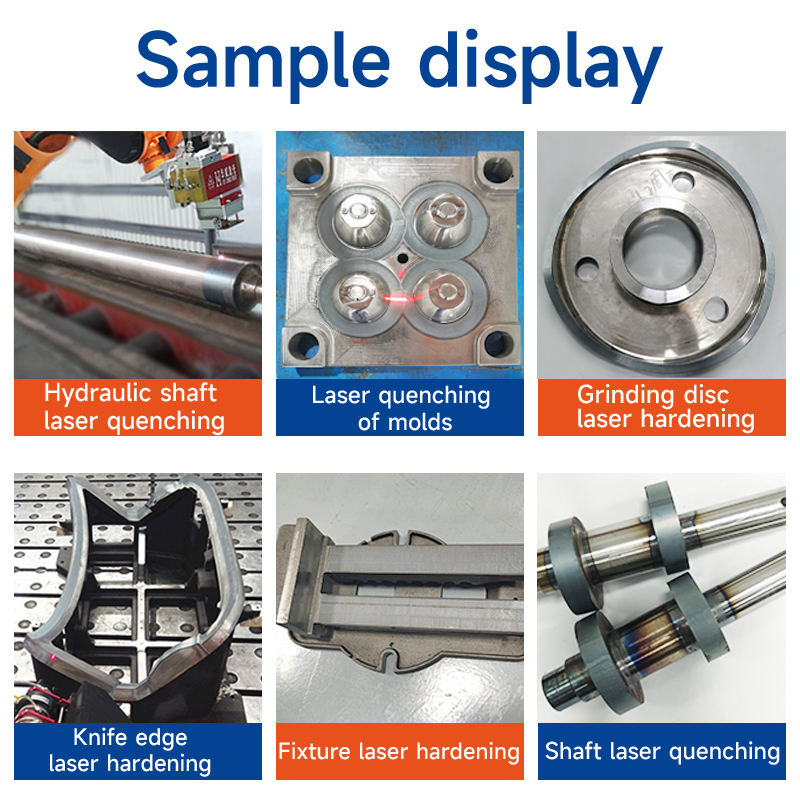

Practical application

Laser quenching technology can strengthen the surface of various guide rails, large gears, journals, cylinder walls, molds, shock absorbers, friction wheels, rollers, and roller parts. Suitable materials are medium to high carbon steel and cast iron.

Characteristics of laser quenching

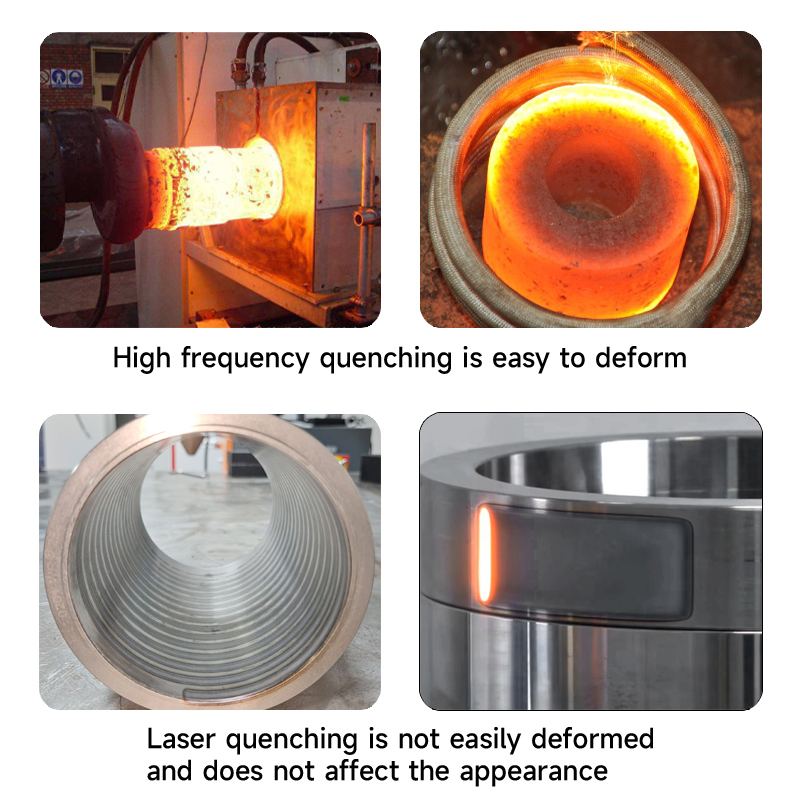

1. The quenched parts will not deform, and the thermal cycle process of laser quenching is fast.

2. The surface roughness is almost undamaged and a thin anti-oxidation protective coating is used.

3. Laser quenching will not crack, precise quantitative CNC quenching.

4. Precise CNC quenching can perform local, groove and groove quenching positioning.

5. Laser quenching is clean and efficient and does not require cooling media such as water or oil.

6. The quenching hardness is higher than the conventional method, the quenching layer structure is fine, and the strength and toughness are good.

7. Laser quenching is a rapid heating and self-induced cooling process that does not require furnace insulation or coolant quenching. It is a pollution-free, green and environmentally friendly heat treatment process that can easily achieve uniform quenching of the surface of large molds.

8. Due to the fast laser heating speed, small heat-affected zone, and surface scanning heating and quenching, that is, instant local heating and quenching, the processed mold deformation is very small.

9. Due to the small divergence angle and good directionality of the laser beam, the mold surface can be accurately partially quenched through the light guide system.

The depth of the hardened layer of laser surface quenching is generally 0.3-1.5mm.

-

-

The double drum feeder has heating and mixing functions. Suitable for laser cladding and metal 3D printing

-

High Tech Fiber Laser Hardening Equipment Large Cnc Laser Dressing Machine

-

Wholesale Cnc Laser Marking Machine Suppliers

-

High quality laser etched glass laser subsurface engraver for manufacturing plants

-

CATAIR piston cutting air compressor

-

Riton D-120 dmls denture printer 3d laser printer industrial 3d printer

-

100w Fiber Laser Marking Machine for Flat Glass Mirrors for Etching and Sandblasting

-

Professional Factory Manufacturing Milling CNC Thread Machine Screw Pump Rotor Cyclone Milling Machine

-

Laser heat treatment cladding machine metal mold bearing steel gear rail saw blade laser quenching machine

Other Products

-

$2500.00 / piece

$2500.00 / piece