Environmentally friendly disc microbubble aeration aerator

-

Supplier: Yixing Guochen Environmental Protection Equipment Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Euterpe Ding -

Price: $3.50 / 1 - 499 sets

$3.00 / >=500 sets -

Min. Order: 1 set

Product details

| Health status: | new | weight: | 0.43 kg |

| After-sales service provided: | Video Technical Support | brand: | / |

| Core components: | diaphragm | Showroom location: | not any |

| Core component warranty: | 1 year | Packaging Details: | cardboard |

| Plastic material: | ABS/PVC | payment terms: | Delivery of documents, delivery of documents, telegraphic transfer |

| Mechanical test report: | not available | Origin: | Chian |

| Marketing Type: | 2020 New Products | Main selling points: | long lasting |

| Material texture: | EPDM/silicone rubber | Warranty: | 1 year |

| Video outbound inspection: | if | model: | D215 |

| Package preview: | Supply capacity: | Annual output of 500,000 sets |

Product Description

Plate microporous aerator

The microporous aerator is mainly made of ABS engineering plastic and designed as a slightly raised arched surface. The diaphragm is made of special imported rubber (EPDM), the surface is anti-adhesion, and it is specially processed. Diaphragm holes are machined with CNC tools imported from Germany to ensure the quality and precision of the holes. When the aerator is oxygenated, four air supply tanks are designed on the main board, so that the incoming air can be buffered by the check valve and then sent directly to the center of the aerator head, ensuring that the diaphragm can be opened once and easily with low resistance. The mechanical assembly of the diaphragm is equipped with anti-lock ribs to ensure that the diaphragm will never fall off. When the air is inhaled, the micropores on the air distribution membrane expand by themselves to ensure the passage of air. When the aeration is stopped, the variable micropores on the air distribution membrane are closed. Because the variable micropores on the air distribution membrane expand and contract by themselves, the micropores passing through the aerator will not be blocked. Secondly, there is a check valve device on the bottom plate of the aerator to prevent the mixed liquid from entering the gas distribution branch pipe when the pipeline system stops the air supply, so as to prevent the mixed liquid from entering the branch pipe and being blocked. No special filtration is required for the incoming air, intermittent aeration is not clogged, the aeration is uniform, and the oxygen transfer efficiency is high.

detailed picture

Product Features 1. The gas diffusion rubber plate is made of high-quality synthetic rubber. The diameter of bubbles diffused from the rubber diaphragm is small, the area of the gas-liquid interface is large, the mass transfer rate is high, and the oxygenation efficiency is high. Compared with other existing aeration devices, it can greatly save power consumption and reduce the operating cost of sewage treatment. 2. There are a lot of self-closing holes on the rubber diaphragm. The holes can be opened and closed automatically when oxygenating and stopping operation. Therefore, there are no defects such as hole plugging and pollution. At the same time, the air entering the aerator does not need to be dedusted and purified. When the aerator stops running, the sewage mixture will not be poured back, which can reduce a lot of operating costs and maintenance workload. 3. Since the membrane microporous aerator can be fully distributed at the bottom of the aeration tank, the dissolved oxygen in the tank is uniform, so it can be applied to various tank types and depths, and can also be modified to improve the aeration effect of the original aeration tank. 4. The gas diffusion plate of the membrane microporous aerator is made of high-quality rubber and has excellent physical and mechanical properties. Trays, accessories, and air ducts are all made of engineering plastics, which are not afraid of corrosion and greatly reduce the workload of operation and maintenance. 5. The air duct adopts UPVC or ABS engineering plastic pipe (can be selected according to the user's needs), and the microporous aeration head is directly screwed on the air distribution pipe, which is easy to install and use, and is conducive to maintenance.

Specification

Name | ¢215 | ¢260 | ¢300 |

Working ventilation volume (m3/h) | 1-3 | 2-5 | 2-8 |

Design ventilation volume (m3/h) | 2 | 3 | 4 |

service area (m 2 hours) | 0.25-0.45 | 0.35-0.65 | 0.45-0.75 |

Oxygen utilization rate (%) | > 30 | > 30 | > 30 |

Oxygenation capacity (kgo2/h) | 0.15-0.35 | 0.18-0.45 | 0.25-0.55 |

Theoretical dynamic efficiency (kgo2/kW.H) | 6.5 | 6.5 | 6.5 |

Resistance loss (PA) | < 3000 | < 3000 | < 3000 |

Bubble size(mm) | 1-3 | 1-3 | 1-3 |

VIEW MORE

You may like

-

Fish aerator/oxygen breeding hose

-

Factory Wholesale Aquaculture Mud Crab Plastic Box For Fish Farm Soft Shell Crab Breeding Box- RAS System

-

Durable Microporous Nanobubble Diffuser Aeration Rubber Hose for Seafood Farm/Aquaculture

-

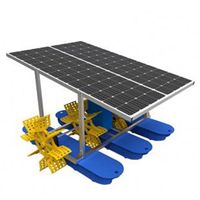

Hot Sale Fish/Shrimp Aquaculture Solar Pond Aerator

-

Hot selling 4 impellers floating 2hp aeration fish pond paddle wheel fish aeration machine 1hp

-

automatic shrimp feeder solar shrimp feeder

-

Solar Fish Farm Pond Fish Feeder Automatic Feeder

-

China solar fish pond water wheel aquaculture aeration machine for sale

-

High quality microbubble aquaculture nanobubble diffuser aeration sewage treatment rubber hose

-

Factory direct aeration pump fish pond farming shrimp farming floating aeration pump

Other Products

-

$0.70 / set

$0.70 / set -

$0.70 / set

$0.70 / set