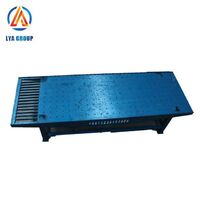

Concrete mold vibrating table machine paver block making vibrating table

-

Supplier: Henan HTX Group Co., Ltd. -

Region: Henan, China -

Contact: Ms Lisa Wang -

Price: $1000.00 / 1 - 4 pieces

$500.00 / >=5 pieces -

Min. Order: 1 piece

| type: | Internal | Voltage: | 220 volts |

| Marketing Type: | Hot Products of 2019 | size: | According to customer requirements |

| Unique selling point: | easy maintenance | frequency: | According to customer requirements |

| Flexible shaft length: | 1.5-3m | Packaging Details: | Interlocking Pavers or Tile Making Shaker Tables |

| Key words: | tile making vibrating table | weight: | 500 kg, 500 kg |

| Warranty: | 2 years | Showroom location: | Kenya |

| product name: | Interlocking Pavers or Tile Making Shaker Tables | Drive mode: | electric vibrator |

| Health status: | new | Origin: | Henan, China |

| Material: | iron plate | Applicable industries: | manufacturing plant |

| Vibration amplitude: | regular amplitude | Local service locations: | Kenya |

| Core components: | engine | Core component warranty: | 2 years |

| Dimensions (L*W*H): | 2000*1000*700 | feature: | durable |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Mechanical test report: | if |

| Product Keywords: | Shaker | usage: | Interlocking Pavers or Tile Making Shaker Tables |

| Video outbound inspection: | if | port: | Qingdao Shanghai Tianjin Ningbo |

| brand: | HTX |

Interlocking Pavers or Tile Making Shaker Tables

Concrete Paver Plastic Paver Mold Vibration Table

Our company's vibrating table adopts 1.53kw national standard vibrating motor, which has simple structure and low investment cost. It is the best choice for the production of concrete products such as pavement paver, curb stone and interlocking brick.

work process:

1. Rail material (concrete)

2. Pan mixer

3. Concrete in plastic mold

4. Vibrate on the table

5. Final pavers.

Technical Parameters

| Specifications | Dimensions (mm) | Power(KW) | Vibration capacity (T) |

| HTXMP-2000 | 2000*1000*700 | 1.5 | 1-2 |

| HTXMP-2500 | 2500*1000*700 | 2 | 1-2 |

| HTXMP-3000 | 3000*1000*700 | 3 | 1-2 |

Vibration table instructions

1. Installation:

a. Before installation, check whether the vibration motor is loose, and then fix the table legs on the prefabricated concrete foundation, pay attention to one side is higher and the other side is lower. Slope=5-60, then the mold will move from top to bottom.

b. Connect the wires (A, B, C, three phases) to the motor correctly, prohibit the motor from reversing, if it happens, stop immediately and change the wires until it rotates forward.

-

Petrol concrete vibrating machine for screed floors for sale

-

Frame type 6.5 horsepower gasoline engine concrete vibrator

-

Factory Direct Supply 2HP 3KW Concrete Machine Shaft Vibrator Electric Industrial Vibration Motor Small Poker Concrete Vibrator

-

ZN25 ZN35 ZN50 ZN70 Portable Electric 1500w Motorized Concrete Vibrator

-

Dynapac Claw Connector 38mm 45mm Concrete Inner Shaft Vibrator Hose Poker Rod

-

ISO 9001 Robin Engine Concrete Vibrator Shaft High Operating Efficiency Korea Philippines Interior Pakistan Nigeria UAE

-

Mini Concrete Vibrator with 1.5M Shaft Shaft Vibrator

-

Factory direct supply 220v 380v 0.55kw 0.75kw ZW-5 small flat-panel external electric concrete vibrator for brick making machine

-

Portable Electric Eccentric Concrete Vibrator High Speed | X-Men | Threaded Couplings

-

Concrete mould vibrating table machine paver block making vibrating table

Other Products

-

$500.00 - $1000.00 / piece

$500.00 - $1000.00 / piece