Japan TSUBAKI BB30-2K-K industrial cam clutch

-

Supplier: Shantou Rongtai Packing Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Xia Lin -

Price: $52.00 /piece -

Min. Order: 1 piece

| Applicable industries: | Manufacturing plant, printing plant, packaging and printing industry | Torque: | 140 Nm |

| Package preview: | brand: | Tsubaki | |

| type: | special | Accuracy class: | # |

| Aperture range: | 30 mm diameter | Material: | GCr15 |

| Packaging Details: | carton | model: | BB30-2K-K |

| payment terms: | L/C, Western Union, T/T |

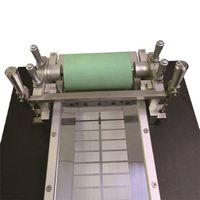

Japan TSUBAKI BB30-2K-K industrial cam clutch

The one-way clutch is a highly efficient mechanical device that utilizes the difference in axial rotation direction and rotation speed to prevent reverse rotation and ensure safety.

In order to create a more reliable one-way clutch, engineers spent years developing and improving the clutch, from the simple pillar type, to the ratchet and roller type, and finally to the cam type clutch, which became the mainstream. .

The TSUBAKI Cam Clutch introduced here is a cam-type one-way clutch that is the leading clutch today. BB series clutches have the bearing characteristics and dimensions of a #62 type ball bearing. This design is convenient for operation and installation. Ideal for general applications.

1. BB series cam clutches are designed for press fit installation.

2. The BB-1K-K and BB-2GD 1K-K series have a keyway on the inner ring. Keyways (except size 25) are manufactured to DIN 6885. 3 and BB40-1K-K and BB40-2GD 1K-K to DIN 6885. 1.

3. Both the inner and outer rings of BB-2K-K series have keyways. "-K" indicates the key shipped with the cam clutch.

4. Proper interference dimensions at the shaft and housing must be maintained for maximum bearing and clutch performance.

5. BB, BB-1K and BB-2K clutches are supported by bearings and supplied with grease, with dust seal protection against particles 0.25 mm and larger, while BB-2GD and BB-2GD-1K clutches are larger than the standard BB series 5 mm wide and has a special lip seal for effective protection against dust.

6. The arrow on the inner race indicates the direction of inner race engagement.

7. When installing the clutch, use a stamping tool of appropriate diameter to apply pressure evenly on the entire surface of the inner and outer rings.

8. Do not tap the clutch or apply other shocks to the clutch.

9. Make sure the housing is strong enough to withstand the pressure required for clutch press-fit installation.

10. Operating temperature range: –30°C to +100°C (please consult us if it exceeds this range).

lubricating

1. Since the grease has been applied before leaving the factory, there is no need to apply grease before use.

2. If the clutch is oil lubricated, it should always be inside the unit.

3. Do not use grease or lubricants that contain EP additives.

feature

1. Compact design

With the function of one-way clutch and bearing, it can effectively use the space in a small space.

2. Easy to install

For shaft or housing mounting, there are two types of locking - press lock and key lock.

3. Lifting torque capacity

There are a large number of cams arranged between the inner and outer rings, which can transmit more torque than shell roller clutches.

Application field

Wide range of applications from low speed to high speed, suitable for small, light load applications. Oil-sealed models are best for dusty, leak-proof applications. Torque: 29 to 260 N m (3.0 to 26.5 kgf m)

-

TMK agricultural bearings needle roller bearings for agricultural machinery 943/50 in stock

-

koyo Needle roller bearing NTC-1427 TC1427 NTA1427

-

CL42084 CL42082 One Way Clutch Bearing

-

18-24 Months Warranty Agricultural Machinery Square Hole Bearings 6205 6205-2RS 6205RS Special Planter

-

WB WR series automobile water pump bearing WR1630136

-

Combined Roller Bearings MR0031 MR0004 MR0034 MR0006 MR0008 MR0040 MR0016 MR0011

-

One-way needle roller clutch bearing assembly

-

HSN split cylindrical roller bearing LSE215BRHDFATL spot

-

OEM custom non-standard bearing NUKR56677.2 custom cam follower bearing NUKR 56677.2

-

Hub bearing 43560-26010 bearing VKBA7497 54KWH02 AUTO bearing

Other Products

-

$4600.00 / unit

$4600.00 / unit -

$89.00 / piece

$89.00 / piece