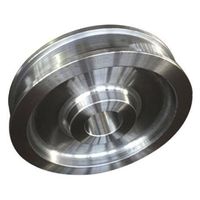

Railway Locomotive Wheel

-

Supplier: Jiangsu Railteco Equipment Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Joyce Jiang -

Price: $1000.00 /piece -

Min. Order: 1 piece

| Wheels Standards: | AAR, UIC, EN, GOST, IRIS, KSR, BS, JIS,TB; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,negotiable; |

| Certifications: | ISO9001, ISO14001, OHSAS18001; | Application: | Freight Wagon Wheels, Passenger Coach Wheels, Locomotive Wheels; |

| Packaging Detail: | Wooden cases; | Model Number: | Customer's Requirement; |

| Dimensions (L x W x H) (mm): | As Customer's Drawings; | Wheel Diameter: | 360mm to 1250mm; |

| Place of Origin: | Jiangsu China (Mainland); | Delivery Detail: | Shipped in 45 days after payment; |

| Type: | Wheels; | Supply Ability: | 5000 Piece/Pieces per Month; |

| Brand Name: | Railteco; | Material: | Forged wheel & cast wheel; |

| Port: | Shanghai; |

Package: four or five pcs in one bunch, packaged in Nylon Bag

or Wooden cases: export wooden cases with fumigation certifications

Delivery: within 45 days after order confirmed

Railteco Group(stock code:833120) was established in the year 2003, mainly engaged in design, manufacture and maintenance of railway wagons, vehicle parts, passenger coach interirors and railway equipment.

Q: Are you trading company or manufacturer ?

A: We are factory. We have production bases in Zhangjiagang, Changzhou, Suzhou and Anwei Tongling.

Q: How long is your delivery time?

A: For first batch 30 to 45 days, series batch according to customer's plan.

Q: Do you provide free design or drawings?

A: Yes, we have design ability, and we have an expert technology team for railway equipment.

Q: What is your terms of payment ?

A: T/T or L/C, we need at least 30% deposit, and balance before shipping.

If you have another question, pls feel free to contact us as below:

-

Rail Tamping Tools for all ranges of Plasser and Harsco Tampers CU 30 10840-FRIV

-

High Quality Custom Train Model Wheels Model Train Ho Scale For Sale

-

AAR standard railway locomotive diesel locomotive

-

SCZLHS hot sale aluminum alloy train window

-

High quality railway train parts

-

FRP train seat GRP SEATS FOR TRAIN METRO SEATS subway seat

-

China factory supply train wheel set mine wheel locomotive wheel set and train wheel

-

Timesower OEM ODM Railway Wheel Train Wheel Material Train Wheel

-

High Quality Railway Carriage Locomotive Train Wagons For Sale

-

Railway Diesel Locomotive Wagon Train Locomotive

Other Products

-

$62000.00 - $65000.00 / set

$62000.00 - $65000.00 / set -

$600000.00 / set

$600000.00 / set