Custom welded HSS shank extra long drill bit Hrc65 carbide drill bit

-

Supplier: Shenzhen Dawei Industrial Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Alisha Huang -

Price: $5.00 / >=10 pieces -

Min. Order: 10 pieces

Product details

| Supply capacity: | 300,000 pieces per day | Surface treatment: | polishing |

| port: | Shenzhen | ID: | Data Warehouse/Custom |

| coating: | As required | payment terms: | Western Union, T/T, Trade Assurance |

| Drilling type: | Straight Cut Carbide Point Mills | Handle: | High speed steel handle |

| product name: | welding drill | size: | Diameter 4-25mm / customized |

| Customization support: | OBM,ODM,OEM | application: | metal drilling |

| Packaging Details: | Plastic tube + carton | Certification: | CE, ROHS |

| flute: | 2 flutes | Human Resources Committee: | 55/60/65 |

| Surface treatment: | coating |

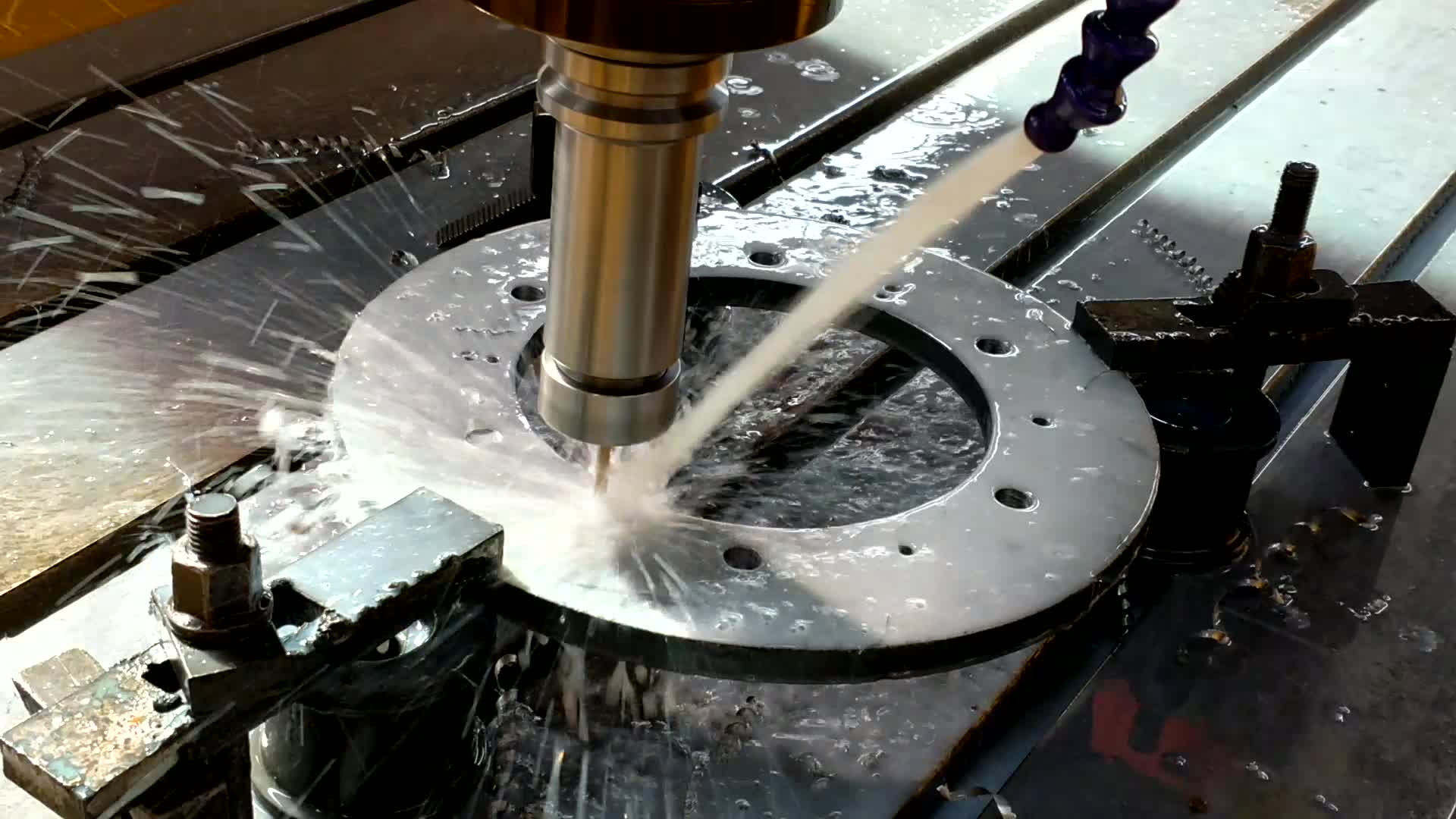

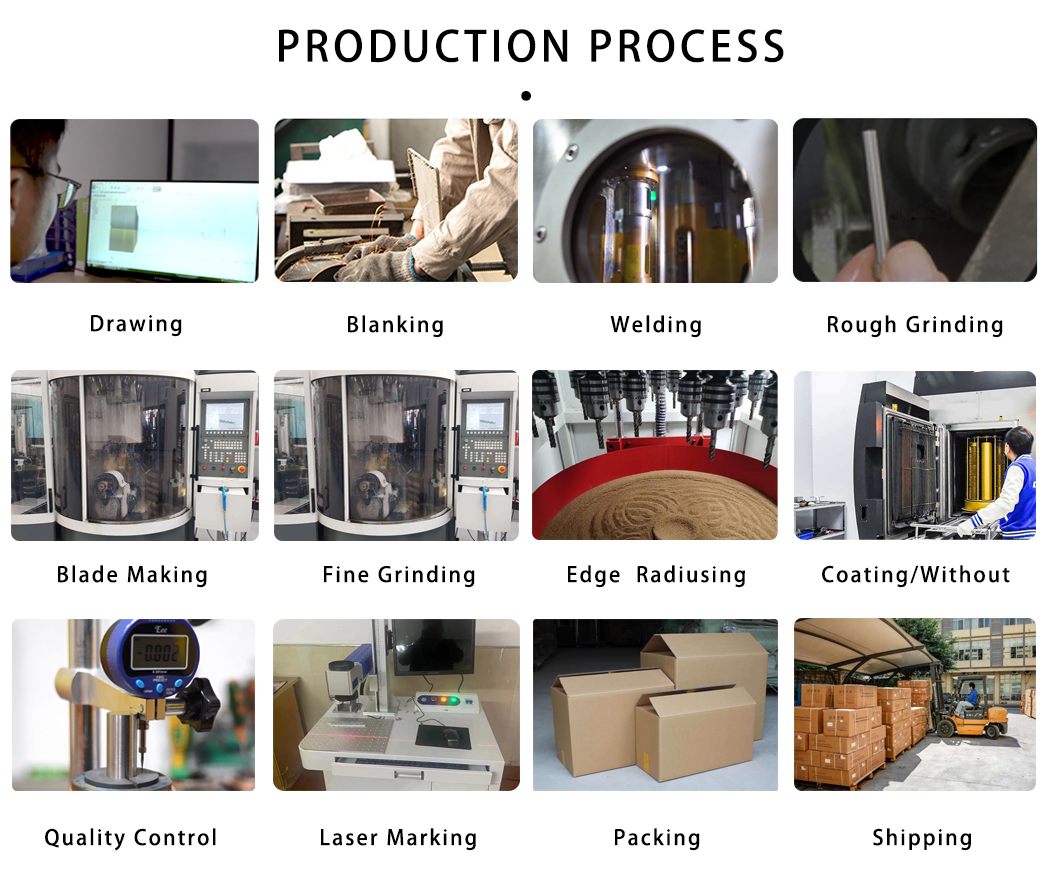

Our welding technology has a wide range of applications, not only for twist drills, but also for electric drills.

advantage:

Save costs and increase efficiency

Solve the problem of frequent disconnection

high precision

High hardness

good toughness

Personalization

high precision

High hardness

good toughness

Personalization

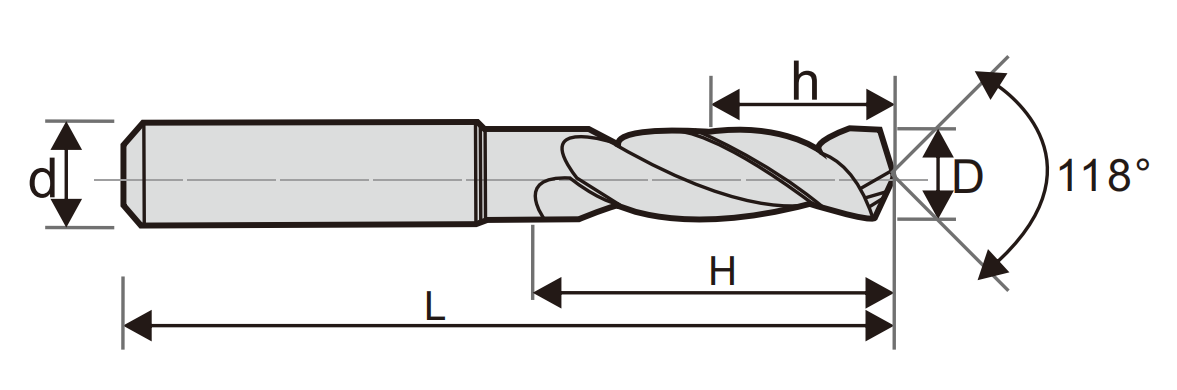

product specification

product specificationProduct Details

Product DetailsThe hardness/material/tolerance of the drill can be customized according to your requirements.

Applications

Applicationsworkpiece

40cr alloy structural steel, drill 13mm holes.

Compared

forward:Taiwan stainless steel drill bit, which can drill 30 holes at a time.

back:Using welded tungsten steel drill bits, 40 holes can be drilled at a time.

back:Using welded tungsten steel drill bits, 40 holes can be drilled at a time.

in conclusion

Work efficiency increased by 40%!

workpiece

6012 aluminum alloy, drill 15mm holes.

Compared

forward:It adopts solid carbide end mill with a service life of 150 holes.

back:Using welded tungsten steel drills, the same production efficiency saves 30% of the cost.

back:Using welded tungsten steel drills, the same production efficiency saves 30% of the cost.

in conclusion

Save 30% of the cost!

workpiece

Quartzite, drilled.

Compared

forward:Alloy steel + hard alloy drill is used, which is difficult to process.

back:Alloy steel + tungsten steel drill is adopted, which is convenient for drilling.

back:Alloy steel + tungsten steel drill is adopted, which is convenient for drilling.

in conclusion

For Quartzite!

.

.

.

VIEW MORE

You may like

-

High temperature carbide end mill

-

Rotary Carbide Diamond Grinding Head Electric Grinding Equipment Woodworking Carving Tool Iron Cutter Carbide Milling Cutter

-

BOMI BMHH-012 Hot Sale Single Edge Woodworking Single Edge Carbide End Mill

-

TAA Brand Drill Bit Metal Price Carbide Rotary File High Speed Milling Cutter Grinding Metal Abrasive Milling Cutter

-

133mm Wholesale Price OEM Five Wings Concave Pdc Water Well Drill Bits

-

BOMI BMNN-21 high precision sales factory custom CNC 4F solid carbide lathe cutting drill bit milling cutter

-

HRC50 Tungsten Carbide End Mill 2 Flute Radius CNC Carbide High Feed Round Nose Milling Cutter For Iron Castings

-

Carbide End Mill Set Square End Mill Head 4 Flute Mill Tungsten Carbide Cutting Tool

-

Oem dental bur 0.6mm Roland zirconia DLC

-

BOMI BMNN-21 Hot Selling Item Factory Custom CNC 4F Solid Carbide Lathe Cutting Drill Bit Milling Cutter