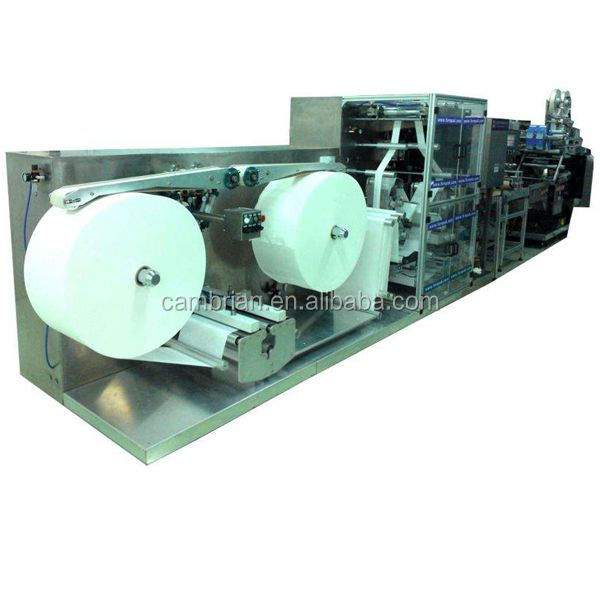

Large Capacity Automatic Wet Wipe Making Machine Automatic Wet Wipe Packaging Machine

-

Supplier: Zhengzhou Cambrian Machinery And Electronic Co., Ltd. -

Region: Henan, China -

Contact: Ms Susie Cheng -

Price: $12000.00 /set -

Min. Order: 1 set

| Health status: | new | Expand Wipe Size (Minimum): | 160*150mm |

| Packaging Details: | Wooden box, wet wipe machine | weight: | 3500 |

| Video shipment inspection: | if | Supply capacity: | 10 wet wipe machines per month |

| Warranty: | 1 year | capacity: | 35-120 bags/min |

| Marketing Type: | New Products 2020 | brand: | Wet wipe machine |

| payment terms: | L/C, Western Union, T/T | Voltage: | 220V |

| Showroom location: | Canada | Wet wipe machine frequency: | Wet wipe machine 50Hz |

| Mechanical test report: | if | Dimensions (L*W*H): | 3930*660*1400mm |

| Applicable industries: | Hotels, Machinery Repair Shops, Manufacturing Plants, Food & Beverage Plants, Home Use, Food & Beverage Stores | Folded wipe size (maximum): | 110*60mm |

| Core component warranty: | 1 year | Wet wipe machine type: | Wet tissue machine SJ-1 |

| strength: | 3200 | Origin: | Henan, China |

| Core components: | Programmable Controllers | Folded wipe size (minimum): | 80*50mm |

| aftersale service provided: | Wet wipe machine | port: | Qingdao or Shanghai port wet tissue machine |

| Expand wipe size (maximum): | 280*280mm | Machine material: | Stainless steel |

| Number of machines: | 6 wet wipe machines | Package preview: |

High Capacity Automatic Wet Wipe Making Machine With Best Price

Product Description Fully automatic wet wipe machine:

1). The structure of the equipment is neat, the performance is stable and reliable, and the operation is simple and easy to master.

2). The operation of this device is controlled by a microcomputer controller.

3). Equipped with high-precision Omron photoelectric tracking system.

4) The sealing and cutting position is very precise, and the sealing temperature is controlled separately.

Suitable for a variety of packaging materials, the seal is beautiful and firm.

5).Frequency conversion speed regulation is continuously adjusted, and the change is uninterrupted.

6). The automatic processing of the following processes is realized, namely: material folding, forming,

cutting; feeding; liquid medicine (disinfectant) spray packaging.

7). Fully automatic circulation system with liquid medicine content display function,

Spraying, liquid flow control, collection.

8). The liquid flow can be manually adjusted freely.

9). Equipped with a coding machine, which can automatically print the serial number of the production date.

The scope of application of the automatic wet wipe machine:

It is suitable for medical, sanitation, catering and other industries, and is used for the packaging of wine cotton.

Technical parameters of automatic wet wipe machine:

Model | SJ-1 Fully Automatic Computer Controlled Wet Folding Packing Machine | |

tissue size | expand | Length: 160-280mm Width: 150-280mm |

fold | Length: 80-110mm | |

Width: 50-60mm | ||

tissue layering | maximum | 1 vertical layer 4 cross layers |

bag size | Length: 120-200mm Width: 60-70mm | |

Film Width | Maximum 220mm | |

production capacity | 35-120 bags/min | |

total power | 220V 50HZ 3.2KW | |

Dimensions | Length*width*height: 3930*660*1400mm | |

work process: Non-woven fabric winding→folding→cutting→liquid filling→cutting→packaging. | ||

All technical parameters can be customized in our factory. | ||

Fully automatic wet wipe machine packing details:

Packed in wooden case with sealing tape.

Features of automatic wet wipe machine:

1. The equipment runs smoothly with low noise.

2. Beautiful appearance, convenient maintenance and coherent structure.

3. The feeding speed regulating device has obtained the national patent.

4. The sealing knife material is 40cr.

5. The machine is driven by a single frequency conversion motor, with stable operation and low failure rate. The contact information of the above accessories dealers is a commercial secret, and it is inconvenient to provide, please understand.

1. Pre-sale service:

Acting as a good advisor and assistant to customers, enabling them to obtain a good return on investment.

1>. Select the device model;

2>. Design and manufacture products according to the special requirements of customers;

3>. Train technicians for customers.

2. In-sale service:

1>. Pre-acceptance of products before delivery;

2>. Help customers draft solutions.

Three, after-sales service:

Provide thoughtful service to minimize customers' worries.

1>. Assist customers to prepare the first construction plan;

2>. Equipment installation and debugging;

3>. Training front-line operators;

4>. Check equipment;

5>. Take the initiative to attack and quickly troubleshoot;

6>. Provide perfect service;

7>. Provide technical exchange

-

Automatic Wet Wipes Making Machine Flushable Hand Sanitizing Wipes Standalone Mini Wet Wipes Making Machine

-

Wet wipes machine for beginners at factory price

-

Canned Wet Wipes Machine Tissue Making Machine With Perforated Line

-

Fully Automatic Car Wipes Cleaning Folding Machine Baby Wipes Packaging Machine

-

JBK-260 HAOYUAN Haoyuan baby wipes wet tissue manufacturing machinery automatic packaging machine production line

-

Fully Automatic Wet Wipes Baby Multipack Equipment Wet Wipes Making Machine

-

High Efficiency 30~120 Pieces Fully Automatic Wet Wipes Making Machine Wet Wipes Production Line

-

Baby Wipes Machinery Production Line Wet Wipes Making Machine Price

-

Automatic Wet Wipes Making Machine Clean Refreshing Baby Towel Tissue Making Packaging 12 Lane Production Line Price

-

Full Automatic Wet Wipes Machine Baby Wet Tissue Making Machine Production Line

Other Products

-

$370.00 / set

$370.00 / set -

$99.00 / piece

$99.00 / piece -

$150.00 / set

$150.00 / set -

$4000.00 / set

$4000.00 / set -

$3000.00 / set

$3000.00 / set -

$500.00 / set

$500.00 / set