API 5DP Drill Pipe Tool Couplings for Water Well Drilling

-

Supplier: Jinzhou City Tongshun Drilling Machine Co., Ltd. -

Region: Hebei, China -

Contact: Ms Lisa Lee -

Price: $1.00 /pair -

Min. Order: 1 pair

| thread type: | NC, FH, IF, REG | Weight (kg): | 25 |

| Warranty: | 3 months | Packaging Details: | Packed in carton or wooden case. |

| Certification: | API | Package preview: | |

| product name: | API 5DP Drill Pipe Tool Joints for Water Well Drilling | Video shipment inspection: | if |

| payment terms: | L/C, Western Union, T/T | Origin: | Hebei china |

| Applicable industries: | Energy and Mining | Marketing Type: | New Products 2020 |

| use: | drilling | size: | all sizes |

| application: | rock drilling | port: | Tianjin harbor |

| Showroom location: | Vietnam | Material: | 35CrMo/40Cr/4137H, Chromium |

| Product number: | TS-03061 | Connection Type: | male and female |

| Type of machine: | Drilling tool | Mechanical test report: | if |

| Processing type: | forging | Health status: | new |

| Supply capacity: | 5000 pairs per month | Special Process: | Conditioning |

| brand: | Tongshun | type: | drill pipe |

API 5DP Drill Pipe Tool Joints for Water Well Drilling

Product Description:

1. Outer diameter: 57mm-168mm

2. Material: 35CrMo/40Cr/4137H

3. Length: N: 235mm M: 195mm

4. Suitable for connecting 50mm drill pipe for drilling and geological drilling

5. Tool connector: NC26, NC31, NC38, NC40, NC46, NC50

---------------------------------------------------- ------------------------------------------

Specification:

| Drill pipe joint code | drill pipe | Drill pipe joint(mm) | ||||

| Specification | steel grade | outer diameter | Pin Tap ID | Tong Space by Pan Tap | Clamps for box taps | |

| NC26 | 2 3/8 inches | DZ5O, R780 | Ø86 | Ø45 | 178 | 203 |

| 2 3/8 inches | G105 | Ø85.7 | Ø44.5 | 178 | 203 | |

| NC31 | 2 7/8'' | ZD5, R780 | Ø104.8 | Ø50.8 | 232 | 280 |

| 2 7/8'' | G105 | Ø104.8 | Ø50.8 | 232 | 280 | |

| NC38 | 3 1/2 inches | DZ50, R780 | Ø127 | Ø65.09 | 248 | 310 |

| 3 1/2 inches | G105 | Ø127 | Ø61.9 | 248 | 310 | |

| NC46 | 4 1/2 inches | DZ50,R780 | Ø158.8 | Ø82.6 | 236 | 320 |

| 4 1/2 inches | G105 | Ø158.8 | Ø76.2 | 236 | 320 | |

| NC50 | 4 1/2 inches | G105 | Ø168.3 | Ø86 | 236 | 320 |

| 5'' | DZ50, R780 | Ø168.3 | Ø89/82.6 | 236 | 320 | |

| 5'' | G105 | Ø168.3 | Ø82.6 | 236 | 320 | |

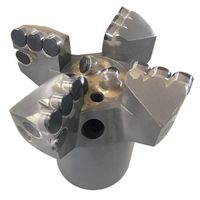

Tool connector picture:

production process:

Tool joint quality control:

1. Before the order is confirmed, the raw materials of the drill pipe and tool joint body should be ordered from the famous large steel enterprises in China.

2. Tool joints inspected by our QC staff and factory's own laboratory.

3. Each tool joint is non-destructively tested, cleaned and oiled before packing

4. Before the delivery of the tool joints, customers can send a QC or appoint a third party to check the quality, such as SGS, BV or others.

Precautions for the use of tool joints:

1. New tool joints should be coated with thread oil before connecting

2. Up and down at least 3 times before drilling

3. Hard bending and plastic wrapping can be processed according to the special requirements of customers

our service:

1. The tool joint is strictly in accordance with the ISO9001 standard

2. If you find quality problems within one month of the package being returned.

3. Perform all obligations and responsibilities strictly in accordance with the contract

4. 24 hours online customer service, feel free to contact us.

-

API standard drilling rig lifting tool sucker rod hook, excellent quality

-

311mm tci tri-cone drill bit, suitable for API ISO CE

-

High Quality 32mm 34mm 36mm 38mm Taper Drill Button Bits with 7, 8, 11, 12 Degrees

-

Mining Tools Multi Size High Quality 6 Inch 153mm Pdc Drill Bits with 4 Wings Drill Bits for Hard Rock Drilling

-

High quality and cheap hybrid drill bits, Tricone and PDC drill bits, drill bits for oil field and drilling

-

USED TRICONE DRILL BIT SCRAP FROM CHINA

-

Hand Drilled Integral Steel Rod of Small Hole Drilling Underground Mining

-

SML High Quality High Precision Spiral Bits for Wood Planer

-

Tungsten Carbide High Quality Conical Cross Bits

-

Made in China/Rock drill/cop1638/cop1838/cop1840/cop1132/cop1238/cop2560/cop2238