Forged steel racing engine connecting rod with high quality lower ends

-

Supplier: Dongguan Thriving Metal Parts Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Susan Shi -

Price: $10.00 /piece -

Min. Order: 1 piece

Product details

| Origin: | Guangdong, China | heat treatment: | Conditioning |

| brand: | OEM production | Material: | 35CrMo6, 42CrMo4, 4140, 4145 or as required |

| Packaging Details: | Standard package 1 piece per PE foam, or as your request for high quality bottom end forged steel engine racing connecting rod | QC: | 100% inspection before shipment |

| payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal | port: | Connecting Rod FOB Shenzhen |

| Warranty: | 12 months | payment terms: | 30% deposit, 70% before shipment |

| car model: | Guangzhou Jianhua | Certification: | ISO9001 |

| product name: | link | Certificate: | ISO9001 |

| delivery time: | Sample: 3-5 days; Production: 30-35 days | Supply capacity: | Connecting rods 100,000 pieces per month |

| Forging Tolerance: | +/-0.5 mm | MOQ: | 1 |

| application: | Cars, trucks, donkey carts, frac pumps, diesel engines, etc. |

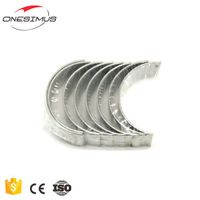

High quality bottom end forged steel engine racing connecting rod

product display

Product Description

High quality bottom end forged steel engine racing connecting rod

Quality Control Process:

Our quality control is from raw materials, forging, heat treatment, semi-finished product processing, finishing to assembly, every step is strictly controlled by our engineers, all of them have more than 10 years of engineering experience, specializing in metallurgy, forging, heat treatment respectively, non-destructive Inspection, machining and production inspection.

- These parts are for customization only, no stock; we can produce according to your drawings or samples.

- If you need, we can sign NDA (Non-disclosure Agreement) with you;

- Supply Ability: 100,000 pieces per month; small orders are welcome.

| Available Materials (Metal) | Available Materials (Plastic) |

| Aluminum alloys (aluminum, zinc, magnesium, titanium) | ABS, PC, ABS, PMMA (acrylic), Delrin, POM |

| Brass, bronze, beryllium, copper | PA (Nylon), PP, PE, TPO |

| Carbon steel, stainless steel, SPCC | Glass fiber reinforced plastic, Teflon |

| process | Surface treatment (finishing) |

| CNC machining (milling/turning), grinding | High polished, brushed, sand blasted, anodized |

| Sheet metal stamping, bending, welding, assembly | electroplating (nickel, chromium), powder coating, |

| Stamping, deep drawing, spinning | Lacquer painting, silk screen printing, pad printing |

| equipment | QC |

| CNC machining center (Fanuc, Makino) | CMM (3D coordinate measuring machine), 2.5D projector |

| CNC Turning Center/Lathe/Grinding Machine | Thread gauge, hardness, caliber. Closed Loop Quality Control System |

| Punching machines, spinning machines and hydraulic stretching machines | Third party inspection available upon request |

| Delivery time and packaging | application |

| Sample 7~15 days, production 15~25 days | Automotive Industry / Aerospace / Telecommunications Equipment |

| 3~5 days by express: DHL, FedEx, UPS, TNT, etc. | Medical/Marine/Architectural/Lighting Systems |

| Standard export carton with pallet. | Industrial equipment and parts, etc. |

more products

about Us

VIEW MORE

You may like

-

Toyota 2L/2L-T/3L Auto Parts R039A Bearing Connecting Rod Bearing

-

Adracing High Performance Titanium Racing and Modified Performance Linkages

-

Motorcycle Engine Forged Titanium Connecting Rod, Motorcycle Connecting Rod Kit

-

Forged Connecting Rod For Chevrolet Chevrolet Corvette C5 Camaro Pontiac GTO LS1 LS2 LS3 H Beam Connecting Rod

-

KUSIMA High Quality Land Rover Range Rover 3.0 Diesel Connecting Rod for Jaguar 306DT CONROD TDV6 X 1 STD

-

Suitable for Hyundai Elantra Power Sonata Kia Serrato R&F G4NA G4NB NU engine cylinder head camshaft large tile cover

-

High Strength and Lightweight Custom Forged CNC Machining Aluminum Bar High Performance Connecting Rod Engine Connecting Rod

Other Products

-

$0.10 - $0.50 / piece

$0.10 - $0.50 / piece -

$0.10 / piece

$0.10 / piece

Related Search

racing car connecting rods

elephant chain hoist with high quality

automatic gypsum powder equipment with high quality

best price with high qualiti ku lnb suppliers

u bolt with high quality

blowing mold with high quality

antenna with high quality

motocycl tyre with high qualiti suppliers

2015 high quality dead end clamps preformed guy grip cable fitting

high quality open end zipper