Fan/pig heating equipment for industrial poultry heating

-

Supplier: Qingzhou Boost Temperature Control Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Ms Feng Zhang -

Price: $180.00 / 1 - 4 sets

$120.00 / >=5 sets -

Min. Order: 1 set

Product details

| payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram | Material: | Stainless steel |

| Showroom location: | not any | Supply capacity: | 20000 sets per month |

| weight: | different models | Core components: | Pressure vessels, motors, bearings, gears, pumps, gearboxes, engines, PLCs |

| type: | air heater | Mechanical test report: | if |

| product name: | Industrial Poultry Heater / Pig Heating Equipment | Protection class: | IP*4D |

| Warranty: | 1 year | size: | custom made |

| Air output: | 1100 cubic meters / hour | After-sales service provided: | Video technical support, online support |

| Certification: | CE certification | Voltage: | 220V |

| Dimensions (L*W*H): | custom made | Energy source: | diesel engine |

| Packaging Details: | Regular packing is carton packing | brand: | Promote |

| After warranty service: | Video technical support, online support | Local service location: | not any |

| Fuel consumption: | 1.8-4L/hour | Main selling points: | competitive price |

| Video shipment inspection: | if | Origin: | China |

| port: | Qingdao | Health status: | new |

| Core component warranty: | 1 year | strength: | 50 kW |

| Package preview: | Applicable industries: | Hotels, clothing stores, building supplies stores, machinery repair shops, manufacturing plants, food and beverage factories, farms, restaurants, home use, retail, food stores, printing shops, construction, energy and mining, food and beverage stores, advertising agencies | |

| application: | Greenhouse, poultry house heating | fuel: | diesel engine |

| Marketing Type: | New Products 2020 |

Product Description

Industrial Poultry Heater / Pig Heating Equipment

We have many models, please tell me your requirements, then we will recommend the suitable model for you

Model | BSTAH-20 | BSTAH-30 | BSTAH-50 | BSTAH-70 | BSTAH-100 |

strength | 20 kW | 30 kW | 50 kW | 70kw | 100 kW |

air volume | 550 cubic meters / hour | 720 cubic meters / hour | 1100 cubic meters / hour | 1300 cubic meters / hour | 1700 cubic meters / hour |

fuel consumption | 1.0 l/h-1.7 l/h | 1.5 l/h - 2.4 l/h | 2.8 l/h - 4 l/h | 3.5 l/h - 5.4 l/h | 4.0 liters/hour-8.0 liters/hour |

Fuel tank capacity | 19L | 19L | 38L | 65L | 65L |

Net weight/Gross weight | 19kg/20kg | 20kg/21kg | 27kg/28kg | 41kg/42kg | 41kg/42kg |

Package Size | 750*315*415 mm | 920*460*630 mm | 1050*490*615 mm | 1130*480*655 mm | 1130*480*655 mm |

Voltage/Hz | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ |

detailed image

engine

1. Pure copper motor 2. Class I insulation safety 3. Fully enclosed waterproof and dustproof: IPX4 4. Leakage protection, large current grounding wire 5. Pure aluminum shell anti-rust, fast heat dissipation

Big wind, big heat

1. Special baking paint coating, anti-corrosion and corrosion resistance 2. High-strength galvanized sheet, high hardness, impact resistance 3. Convection heat insulation, not hot 4. Stainless steel combustion cylinder, high temperature resistance

One-button intelligent constant temperature control

1. Dual-display computer version 2. Button numerical control panel, more precise control, more complete combustion 3. External temperature control probe 4. Precise temperature control

tank

Thickened 8mm steel fuel tank visual oil dipstick

working pressure gauge

The internal air pressure is adjusted according to the environment. The machine is ready to useoptimal pressure, if adjustment is required, please contact a technician for assistance.

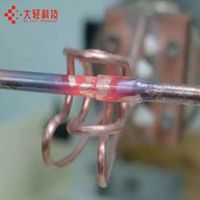

Imported gear pump

Imported gear pump, intelligent temperature control, more powerful and more secure.

The fuel filter bowl is used to filter impurities in the oil to ensure the service life

Inlet nozzle

Inlet nozzle

application

tech tips

1. Maintenance skills

1. Every 500 hours is a maintenance cycle. If the working environment is harsh (farms, places with a lot of dust, etc.), the maintenance cycle needs to be shortened to 250 hours

2. Inspection items

2.1.Clean or replace the filter sponge in the air pump (IEntrance Exit)

2.2.Clean or replace the oil suction filter

2.3.Clean the ignition needle (brush off carbon deposits on the needle due to ignition)

2.4.Clean the fuel tank, open the oil drain nut at the bottom of the fuel tank, drain the internal residue, and clean the inside of the fuel tank with clean diesel or kerosene

Comment:

Filter sponges, oil suction filter elements, and oil nozzles are vulnerable parts, and are not guaranteed for free within one year

2. Installation tips

a handle

B: Down the steel pipe

C: cotter pin

D: Nut 8PCS

E: Nut

F: wheel

G: flat pad

H: axle

One: fuel tank

J: screw

VIEW MORE

You may like

-

Laboratory vacuum drying oven CE certification

-

Cast brass/copper heater

-

SFM Min 12v 24v 36v 48v 3D printer electric heating tube cartridge heater

-

220v 2500w plastic extruder heater electric mica heating tape

-

Manufacturer of metal coil induction electric heating systems

-

Electric Quartz Radiant Heater Custom Size White Quartz Heater

-

Industrial electric furnace induction heating coil

-

Straight Stainless Steel Tube Heaters for Ovens

-

12-48V 2500W ZVS Induction Heating Module Board High Frequency Durable Professional PCB Board Replacement

-

5-12V 120W Induction Hot Plate Flyback Driver Heater DIY Cooker + Ignition Coil

Other Products

-

$490.00 - $1000.00 / set

$490.00 - $1000.00 / set -

$95.00 - $105.00 / set

$95.00 - $105.00 / set

Related Search

hydraulic equipment for industrial vehicles

equipment for industrial bakery

equip for heat radiat suppliers

insulation for industrial heat treating

psa n2 generator for industry

tool for industry

equipment for popcorn

the equipment for glass polishing

energi save equip for home suppliers

equipment for fish sausage suppliers