30 m3/h mobile and compact, the most economical concrete plant on the market!

-

Supplier: CONSTMACH MAKINA ITHALAT IHRACAT LIMITED SIRKETI -

Region: -, Turkey -

Contact: Mr. Emre Ciplak -

Price: $1000.00 /unit -

Min. Order: 1 unit

Product details

| Power Type: | electrical | Certification: | CE, ISO |

| Warranty: | 2 years | After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| Mixer Type: | Planetary/Single Shaft/Disc | Supply capacity: | 4 units per month |

| brand: | Constermach | Packaging Details: | Fully packaged to avoid any physical-aesthetic damage during loading-transporting and unloading. |

| Coating Thickness: | 150 microns | Applicable industries: | Building Materials Stores, Manufacturing Plants, Construction Engineering, Energy & Mining |

| Warranty: | 2 years | After-sales service provided: | Video technical support, on-site installation and commissioning training, on-site maintenance and repair services, free spare parts, online support |

| Video external inspection: | if | Control cabinet: | Insulation |

| Health status: | new | payment terms: | letter of credit, wire transfer |

| Control Type: | Fully automatic | Marketing Type: | New Products 2020 |

| Core Components Warranty: | 2 years | Type of machine: | batching machine |

| Packaging Preview: | Air compressor: | present | |

| Dimensions (L*W*H): | 8 x 2,2 x 2,2 | Local service location: | Turkey, France, Peru, Spain, Morocco, Chile, Romania |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | Showroom location: | Turkey, France, Spain |

| port: | from any Turkish port | capacity: | 30 m3/h |

| place of origin; place of origin: | Izmir, Turkey | weight: | 8 tons |

| Mechanical test report: | if | strength: | 55 kW |

Product Description

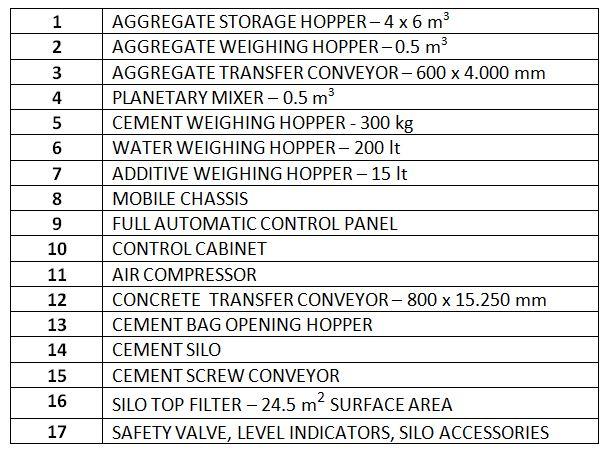

Technical Specifications of Mobile and Compact Concrete Batching Plants

1- Polymer hopper:

Volume: 24 m3

Number of compartments: 4 x 6 m3

Body material: St 37 – 5-6 mm, bent plate. Number of discharge doors: 4

Discharge door control: electro-pneumatic

Gate cylinder: 800 x 300 mm, brand: Rexroth. The body is reinforced to prevent deformation. Sand chamber vibrators: 2 pcs, 0.37 kW vibrator brand: OLI (origin: Italy), model: MVE 300/3 Air accumulators present. There are service platforms on both sides.

Number of compartments: 4 x 6 m3

Body material: St 37 – 5-6 mm, bent plate. Number of discharge doors: 4

Discharge door control: electro-pneumatic

Gate cylinder: 800 x 300 mm, brand: Rexroth. The body is reinforced to prevent deformation. Sand chamber vibrators: 2 pcs, 0.37 kW vibrator brand: OLI (origin: Italy), model: MVE 300/3 Air accumulators present. There are service platforms on both sides.

- 2 - Polymer Hopper:

Weighing capacity: 0.5 m3

Body material: St 37 – 5 mm sheet metal

Vibrator: 1, 0.37 kW,

Vibrator brand: OLI (origin: Italy), model: MVE 300/3. Equipped with load cells: 4, 2.000 kg/each, brand: ESIT

Body material: St 37 – 5 mm sheet metal

Vibrator: 1, 0.37 kW,

Vibrator brand: OLI (origin: Italy), model: MVE 300/3. Equipped with load cells: 4, 2.000 kg/each, brand: ESIT

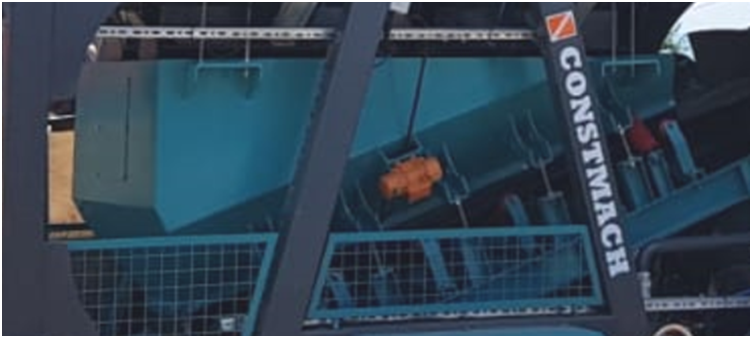

- 3- Aggregate Weighing and Transfer Conveyor:

Conveyor dimensions: 600 x 4.000 mm

Chassis material: NPU 140mm steel C-profile. Electric motor: 5.5 kW, 1450 rpm, EMTAŞ brand. Gearbox brand: DISSAN, heavy duty type. Bearings: FAG or SKF brand. Use heavy duty housings. Belt Rubber: Quality EP 125, Layers: 4, Belt Rubber Thickness: 10mm

Belt rubber brand: DERBY

There is an emergency stop button.

Drive drum: Ø320mm, 5mm thick. The drive drum is covered with rubber.

Chassis material: NPU 140mm steel C-profile. Electric motor: 5.5 kW, 1450 rpm, EMTAŞ brand. Gearbox brand: DISSAN, heavy duty type. Bearings: FAG or SKF brand. Use heavy duty housings. Belt Rubber: Quality EP 125, Layers: 4, Belt Rubber Thickness: 10mm

Belt rubber brand: DERBY

There is an emergency stop button.

Drive drum: Ø320mm, 5mm thick. The drive drum is covered with rubber.

- 4- Mixer: Planetary Mixer 750/500

Dry capacity: 750 liters

Compacted concrete capacity: 500 liters

Blender motor: 18.5 kW, 1450 rpm (GAMAK or equivalent - Turkey), efficiency class: IE3. Gearbox: Heavy duty type, (PGR brand - Turkey). Wear resistant HARDOX 450 plates (SSAB - Sweden) or XAR 500 (Germany) for bottom and side liners and mixing arms, thickness 15 mm, min. hardness 450 HBW; stirring and scraper in NI-HARD cast iron, hardness: 700 HBW.

Compacted concrete capacity: 500 liters

Blender motor: 18.5 kW, 1450 rpm (GAMAK or equivalent - Turkey), efficiency class: IE3. Gearbox: Heavy duty type, (PGR brand - Turkey). Wear resistant HARDOX 450 plates (SSAB - Sweden) or XAR 500 (Germany) for bottom and side liners and mixing arms, thickness 15 mm, min. hardness 450 HBW; stirring and scraper in NI-HARD cast iron, hardness: 700 HBW.

- 5- Cement weighing hopper

Weighing capacity: 300 kg Hopper material: St 37 – 4 mm Cement is discharged through a butterfly valve with pneumatic actuator control. (WAM or OZB brand) The connection to the mixer is done with a flexible hose. Equipped with load cells, 3 pieces of 1000 kg each. (Brand: ESIT) Vibrator: 1 pcs, 0.18 kW, (Brand: OLI - ITALY), Model: 200/3

- 6- Water weighing hopper: hot dip galvanized

Weighing capacity: 200 lt Hopper material: St 37 – 4 mm Water is drained through a butterfly valve with pneumatic actuator control. (WAM or OZB brand) with load cell, 3 pcs, 1000kg/pc. (Brand: ESIT)

- 7-Additive weighing hopper: hot-dip galvanizing

Weighing capacity: 20 lt Hopper material: St 37 – 4 mm Water is drained through a butterfly valve with pneumatic actuator control. (WAM or OZB brand) with load cell, 1 pc, 100 kg. (Brand: ESIT)

- 8- Mobile chassis

Chassis material: 100 x 150 x 5 mm steel profiles Walking platform, handrails and ladders are galvanized All mixers and weigh hoppers are ready for use and CE compliant. The chassis has 1 axle and 2 tires.

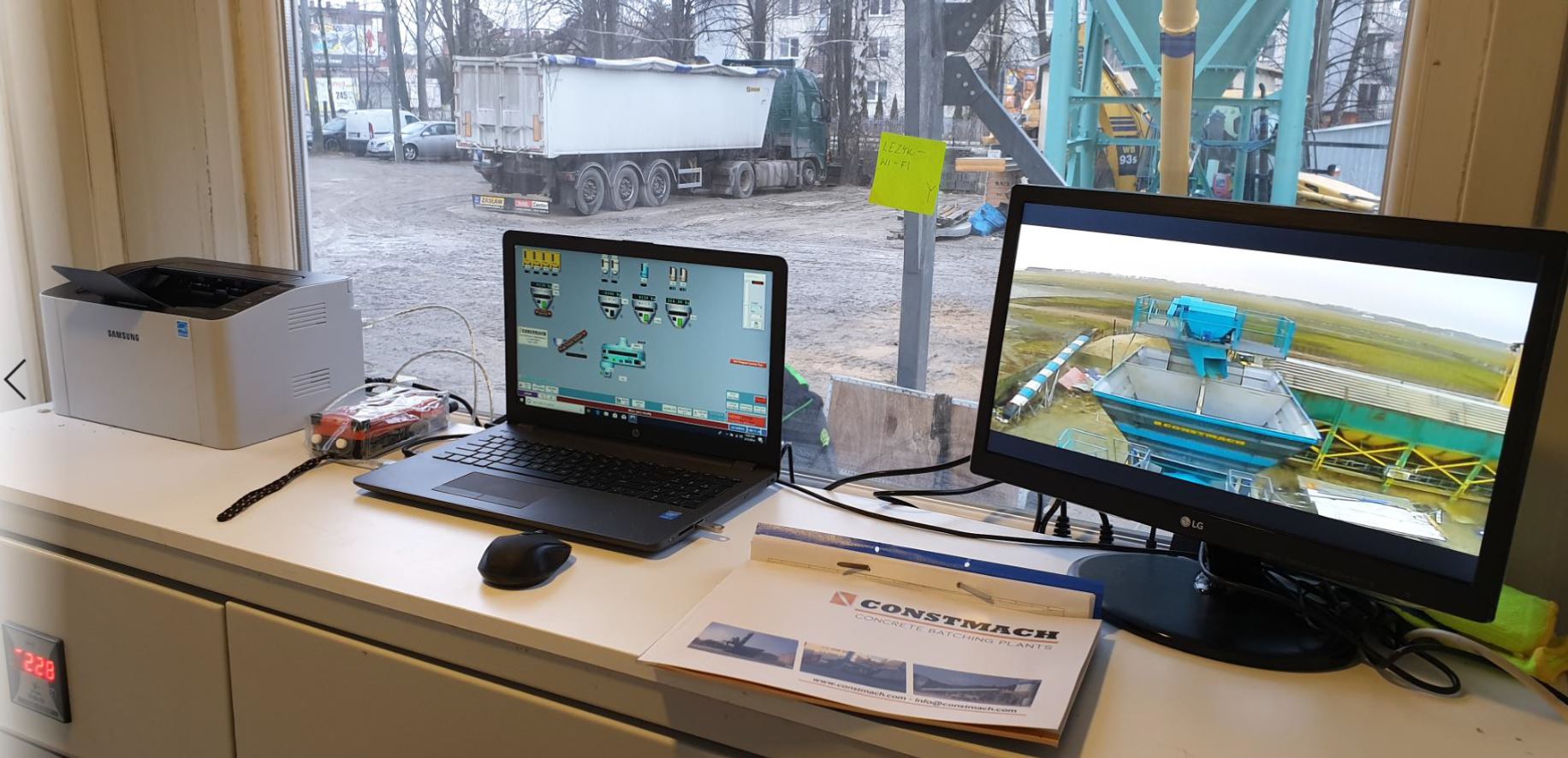

- 9- Automation System:

The plant is fully automated and the system is controlled on a PC.

The automated system includes:

* Power panel and control panel

* PLC (SIEMENS or SCHNEIDIER brand)

* software

* Computer, screen and plotter

* Electronic components are SIEMENS and SCHNEIDER brands.

- 10- Control cabinet:

Dimensions: 2.000 x 1.600 x 2.200 mm Walls are made of 40 mm insulating sandwich panels.

- 11 - Air Compressor:

Compressed air volume: 200 liters Brand: TAMSAN, Origin: Turkey

Type: Piston compressor with drive

Body: GG-26 casting

Motor power: 3kw

Maximum air pressure: 8 bar

- 12- Concrete Conveyor:

Conveyor Dimensions: 800 x 15.250 mm

Chassis Material: Curved Sheet Metal – 4mm

Electric Motor: 11 kW, 1450 rpm, GAMAK Brand Gearbox Brand: POLAT, Heavy Duty Bearing: Use FAG or SKF Brand Heavy Duty Bearing Box. Belt Rubber: Quality EP 125, Layers: 4,

Belt rubber thickness: 10 mm

Belt rubber brand: BANTSAN

Includes emergency stop button.

Drive drum: Ø273mm, 5mm thick. The drive drum is covered with rubber.

- 13- Cement bag opening hopper: optional

Capacity: 1 m3Body sheet and thickness: St 37 – 4-5mm with ladders, platforms and handrails. An open bag grill with sharp edges is located on top of the hopper.

- 14- Cement silo: optional

Type: Welded or Bolted Capacity: 50 tons (other options are possible) Cone Material and Thickness: St 37 - 6 mm

Body material and thickness: St 37 – 4-5-6 mm Roof material and thickness: St 37 – 4- mm Charging tube: Ø 114 mm

There are deck ladders from bottom to top. The silo roof is surrounded by handrails according to CE standard. The body is reinforced with NPU steel profiles. The silo legs are long enough that there is no need to build concrete legs. The silo is equipped with an air system for filters and air nozzles.

- 15- Screw conveyor:

Screw conveyors of the same size have open bag hoppers or cement silos.

Dimensions: Ø 219 x 5.500 mm

Motor: 9kw

Brand: WAM or OZB

- 16- Silo top filter: optional silo

Surface area: 18 m2

There are 3 solenoid valves with pneumatic cleaning.

Air consumption 4,5 Nmc/h

Brand: WAM or OZB

- 17- Safety Valves, Level Indicators, Silo Accessories

There is a pressure relief valve at the top of the silo.

There are level indicators for controlling the cement level in the silo: 2 for maximum and minimum level.

The silo discharge port has a butter fly valve with a manual lever.

There are air nozzles with air fittings.

Silo accessories brand: WAM or OZBdetailed image

You can see many different images below. For railway images please visit our webpagewww.constmach.com

VIEW MORE

You may like

-

Fully automatic small mobile ready-made dry-mix concrete batching plant capacity 50m3/h to 240m3/h concrete batching machine factory

-

Mobile Concrete Mixing Plant / Concrete Plant Price

-

Pld 800 Liters Pld800 0.8M3 Chinese automatic ready mixed concrete batching machine Pld800 1200 1600

-

Mobile concrete batching plant for sale in Malaysia

-

Factory manufacturer hzs 25 to 240 m3/h Small portable ready mixed concrete batching plant

-

JZM500 Construction Equipment Capacity 25m3/h Drum Mobile Concrete Plant Batching Plant

-

60m3/h mobile concrete batching plant HZS60

-

Cement advanced electrical wet mix continuous automatic stationary small concrete batching plant

-

China famous brand Fully Automatic Belt Conveyor Type HZS120 concrete batching plant for sale

-

Automatic mini concrete batching mixer plant price for sale

Other Products

-

$1000.00 / unit

$1000.00 / unit -

$1000.00 / unit

$1000.00 / unit

Related Search

mobil and disabl

and the raw cut

control panel in the well and tank

the best car polish and wax

most popular mobil phone network suppliers

the most popular sand machine

mobil holder and usb hub

in the retail and industry suppliers

mobil drill and workov rig suppliers

rope and the rope knitting machines