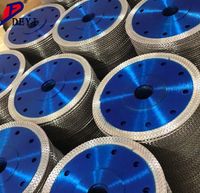

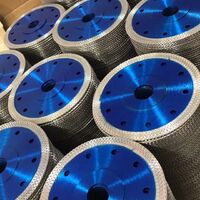

Z-Lion DEKTON Ceramic Porcelain Diamond Saw Blades

-

Supplier: Xiamen ZL Diamond Technology Co., Ltd. -

Region: Fujian, China -

Contact: Ms Winnie Zhang -

Price: $3.00 / >=10 pieces -

Min. Order: 10 pieces

| Product Name: | DEKTON Ceramic Porcelain Diamond Saw Blades; | Type: | Machine Blade; |

| Cutting direction: | Vertical cut, Horizontal cut; | Delivery Detail: | Shipped in 14 days after payment; |

| Supply Ability: | 50000 Piece/Pieces per Month; | Size: | 10"-14"; |

| Compaction Technique: | Cold-pressing, hot-pressing, sintered; | Packaging Detail: | 1.carton box 2.or as customer required; |

| Base body & Matrix type: | Normal, Silent; | Manufacturing Art: | Welding,Silver Welding,etc; |

| Blade Material: | ALLOY STEEL; | Diamond saw Blanks: | Wide slot, Narrow slot, Narrow slot with key hole,Thin-type; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,Paypal; | Place of Origin: | Fujian China (Mainland); |

| Perfromance comparison: | Sharp or wearable diamond blade; | Model Number: | DEKTON; |

| Port: | XIAMEN, CHINA; | Brand Name: | Z-LION; |

| Finishing: | Ti-coated; | Application: | diamond cutting blades for ceramic; |

Product description

Advantage:

These diamond blades are excellent for cutting granite,stone and other masonry materials. These diamond granite saw blades will give you the fastest cutting performance and long life while saving you money and making your job easier.

Specification:

1) Application:granite, engineered stone and ceramic tile

2) Both wet and dry cutting; turbo teeth enable the blade to be sharp

3) Competitive price, quick, smooth cutting and long life

Diameter | Hole | L | T | H | s | |

Inch | mm | |||||

10 | 250 | 50/60 | 41.9/39.3 | 8 | 2.4 | 19 |

12 | 300 | 44.8/42.4 | 21 | |||

14 | 350 | 42.7/40.9 | 26 | |||

Guides For Using:

1. Ware an apron, a gauze mask and safety glasses first. Connect a Back Holder to the Polisher or Angle Grinder, and attach a Wet Pad of grit 50 to the Back Holder.

2. Moving two passes across and one pass up and down is a good technique. Make sure all prior scratches are removed before moving onto the next grit.Repeat the same process using all 7 pads to complete the polishing process.Polish from grit 50 to grit 3000 respectively. Do not skip.

3. If you want to achieve the best polishing results on granite or other natural stones, use Buff Pad as the last step. Wet the workpiece and run the Buff Pad semi-wet with very low water. When the water is consumed, the process is complete. Repeat as necessary to improve the luster and achieve the mirror effect result.

4. Dry pads are designed for use on jobs without using water, but polishing with a small amount of water to wet the object surface will ultimately reach a better result.

Packaging

Company Introduction

Established in 2002, Xiamen ZL Diamond Technology Co., Ltd. is a professional company specialized in research, development, production and sale of diamond tools. Our company focus on innovation of products, by far, we have applied for 53 pieces of demestic and international patents. We provide ODM and OEM service for 5 top international brand in diamond tools industry, we also invented the world first finest 2mm diameter diamond wire saw.

Over 10 years exporting experiences, our products have been sold to Europe, North and South American, South-east Asia, Middle-east, Africa, etc.

Certificates

-

Glass cutting blade 100mm ultra-thin saw blade jade crystal wine bottle grinding chamfering cutting blade glass cutting blade

-

120 British 1200mm meat and bone cutting butcher band saw blade machine for fast cutting meat and bone saw blade

-

High quality tableware Mania imported band saw blades food processing bone and frozen meat cutting butcher saw blades

-

4 Inch 4.5 Inch 5 Inch Multipurpose Diamond Cutting Blade Reinforced Circular Diamond Saw Blade For Cutting Stone Concrete And Tile

-

4" 4.5" 5" 6" 7" 8" 9" 10" Slim Diamond Tile Saw Blades Tile Saw Blades For Cutting Tile Granite Marble

-

105mm 115mm 125mm 180mm 250mm hot press tile cutting turbo diamond disc saw blade for porcelain

-

SONGQI 4-4.5 Inch Multipurpose Diamond Cutting Disc Reinforced Round Diamond Saw Blade For Cutting Stone Concrete And Tile

-

1600mm 2000mm Large Circular Saw Blade Stone Cutting Diamond Saw Blade

-

Hot Sale 125mm Diamond Disc Mesh Turbo Diamond Saw Blades Concrete Granite Saw Blades Cutting Blades For Tile Marble

-

Professional wood band saw for wood mizer saw grinder blade

Other Products

-

$4.50 / piece

$4.50 / piece -

$5.00 / piece

$5.00 / piece