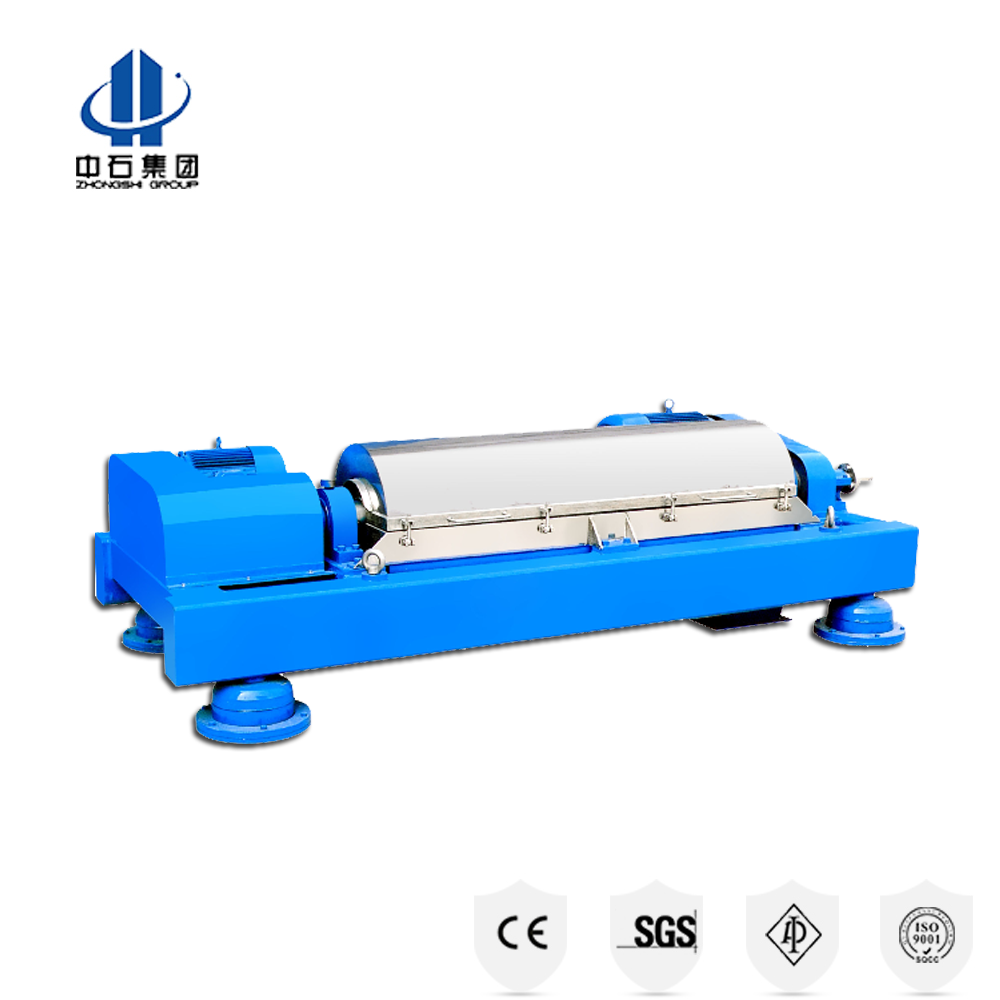

Good price!! Large capacity Price of high speed 2 or 3 phase decanter centrifuge for separating water from mud

-

Supplier: Puyang Zhongshi Group Co., Ltd. -

Region: Henan, China -

Contact: Ms Betty w -

Price: $25000.00 /piece -

Min. Order: 1 piece

Product details

| Marketing Type: | New Products 2020 | After-sales service provided: | Free spare parts, video technical support, online support |

| Packaging Preview: | color: | custom made | |

| Name: | Decanter centrifuge | strength: | 7.5 - 132 kW |

| Supply capacity: | 1000 acre decanters per month | weight: | 400 - 1300 kg |

| Local service location: | Philippines, Pakistan, Russia, Thailand, Malaysia | Warranty: | 1 year |

| payment terms: | letter of credit, wire transfer | model: | length and width |

| type: | Oilfield Centrifuge | Certification: | CE/ISO/API |

| Packaging Details: | Standard export packing for decanter centrifuge, with waterproof plywood or iron box or customized upon request | Core Components Warranty: | 1 year |

| Health status: | new, new | Voltage: | 110 - 415 Volts |

| Mechanical test report: | if | place of origin; place of origin: | Henan, China |

| Applicable industries: | Building Materials Stores, Manufacturing Plants, Mechanical Repair Shops, Food and Beverage Plants, Construction Engineering, Energy and Mining | Video external inspection: | if |

| Core components: | pump, bearing | size: | 1600*1100*850 |

| Showroom location: | Pakistan, Russia | port: | Qingdao/Tianjin/Shanghai/Guangzhou Port |

Product Description

Decanter Centrifuge|Drilling Mud Decanter|Oilfield Centrifuge- Zhongshi Solids Control

Zhongshi decanters are designed for drilling mud solids control and oilfield waste management. Zhongshi variable frequency drive decanter centrifuge with variable speed allows drilling contractors or mud service companies to perform barite recovery, fine/ultrafine solids separation, dewatering centrifuges. Zhongshi has a range of decanters from 9-inch to 22-inch bowls for different applications. The length to diameter ratio of the medium decanter centrifuge exceeds 3, which provides the best results for drilling fluid cleaning

Applications

Centrifuges are key equipment for handling harmful ultrafine solids in drilling fluids. It can separate and recover solids with a particle size larger than 5 μm, restore the density of drilling fluid, and improve drilling speed. It is an ideal drilling fluid purification equipment for drilling deep wells and horizontal wells. The equipment is mainly used to control the density and viscosity of the drilling fluid, reduce the solid content in the drilling fluid, remove harmful solids, recover barite, and recycle the bottom of the cyclone to ensure the excellent quality of the drilling fluid. performance, increasing drilling speed. .

Features of economical configuration decanter centrifuge:

Patented design, highest configuration and best material, long-term reliable service. Cylindrical and conical sections made of duplex stainless steel 2304 by centrifugal casting. Bowl assembly material for other parts: stainless steel SS304. Screw protection: Tungsten carbide tiles last longer and are easier to replace. Screw flow distribution port and drum solids discharge port protected by tungsten carbide alloy. Easy adjustment of liquid discharge weir height for flexible application. Bowl assembly supported by tensioning straps to protect bearings during movement. Pressurized explosion-proof VFD control cabinet with PLC control. Genuine SKF bearings for longer and more reliable operation

GLW450 Decanter Centrifuge (Barite Recovery)

The GLW450 Decanter is the most competitively priced centrifuge for barite recovery and separation of high gravity solids up to 5 microns. The GLW450 decanter has removable legs for use with solids control mud tanks or telescoping skids. The GLW450 Decanter has a bowl diameter of approximately 18" (450mm) and a bowl length of 43" (1100mm), the GLW450 Decanter consists of a large torch sun gear gearbox with a single motor. This design is designed to get the right result for the customer at the lowest production cost. Usually, the solid control system of large drilling rigs will install dual centrifuge systems, one

GLW450 medium speed centrifuge (G force 815 @1800 rpm) for barite recovery or high specific gravity solids separation, a high speed

GLW355 (G-force up to 2062 @3200RPM) centrifuge for low gravity fine solids separation. Also an affordable option

Underground works such as no excavation drills.

GLW450 medium speed centrifuge (G force 815 @1800 rpm) for barite recovery or high specific gravity solids separation, a high speed

GLW355 (G-force up to 2062 @3200RPM) centrifuge for low gravity fine solids separation. Also an affordable option

Underground works such as no excavation drills.

GLW355 Decanter Centrifuge (High Speed)

The GLW355 Decanter Centrifuge is the most popular size centrifuge in the oil drilling industry. Can be used for fine/ultrafine solids separation, barite recovery and zero-emission dewatering. With its removable legs, the GLW355 decanter can be used as a solids control mud tank or as a telescopic skid for drilling waste management. The GLW355 Decanter has a bowl diameter of approximately 14" (360mm) and a bowl length of 50" (1270mm), 3.5 is a good bowl length/diameter ratio for oil drilling mud. GLW355 decanter centrifuge is driven by main motor, rear drive motor adopts high torch Sun-Wheel gearbox, ZhongShi has different pulleys to choose fixed speed to change centrifuge speed, and VFD drive with PLC control is available for your different applications.

Product parameters

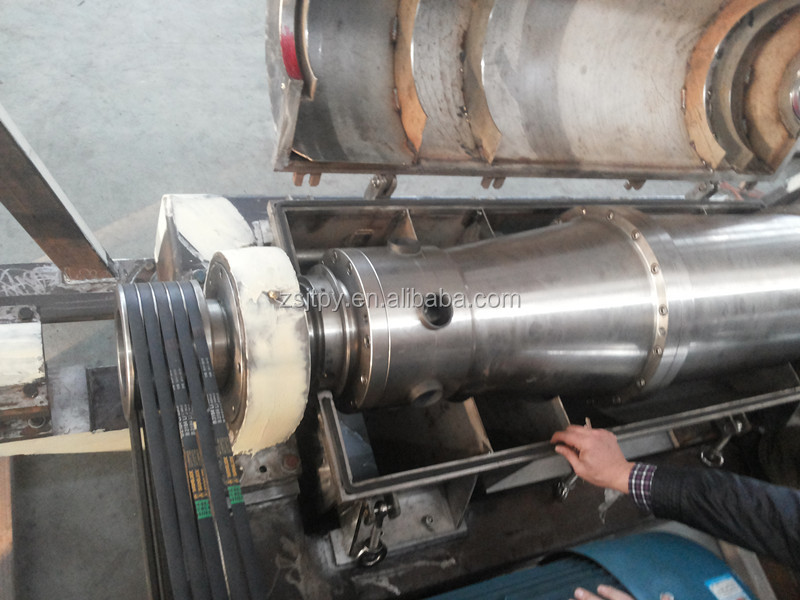

detailed picture

factory produced

customer photo

VIEW MORE

You may like

-

Squeeze tube filling and sealing machine lip gloss tube hand cream gel filling machine

-

Advanced Industrial Vacuum Emulsification Mixer Vacuum Homogenizer Emulsifier Cosmetic Lotion Foundation Making Machine

-

Laboratory cosmetics thick pressed flash eye shadow blush pressing machine pressed pigment eye shadow pressing machine

-

Chemical Equipment Mixer Sta Food Grade High Quality Jacketed Mixing Tank Stainless Steel Mixing Tank Cosmetic Mixer

-

100L vacuum emulsification homogeneous mixer steam or electric heating oil and water pot

-

SiLian factory 220v cosmetic eye shadow press machine for cosmetic products

-

200L Liquid Chemical Mixer Equipment Cream Homogenizer Soap Shampoo Making Mixing Tank With Agitator

-

20L traditional herbal essential oil distiller home-cooked gourd-shaped mini distiller essential oil extraction machine

-

Make-up powder compact high-gloss pressed powder eye shadow powder forming semi-automatic powder shaping machine

-

Heated Double Jacket Mixing Tank, Stainless Steel 304/316 Vacuum Agitator Liquid Soap Mixing Tank

Other Products

-

$150.00 / piece

$150.00 / piece -

$100.00 / piece

$100.00 / piece -

$13500.00 / set

$13500.00 / set -

$2500.00 / piece

$2500.00 / piece -

$450.00 / piece

$450.00 / piece -

$19.00 / piece

$19.00 / piece

Related Search

high speed paper cup machinery price

good price dry area of 2 sqm vacuum freeze dryer

price of crumb rubber

psa price of nitrogen gas

good price electric strapping machine

price of bevel gear

the price of evaporators

best price with high qualiti ku lnb suppliers

price of silicon carbide

price of push buttons switch