100L Small Cheese Barrel Cheese Maker

-

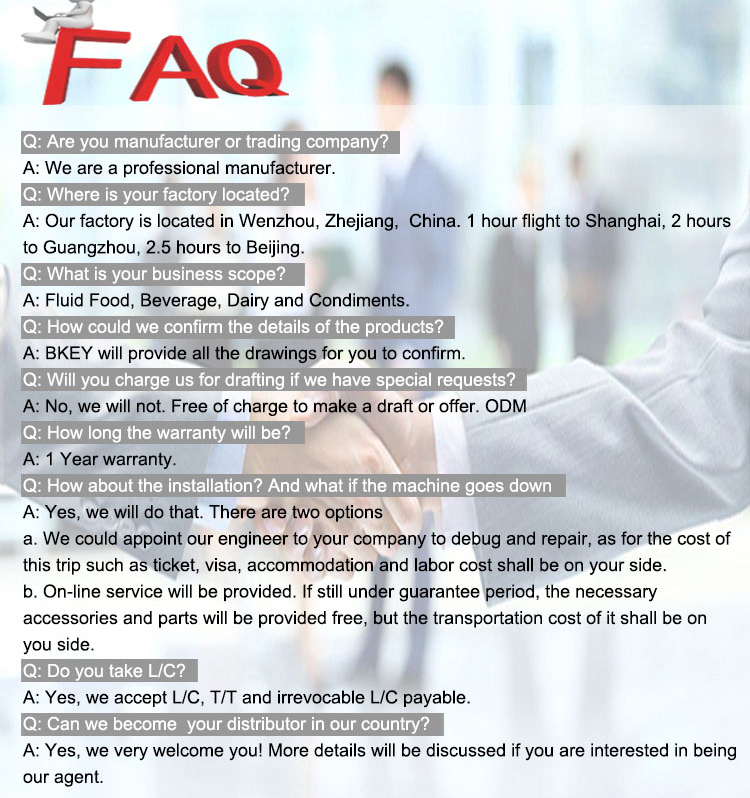

Supplier: Wenzhou Bkey Light Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Symon Xu -

Price: $2150.00 / 1 - 4 sets

$2100.00 / >=5 sets -

Min. Order: 1 set

| port: | Ningbo | strength: | 0.55W |

| weight: | 200kg | Dimensions (L*W*H): | based on capacity |

| Name: | cheese machine | Supply capacity: | 20 sets per month |

| Mechanical test report: | Not available | Core Components Warranty: | 1 year |

| application: | cheese making | Applicable industries: | Manufacturing Plants, Food and Beverage Plants, Farms, Restaurants, Retail, Food and Beverage Stores |

| Warranty: | 1 year | Finished goods: | cheese |

| After Warranty Service: | Online support | Showroom location: | not any |

| place of origin; place of origin: | Zhejiang, China | Health status: | new |

| brand: | key | heating method: | electrical |

| Material: | Stainless Steel 304 | Main selling point: | high productivity |

| capacity: | 100L | Voltage: | 380V/220V/custom |

| Processing power: | customer request | Blender Type: | custom made |

| Core components: | motor, fuel tank | Video external inspection: | Not available |

| Marketing Type: | Hot Products of 2019 | payment terms: | L/C,Western Union,T/T |

| Control Type: | automatic control | Packaging Details: | wooden box |

| Packaging Preview: |

100L Small Cheese Barrel Cheese Maker

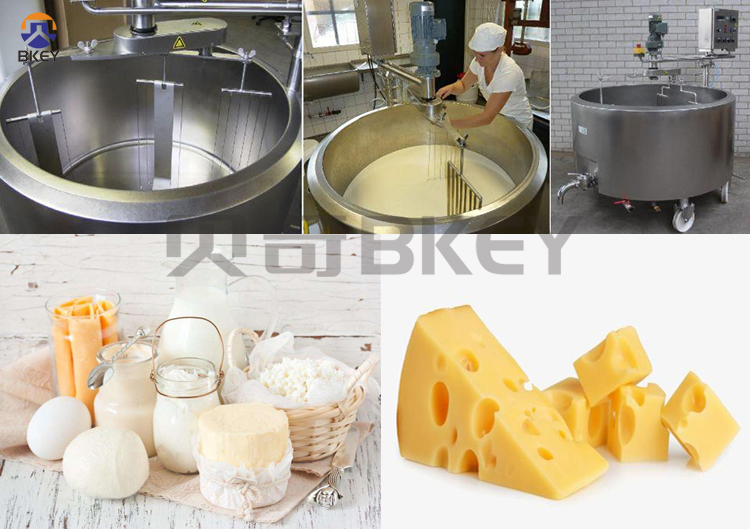

cheese bucketIt consists of main body, motor, stirring and cutting agitator, control box, etc. It can be used for ingredient mixing, milk coagulation, whey cutting, heating and cooling. The cheese milk is pretreated and mixed with rennet after adding a bacterial culture appropriate to the cheese type. The enzymatic activity of rennet causes milk to coagulate into a solid gel called coagulum. This is cut into small cubes of the desired size with a special cutting tool to facilitate the expulsion of the whey. During the rest of the curd-making process, bacteria grow and form lactic acid, and the curd particles are mechanically processed by a stirring tool, while the curd is heated according to a preset program. The combined effect of these three actions - bacterial growth, mechanical treatment and thermal treatment - results in syneresis, the separation of whey from the curd particles. The finished curd is placed into a cheese mould, which determines the shape of the finished cheese. The cheese is pressed by its own weight or by applying pressure to the mold. Finally, the cheese is coated, wrapped or packaged. Most types of cheese are aged for a period of time in the maturing chamber.

feature:

1. Capacity: round 100L-1000L/rectangular 600L-5000L

2. Three-layer structure (inner/heating/insulation)

3. Motor frequency conversion

4. Heating: Temperature range: 0-100℃, automatic temperature control

5. Blending: Two blenders for blending and cheese cutting

6. Insulation: keep the set temperature as needed

|

notes:Our style and capabilitiescheese machineVAT is all customizable. If you have any questions about our products, please feel free to contact us! |

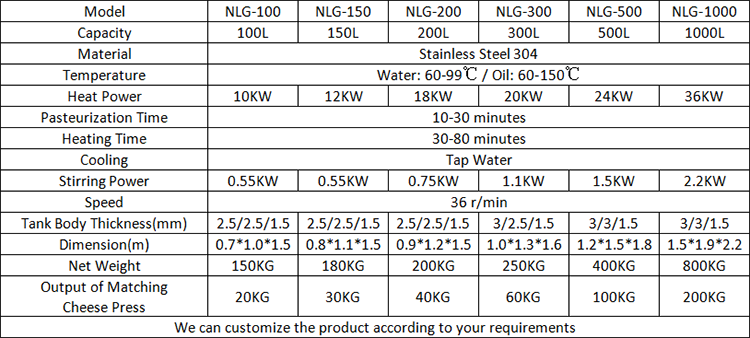

parameter:

-

500L 1000L 2000L cheese production line mozzarella cheese making machine cheese barrel

-

Stainless Steel Cheese Making Cooking Bucket with Double Whisk

-

Ice cream production line/ice cream machinery

-

Fully automatic electric 50/L stainless steel 304 centrifugal milk cream separator

-

Stainless steel 25L new milk mixer

-

Fully automatic continuous UHT milk production line, UHT milk processing plant

-

Fully automatic ice cream factory production line equipment rod extrusion sandwich bon bon ball cone extruder

-

Small mozzarella cheese production line mozzarella cheese making machine watt

-

Hot sale cheap 200 liters vertical 100 500 liters milk cooling tank price

-

milk jug, milk bucket, stainless steel jug

Other Products

-

$1250.00 - $1280.00 / set

$1250.00 - $1280.00 / set -

$1000.00 / set

$1000.00 / set -

$1800.00 / piece

$1800.00 / piece -

$2200.00 / set

$2200.00 / set -

$6000.00 / set

$6000.00 / set -

$1000.00 / set

$1000.00 / set