RICHI factory biomass wood pellet machine for sale

-

Supplier: Kaifeng Richi Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms RICHI GROUP -

Price: $7500.00 /set -

Min. Order: 1 set

Product details

| Bearings: | SKF | Applicable industries: | Manufacturing, Farms, Home Use, Construction, Energy & Mining, Power Plants |

| Core components: | Bearings, motors, gears, PLC, others, gearboxes | Processing raw materials: | Grass, rice husk, sawdust, biomass, straw, cotton stalk |

| Health status: | new | brand: | Hitachi |

| Motor power (Kw): | 90Kw | port: | Qingdao Port, Shanghai Port, Ningbo Port, Guangzhou Port |

| Core Components Warranty: | 2 years | Dimensions (L*W*H): | 2200*1500*2050MM |

| the size of granule: | 2-12mm can be customized | Power (kW): | 90Kw |

| Voltage: | 380V/415V/440V | Mechanical test report: | if |

| usage: | make bioparticles | spare parts: | Ring die + roller |

| application: | Power plants, boiler energy, combustion | Particle Diameter(mm): | 2 - 12 |

| Weight (kg): | 2000kg | motor: | Siemens brand |

| Video external inspection: | if | Warranty: | 2 years |

| Packaging Preview: | Supply capacity: | 300 wood pellet machines per month | |

| Raw materials: | Sawdust\straw\rice husk\sawdust\organic fertilizer | Main selling point: | long lasting |

| Packaging Details: | Standard international export packaging. The main biomass sawdust sawdust pellet machine unit is covered with plastic bags and packed in wooden boxes with steel frame structure. Spare parts will be protected in waterproof bags and boxes. All complete equipment will be packaged in 20''DP or 40''GP containers. | Output (kg/hour): | 1000 - 3000 kg/h |

| Name: | Granulator | Marketing Type: | other |

| capacity: | 1-10T/H | Material: | Stainless steel body |

| place of origin; place of origin: | Henan, China | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

Introduction of Granulator

How does a wood pellet machine work?

This pellet machine can make 3-6mm (specific size depends on the pellet size you need.) wood sawdust, straw, hay, rice husk, kernel and other biomass raw materials into biofuel pellets.The size of biomass pellets is usually 6/8/10/12mm, but we can customize any other size you need.

The principle is that when the raw material enters the granulation chamber, under the high pressure generated by the pressing roller, the raw material passes through the hole of the ring die, and then is cut by the cutter to form compacted biomass particles.

The principle is that when the raw material enters the granulation chamber, under the high pressure generated by the pressing roller, the raw material passes through the hole of the ring die, and then is cut by the cutter to form compacted biomass particles.

Raw materials and pellets

What raw materials can be used to make biomass pellets?

The RICHI biomass pellet machine can granulate a variety of biomass raw materials. Its diameter is generally 6/8/10/12mm, and the water content is 10-15%. Biomass particles come from a wide range of sources, and the common raw materials are:Forestry waste: Such as waste wood, waste branches, sawdust, etc.

Agricultural waste: Such as crop straw, rice husk, peanut shell, bagasse, palm kernel shell, etc.

construction rubbish:Such as waste paper, wooden frame, wooden template, etc.

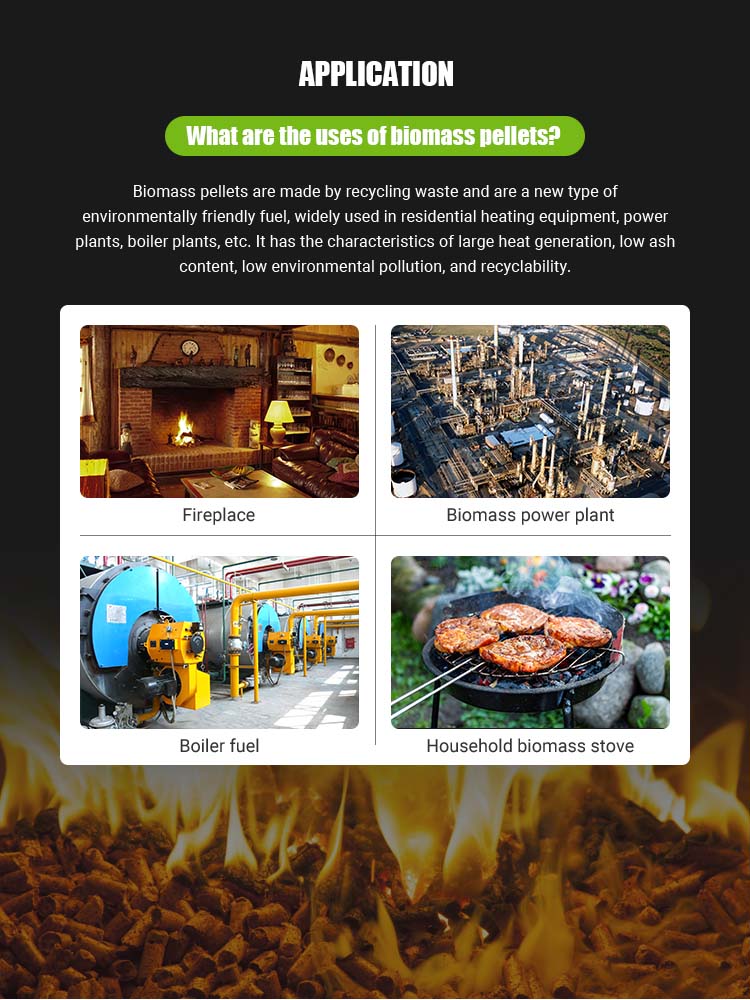

Application scenarios of biomass pellets:

Biomass pellets are made by recycling waste and are a new type of environmentally friendly fuel, which is widely used in residential heating equipment, power plants, boiler plants, etc.

Granulator Details

① SKF bearing ② Anti-caking device

③ Inverter ④ Siemens motor

⑤ Gear box ⑥ Pelletizing chamber⑦ Forced feeder ⑧ Raw material inspection port

⑨ Ring Die Hoist

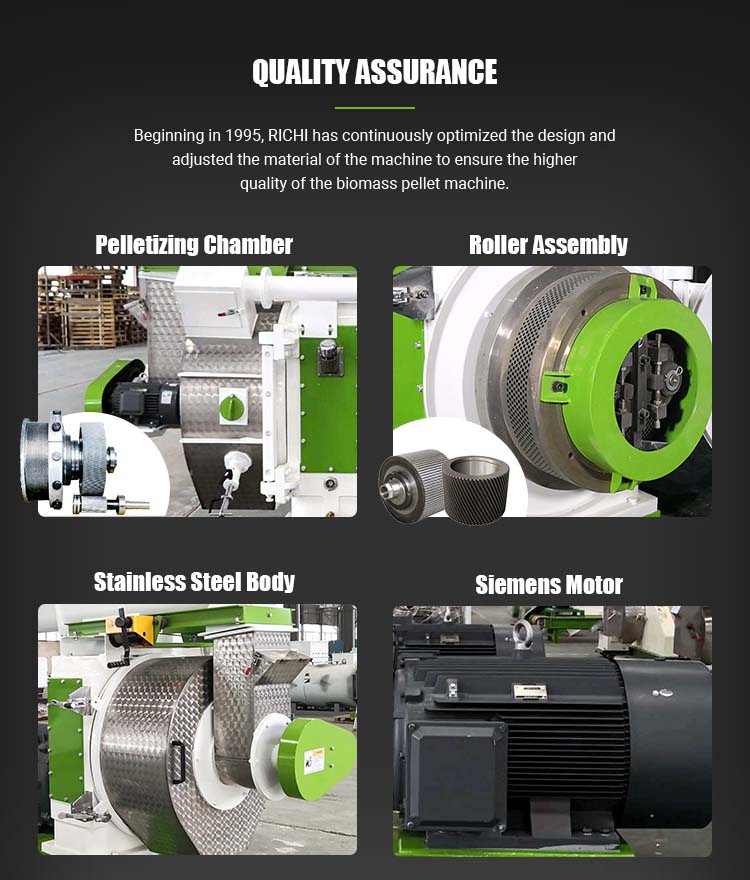

How does RICHI ensure the quality of biomass pellet machine?

Since 1995, RICHI has continuously optimized the design, adjusted the material of the machine, and ensured the higher quality of the biomass pellet machine.

Provide space for granulation. The main components are roller assemblies and ring dies, bearings, groove covers, etc.

The pelletizing chamber is equipped with a cutter adjustment handle, which can easily adjust the distance between the cutter and the ring die to control the length of the pellets.

With observation holes, you can observe the cutting condition of the particles by the cutter at any time, and master the production situation.

The pelletizing chamber is equipped with a cutter adjustment handle, which can easily adjust the distance between the cutter and the ring die to control the length of the pellets.

With observation holes, you can observe the cutting condition of the particles by the cutter at any time, and master the production situation.

▶Press Roller Assembly:

The roller assembly is made of 42CrMo material: compared with alloy materials such as stainless steel, it is more

Wear-resistant to ensure long-term stable operation of the machine.

Detachable Design: After working for a long time, just replace the pressure roller shell to repair the pressure roller assembly.

The roller assembly is made of 42CrMo material: compared with alloy materials such as stainless steel, it is more

Wear-resistant to ensure long-term stable operation of the machine.

Detachable Design: After working for a long time, just replace the pressure roller shell to repair the pressure roller assembly.

▶Stainless steel body:

The RICH biomass pellet machine adopts a stainless steel body to prevent corrosive substances such as moisture in the raw materials from corroding the pellet machine during long-term operation.

The RICH biomass pellet machine adopts a stainless steel body to prevent corrosive substances such as moisture in the raw materials from corroding the pellet machine during long-term operation.

▶Siemens motor:

The main motor of RICHI pellet machine adopts Siemens motor. The 8-level high-torque, high-quality and stable motor provides power guarantee for the long-term stable operation of the pellet mill.

The main motor of RICHI pellet machine adopts Siemens motor. The 8-level high-torque, high-quality and stable motor provides power guarantee for the long-term stable operation of the pellet mill.

What are the advantages of the ring die of the RICHI wood chipper?

The ring die is the core component of the pellet machine, and the quality of the ring die affects the life of the pellet machine.●The ring die of RICHI biomass pellet machine is made of 42CrMo material, which is more wear-resistant and durable than ordinary alloy steel or carbon steel ring die.

●The special surface carburizing treatment increases the surface hardness of the ring die and significantly increases the service life.

●Compression step-type demolding hole is adopted to ensure that the material enters the die hole smoothly.

●The high opening rate of the ring die ensures the continuous high output of the pellet machine.

How does RICHI ensure the efficiency of the biomass pellet machine?

▶Frequency conversion feeder:

The feeder is driven by a variable frequency motor, and the feeding speed is automatically adjusted by the inductive load voltage, which not only saves energy but also ensures the highest efficiency.

The feeder is driven by a variable frequency motor, and the feeding speed is automatically adjusted by the inductive load voltage, which not only saves energy but also ensures the highest efficiency.

▶Anti-cake device:

Prevent the formation of agglomerates that are not easy to fall into the feeder, and ensure the feeding efficiency.

Prevent the formation of agglomerates that are not easy to fall into the feeder, and ensure the feeding efficiency.

▶Force Feeder:

Located in front of the granulation chamber, the lighter raw materials can enter the granulation chamber smoothly and quickly to ensure the granulation efficiency.

Located in front of the granulation chamber, the lighter raw materials can enter the granulation chamber smoothly and quickly to ensure the granulation efficiency.

What is the humanized design of RICHI biomass pellet machine?

RICHI's rich manufacturing experience is reflected in some humanized design details:▶Material Chute:

RICHI designed an inclined opening in the chute above the granulation chamber. In this way, we can remove the sawdust sample from the opening at any time and observe its condition and moisture content.

RICHI designed an inclined opening in the chute above the granulation chamber. In this way, we can remove the sawdust sample from the opening at any time and observe its condition and moisture content.

▶gear drive:

It adopts efficient and stable gear transmission, which is easy to maintain and not easy to be damaged. Just change the machine oil regularly.

It adopts efficient and stable gear transmission, which is easy to maintain and not easy to be damaged. Just change the machine oil regularly.

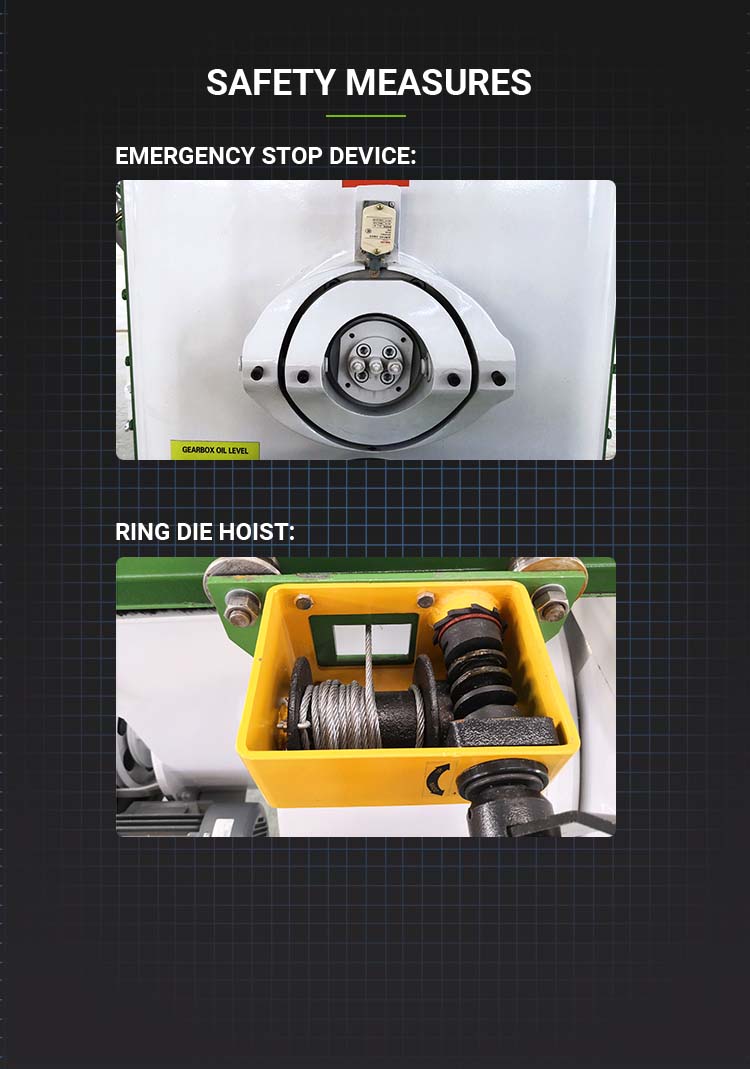

What are the safety measures of RICHI biomass pellet machine?

▶Emergency stop device:

Equipped with a safety pin design, when hard impurities such as metal in the pellet machine enter the pellet machine, the safety device is triggered to stop the pellet machine for protection.

Equipped with a safety pin design, when hard impurities such as metal in the pellet machine enter the pellet machine, the safety device is triggered to stop the pellet machine for protection.

▶Ring die hoist:

Used to assist in lifting the ring die when removing and replacing the ring die. Prevents such heavy ring dies from falling during replacement, injuring the operator or damaging the ring dies by falling.

Used to assist in lifting the ring die when removing and replacing the ring die. Prevents such heavy ring dies from falling during replacement, injuring the operator or damaging the ring dies by falling.

Granulator parameters

Model | Power (kW) | Capacity (tons/hour) | ||||||||

main motor | Anti-caking feeder | forced feeder | sawdust, etc. | grass, straw, etc. | Organic Fertilizer | |||||

MZLH-320 | twenty two | 1.5 | 0.55 | 0.3-0.5 tons/hour | 0.6-0.8 tons/hour | 1-2 tons/hour | ||||

MZLH-350 | 37 | 1.5 | 0.55 | 0.5-0.7 tons/hour | 0.8-1 ton/hour | 3-4 tons/hour | ||||

MZLH-420 | 90 | 1.5 | 0.55 | 1-1.5 tons/hour | 1.5-2 tons/hour | 5-6 tons/hour | ||||

MZLH-520 | 132 | 2.2 | 0.75 | 2-2.5 tons/hour | 3-4 tons/hour | 7-8 tons/hour | ||||

MZLH-768 | 250 | 3 | 1 | 2.5-4 tons/hour | 5-7 tons/hour | 9-10 tons/hour | ||||

MZLH-858 | 280 | 3 | 1 | 4-5 tons/hour | 8-10 tons/hour | 10-12 tons/hour | ||||

Engineering case

RICHI Wood Pelletizer in Poland Biomass Pellet Project.

The biomass pellet production line manufactured and installed by RICHI is located in Poland. Mainly used for the production of wood pellets and tire fiber pellets. The pellets will be used in fuel plants and sold directly on the market. It can produce 2-3T particles per hour.

RICHI wood pellet machine in Indonesia wood pellet production line project.

RICHI has manufactured several production lines in Indonesia which can produce up to 2T of wood pellets per hour. The main raw materials are sawdust, palm fiber, palm kernel shell, etc. Customers mainly use wood pellets for export and sale in the local market. The particle size is 6/8/10/12mm. We customize the particle size according to customer requirements.

find oneComplete wood pellet production line?

Please click on the products below for more information.

About Rich

Can I learn more about RICHI?

●Headquartered in Zhengzhou, Henan Province, Rich Machinery is an industrial group mainly focusing on biomass pellet machinery. It also involves strategic businesses such as feed pellet energy machinery, organic fertilizer pellet machinery, and spare parts.

●RICHI has a complete sales system and a complete sales service network, and its products are sold to more than 109 countries and regions nationwide and overseas. At present, the internationalization strategy is being implemented steadily, with 21 overseas agents and 1 overseas subsidiary in Uzbekistan.

●In the future, RICHI will always strive to improve its core technology and international competitiveness, and become a sustainable pellet machinery manufacturer.

●RICHI has a complete sales system and a complete sales service network, and its products are sold to more than 109 countries and regions nationwide and overseas. At present, the internationalization strategy is being implemented steadily, with 21 overseas agents and 1 overseas subsidiary in Uzbekistan.

●In the future, RICHI will always strive to improve its core technology and international competitiveness, and become a sustainable pellet machinery manufacturer.

What certificate does RICHI have?

With an unwavering commitment to quality, we introduce products with impeccable standards. We perform the production process using high quality materials and electrical advanced components. Our product range is parametrically tested to ensure longer service life and efficient performance. The company has passed the IS02008 quality management system certification, CE certification, etc.

VIEW MORE

You may like

-

China's leading manufacturer cheap biomass wood pellet machine high efficiency straw pellet machine

-

Industrial biofuel wheat and corn straw pellet machine, factory direct supply wheat straw pellet machine

-

Boiler pellet burner Wood pellet burner Canteen cooking machine Agricultural and sideline product water remover

-

pellet machine wood pellet machine for making pellets in winter in Eroup

-

Mini Sawdust Pellet Machine Animal Feed Chicken Poultry Feed Processing Machine Pulverizer Pellet Roller Machine

-

Charcoal large particle granulator

-

Hot Selling MKL335 Series Wood Pellet Machine

-

7.5kW flat die wood pellet machine flat die pellet machine wood pellet mill sawdust pelletizer

-

Wood Straw Rice Husk Pellet Making Machine

-

mobile wood sawdust pelleting machine/fertilizer pelletizer small feed pellet mill diesel engine