selective wave welding machine MF302 for welding plug-in components

-

Supplier: Beijing Glichn S&T Development Co., Ltd. -

Region: Beijing, China -

Contact: Ms karen peng -

Price: $1780.00 / 1 - 4 sets

$1380.00 / >=5 sets -

Min. Order: 1 set

| strength: | 1.2KW | After-sales service provided: | Engineers can repair machinery overseas |

| payment terms: | T/T,Western Union,MoneyGram,PAYPAL | Warranty: | 1 year |

| Voltage: | 220V | Applicable industries: | Manufacturing plant, electronic assembly production |

| Solder Pot: | Titanium Solder Bath | Welding time: | 1~12S adjustable |

| place of origin; place of origin: | Beijing China | brand: | Greenich |

| Selective wave soldering machine MF302: | The machine will be equipped with 3 nozzles of different sizes | Solder Capacity: | 30kg |

| Local service location: | U.S. | Packaging Preview: | |

| Showroom location: | U.S. | Supply capacity: | 60 sets per month |

| After Warranty Service: | Video technical support, online support | Preheat time: | about 30 minutes |

| weight: | 50KG | Dimensions (L*W*H): | 70*45*40cm |

| Packaging Details: | Export wooden packaging. | port: | Beijing/Tianjin/Shenzhen |

| Health status: | new | temperature range: | Room temperature--300°C |

| Certification: | CE/ROHS/CCC |

Selective wave soldering machine MF302, it is a multipurpose machine. Can be used for single-point soldering, removing IC and parts; special tool can replace the nozzle for various PCBs.

MF302 Features

1 MF302 automatic immersion tin design, which can be used for parts soldering and PCB after soldering;

2 The positioning is accurate, the tin immersion is uniform, the automatic operation is easier and the efficiency is higher.

3 MF302 can replace nozzles of any size; all kinds of PCBs can be welded by replacing nozzles;

4. Stepless adjustment, stable wave peak, reduce empty welding, side welding and other phenomena;

5 spot welding, low power consumption;

6 This machine has a compact structure and is widely used. The MF302 is easy to transport and saves space.

7 Titanium solder tank nozzle, solder suction mechanism is made of special alloy steel material (SUS316), lead-free soldering without corrosion and bursting problems. Minimum slag.

8 MF302 machines will be equipped with 3 different sizes of nozzles according to customer specifications.

9 daily preset timer (optional);

10 N2 protection system against pad and lead oxidation (optional);

11 MF302 infrared center positioning system to ensure more accurate soldering or taking components (optional);

energy source | AC 220V 50/60HZ 1PH |

Heater power | External heater, 1.2kw MF302 |

temperature range | Room temperature--300°C |

crest height | adjustable |

MF302 Welding time | 1~12S adjustable |

Preheat time | about 30 minutes |

Board size | MF302 600*380mm |

tin pan | Titanium Solder Bath |

timer | Automatic on/off timer for one week |

MF302 controller | PID mode, SSR driven |

safety protection | Short circuit protection, over temperature alarm |

MF302 Nozzle Material | Titanium alloy |

MF302 Solder Capacity | 30kg |

machine weight | 50kg |

Machine size | 70*45*40cm |

MF302 Nozzle Dimensions | 80*8mm, 80*10mm, 100*15mm, 150*10mm, 180*10mm, 200*23mm, 330×23mm or customized |

-

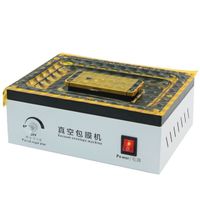

PCB board packaging vacuum packaging machine is simple to operate and simple to maintain.

-

Multifunctional Universal LED Bulb Assembly Equipment Fully Automatic LED Bulb Making Machine

-

Customized LCD Machine Accessories Glass Rod Quartz Rod

-

Magnetic powder brake

-

SE Series Arise actuators with various thrusts and shocks

-

Mobile Phone Jack Vacuum Coating Back Cover Film Envelope Machine for iPhone SAMSUNG Huawei Honor

-

Mobile phone hydrophobic nano liquid spraying machine

-

Pcb Drill Routing Cnc Machine Pcb Separator Cutting Machine Split Circuit Board Machine

-

85 inch Lcd Led Laptop Laser Screen Panel Repair Machine Laser Welding Solder Repair Machinery Bright Line Laser Repair

-

LED bulb machine light source board glue machine LED bulb machine electrical equipment