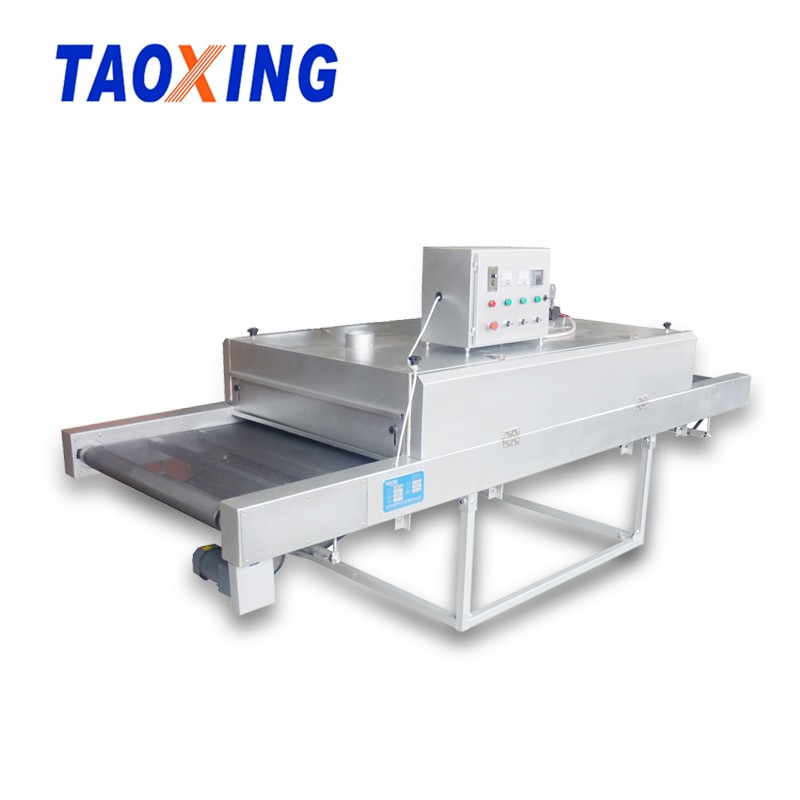

Hot Selling Screen Printing IR Drying Tunnel for T-Shirt Conveyor Drying Tunnel Tunnel Dryer for Gravure Printing

-

Supplier: Hangzhou Taoxing Printing Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Wayne Wang -

Price: $1033.00 /set -

Min. Order: 1 set

Product details

| product name: | IR drying tunnel for hot selling screen printed t-shirts | Mechanical test report: | Not available |

| port: | Ningbo or Shanghai | Main selling point: | easy to operate |

| Dry zone: | 4m (2 knots) | After-sales service provided: | Engineers can repair machinery overseas |

| type: | Dryer | Core components: | motor |

| Maximum temperature: | 150℃ | Showroom location: | France, Philippines, Mexico, Russia, Sri Lanka |

| color: | silver | Marketing Type: | New Products 2020 |

| Voltage: | 380V | payment terms: | Letter of Credit, Western Union, T/T, MoneyGram, PayPal |

| place of origin; place of origin: | Zhejiang, China | Belt width: | 600mm |

| weight: | 1200kg | Applicable industries: | manufacturing plant, printing plant |

| Packaging Details: | Each set of IR conveyor drying tunnel is packed in wooden case hot selling screen printing IR drying tunnel for t-shirt screen printing machine | Warranty: | 1 year |

| Dimensions (L*W*H): | 6000*800*1350mm | Supply capacity: | 50 Sets of Hot Selling Screen Printed T-Shirts IR Dry Tunnels per Month |

| brand: | peach star | Auto grade: | automatic |

| Video external inspection: | if | Health status: | new |

| After Warranty Service: | Video technical support | Core Components Warranty: | 1 year |

Product Description

ApplicationsIR drying tunnel for hot selling screen printed t-shirts

IR drying tunnel for hot selling screen printed t-shirtsIt is a fast drying solvent-based ink and a product containing moisture.

T-Shirt Hot Selling Screen Printing Infrared Tunnel Specifications | ||||||

Model | TX-IR60L | |||||

Machine size (L*W*H) | 6000*800*1350mm | |||||

Belt width | 600mm | |||||

input area | 0.5m | |||||

dry zone | 4m (2 knots) | |||||

cooling zone | 1m | |||||

output area | 0.5m | |||||

speed | 0~10m/min | |||||

maximum temperature | 150℃ | |||||

Heater lamp power | 20kW | |||||

Conveyor motor | 1.5kW | |||||

fan power | 2kW | |||||

all | 24kw (working: 12KW) 380V | |||||

main featureIR drying tunnel for hot selling screen printed t-shirts

1) The linear structure is simple and easy to install and maintain.

2) Pneumatic part, electrical part and operation part all adopt advanced world famous brand components.

3) The high pressure double crank controls the mold opening and closing.

4) Automatic, intelligent and pollution-free operation

5) Use the connector to connect with the air conveyor, which can be directly connected to the filling machine in series.

VIEW MORE

You may like

-

Manual UV Varnish Curing Machine

-

Double 100 Laminator Hot Laminator Hot Laminator

-

Portable UV curing machine 2Kw for process molding science experiment car UV paint repair

-

CBM-610 Paper Product Making Machine>> Spiral Notebook Binding Machine Inserter

-

KDC-100P hardcover book cover pressing machine

-

WY-650 Book Press

-

LED Uv Curing Machine Uva Flash Drying Lamp Unit Uv Lamp Curing Dryer For Screen Offset Digital Printer Varnish

-

Semi-automatic book cover rounding machine round edge banding machine

-

A3/A4 business card cutting machine, how to cut business card machine

-

New 16" X 16" Screen Printed Flash Dryer Adjustable Stand T-Shirt Curing with Temperature Display

Other Products

-

$120.00 / set

$120.00 / set -

$300.00 / set

$300.00 / set