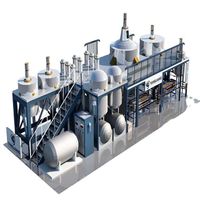

Rubber Plastic Tyre Pyrolysis Oil To Diesel Fuel Oil Distillation Plant

-

Supplier: Chongqing Vbolt Machinery Manufacturing Co., Ltd. -

Region: Chongqing, China -

Contact: Ms Bonnie Lei -

Price: $15500.00 /set -

Min. Order: 1 set

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | Type: | Membrane Distillation; |

| End product: | 80-93% Diesel; | Voltage: | 380V 50HZ 3P (Customizable); |

| Power consumption: | 8*10^5 kcal/h; | Showroom Location: | Egypt,Canada,Turkey,United Kingdom,United States,Italy,France,Germany,Viet Nam,Philippines,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,Mexico,Russia,Spain,Thailand,Morocco,Kenya,Argentina,Chile,UAE,Colombia,Algeria,Sri Lanka,Romania,Bangladesh,South Africa,Kazakhstan,Ukraine,Kyrgyzstan,Nigeria,Uzbekistan,Tajikistan,Malaysia,Australia,None; |

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; | Function: | base oil, diesel distillation tech; |

| Marketing Type: | New Product 2020; | Applicable Industries: | Manufacturing Plant,Energy & Mining; |

| Place of Origin: | Chongqing, China; | Name: | Rubber Plastic Tyre Pyrolysis Oil To Diesel Fuel Distillation Plant; |

| Warranty: | 2 years; | Supply Ability: | 100 Sets per Year; |

| Warranty of core components: | 3 years; | Power: | 380V.50HZ (Customizable ); |

| Raw material: | boiler steel , SS304, SS309; | Temperature: | -20-460℃; |

| Condition: | New; | Dimension(L*W*H): | Model Choose; |

| Package Preview: | ; | Packaging Detail: | nude package and wooden cases; |

| Video outgoing-inspection: | Provided; | Fuel supply: | any kind of fuel oil; |

| Port: | any port of China; | Weight: | 38000 kg; |

| Brand Name: | VBOLT; | Machinery Test Report: | Provided; |

| Fuel consumption: | 20-40kg/h; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Flow: | 700l/h; |

Rubber Plastic Tyre Pyrolysis Oil To Diesel Fuel Oil Distillation Plantnt

Chongqing Vbolt Machinery Manufacturing Co., Ltd manufactures and exports a wide range of used oil recycling plant, Pyrolysis oil recycling plant, lube oil refinery plant, solvent extraction system and oil purifier plant.

We also offer various Turnkey Project and Pipeline Fabrication Services. Our products are precisely designed by our team of expert professionals by utilizing their skills and vast knowledge in the product according to the demand. We on tend to use latest methodology to insure superior quality of our Products.

Step 1

Water and Light Fraction separation

Water content and light fraction separation is the first step in the VBOLT used lubricant oil recycling to base oil process. Used oils contains water and gasline which are oil-insoluble which easily separated by thin-film evaporator. Do not need one centrifuge only to remove the water content.

Step 2

Membrane distillation

Under high temperature, the used oil will form thin film in the membrane distillation kettle to increase the heating area and make the used oil vaporization, the used oil will become into oil gas quickly and efficiently, this step don’t have catalytic creaking into diesel molecules.

Step 3

Distillation with catalyst

The used oil gas coming from membrane distillation kettle will reacts with catalyst in the distillation column, the used oil molecular chain will break and recombine into diesel oil molecules. All steps with PLC automatic control system which can operate 24 hours per day.

Waste raw material:

Engine oil, motor oil, car oil

Ships oil, vessel oil

Lube oil, lubricant oil

Transformer oil, Turbine oils, Compressor oils

Hydraulic Oils (non -szntetic)

Gear Oils (non - fatty)

Machine oils (non - fatty)

Grinding oils (non - fatty)

Quenching oils (non -fatty)

Pyrolysis oil produced by tire or plastic

Specification

| Working capacity | 1000L/H |

| Fuel output range | 7*10^5Kcal/h |

| Fuel consume | 40-60kg/h |

| Fuel supply | Light diesel fuels/Kerosenen/Heavy fuel oil/Environmental oil/ Waste lube oil for burning(Molten salt furnace available) |

| Power | 50kw/h |

| Heating Method | Natural gas/Gasoil/Coal/Power |

| Oil Heat Temp. | (-10℃-460℃) |

| Voltage supply | 380v/50hz, 3 phase (customized according to local power supply is available) |

| Noise | ≤60dB |

| Dimension | 18*6*8M |

| Gross weight | 38T |

| Capacity supply | 100 liters/hour~2500 liters/hour |

Features

1). Our Systems are as small as 50 liters per Hour to as large as 2500 liters per Hour or higher, rated for 24 hours continuous operation for 330 days a year.

2). This plant have low maintenance cost, the time for maintenance is about one day each 30 days.

3). They are less expensive than most comparable types.

4). Our multistage systems can deal with a large variety of used oils. Such as: waste lube oil, engine oil, ship oil, and pyrolysis oil etc...

5). Our systems are PLC controlled and function automatically. Also can be customized for DCS system.

6). We offer Solvent Extraction to upgrade recovered diesel oil having low sulfur content and better color to get Euro 4 standard.

Pre-Sales Service

* We provide investment budget and manufacturing

* We provided product profit analysis, recommendation of machine and relevant budgeting, human resources allocation and budgeting.

* We provide the dimension of the equipment base, design of the equipment layout, workshop construction suggestion etc.

After-Sales Service

* One year guarantee for product quality. (People damaged parts are charged).

* Lifelong maintenance and spare parts supply.

* Free design of fixtures as customers required.

* Free training for machines installation and operation of the staffs at factory.

We have all reliable and complete certificates for equipment and company operations. And our oil treatment system patent certificate is unique in the industry, reflecting our company's high technology and strong practical ability.

Vbolt Machinery Manufacturer has been well known as a manufacturer to supply vacuum distillation plant, molecular distillation plant, pyrolysis oil distillation equipment and multifunctional oil purification machine in Chongqing city of China since the beginning of 2007.

In next years, the chief engineers team join hands with oversea mechanical engineers team to improve the traditional distillation technology to proprietary membrane distillation technology and further developed into Chongqing Vbolt Machinery Manufacturing Co., Ltd(name VBOLT) and set up own professional import and export team.

Up to now, we have obtained authoritative patents for membrane distillation technology, oil pyrolysis technology, oil purification technology. We own factory more than 5000 and more than 50 employees.

Being certified with ISO 9000:2000 and CE certificates, VBOLT researched VBT-DD advanced membrane distillation machine has been able to recycle used engine oil and other waste lubricant, tire pyrolysis oil and plastic pyrolysis oil into high quality diesel which can be used as fuel directly. It synthesized the advantages of traditional chemical treatment and distillation, and solved the problems as easy oxidizing and changing color. And it’s not as much cost as old generation molecular distillation.

So it’s proved as the lowest investment cost, faster return and energy efficient technology in the industry of used oil recycling. And it acquires a very high evaluation from Southeast Asia, Africa, South America, Europe etc.

All above information for your reference only, subject to our final confirmation. thanks!

-

Yangjiang waste oil refining equipment recycling waste motorcycle or automobile oil waste oil regeneration machine

-

Recycling waste oil into diesel oil refinery is highly profitable and low cost

-

China Made Heavy Fuel Oil Distillation Mini Refinery

-

Standard Diesel and Gasoline or Crude Distillation Units in U.S. Crude Oil Refinery

-

2023 NEW Oil filter machine Oil filter equipment manufacturing

-

New continuous oil filter oil recovery machine

-

Factory supply portable oil purifier hydraulic oil filter cart oil purifier unit

-

500kg/day small edible oil refiner crude oil refiner HJ-JLYJ200

-

Distillation Unit Price of Small Crude Oil Refinery

-

New energy TYR waste oil to diesel plant edible oil recovery machine oil filter machine

Other Products

-

$7000.00 - $7800.00 / set

$7000.00 - $7800.00 / set -

$15500.00 / set

$15500.00 / set -

$10000.00 / set

$10000.00 / set -

$17300.00 / set

$17300.00 / set