China 500ML Full Automatic 3 in1 Mini Small Business Scale Bottle Mineral Pure Drinking Water Filling Machine Price

-

Supplier: Zhangjiagang U Tech Machine Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Eileen Shao -

Price: $15000.00 / 1 - 19 sets

$9000.00 / >=20 sets -

Min. Order: 1 set

Product details

| Place of Origin: | Jiangsu, China; | Core Components: | Motor,Pump,PLC; |

| Marketing Type: | New Product 2020; | Driven Type: | Electric; |

| Packaging Type: | Bottles; | Supply Ability: | 20 Sets per Month bottle water filling machine; |

| Warranty: | 3 Years,3 years; | Automatic Grade: | Automatic; |

| Bottle size: | 500-2000ml; | Applicable Industries: | Manufacturing Plant,Food & Beverage Factory; |

| certification: | CE/SONCAP/ISO; | Weight: | 2000kg,2000 KG; |

| Warranty of core components: | 2 years; | Brand Name: | U TECH; |

| Package Preview: | ; | Packaging Detail: | standard wooden case for bottle water filling machine; |

| Packaging Material: | Wood; | Port: | Shanghai; |

| Dimension(L*W*H): | 3400*1670*2350mm; | Capacity: | 5000bph; |

| Key Selling Points: | High Productivity; | Voltage: | 220V 380V; |

| After-sales Service Provided: | Engineers available; | Material: | SUS304/316; |

| Filling Accuracy: | ±0.1; | Product name: | small scale bottle mineral pure drinking water filling machine; |

| Machinery Test Report: | Provided; | filling way: | gravity or micro pressure filling; |

| Payment Terms: | L/C,Western Union,T/T; | Video outgoing-inspection: | Provided; |

| Machinery Capacity: | 5000BPH; | Filling Material: | Water; |

| Type: | Filling Machine; | Showroom Location: | Canada,Turkey,United Kingdom,United States,Italy,France,Germany,Viet Nam,Philippines,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,Mexico,Russia,Spain,Thailand,Morocco,Kenya,Argentina,South Korea,Chile,UAE,Colombia,Algeria,Sri Lanka,Romania,Bangladesh,South Africa,Kazakhstan,Ukraine,Kyrgyzstan,Nigeria,Uzbekistan,Tajikistan,Japan,Malaysia,Australia; |

| Condition: | New; | Bottle type: | PET Plastic Bottle; |

| Application: | Beverage; |

Product Introduction

CGF series bottled water filling machine line is used to filling mineral water or purified water into PET bottle from 200ml-2000ml.Different models can satisfy various requirement of output from 2000BPH to 36000BPH.The machine combines washing,filling and capping three function in a body, the whole process is automatic, suitable for PET bottle, plastic bottle filling mineral water and pure water.Filling way using the gravity or micro pressure filling, make the speed is faster and more stable, so with the same model our machine output is higher and more efficient.The machine adopts advanced Mitsubishi programmable controller (PLC) to control the machine to run automatically, interworking with inverter running more stable and reliable.The photoelectric sensor detect all part running state, with high degree of automation, easy operation.

Bottle Sample

Technical Parameters

Model | CGF14-12-5 |

Capacity | 5000PBH |

Washing heads | 14 |

Filling heads | 12 |

Capping heads | 5 |

suitable bottle | PET bottle,plastic bottle |

Diameter of bottle | 55-110mm |

Height of bottle | 150-310mm |

Suitable cap | Plastic screw cap |

Weight | 2000kg |

Main motor power | 1.5kw |

Filling Machine Details

Washing heads

<1>All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

<2>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<3> 304/316 stainless steel washing pump

<2>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<3> 304/316 stainless steel washing pump

Filling heads

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

Capping heads

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during

capping

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

capping

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

Control System

S/N | Name | Brand | Country |

1 | Main motor | ABB | Switzerland |

2 | Inverter | MITSUBISHI | Japan |

3 | PLC | OMRON | Japan |

4 | Touch screen | MITSUBISHI | Japan |

5 | Contactor | SCHNEIDER | France |

6 | Thermo- relay | SCHNEIDER | France |

7 | Air-break switch | SCHNEIDER | France |

8 | Proximity switch | TURCK | USA |

9 | Photoelectric switch | BANNER | USA |

10 | Air circuit system | SMC | Japan |

11 | Water pump | Southern | China |

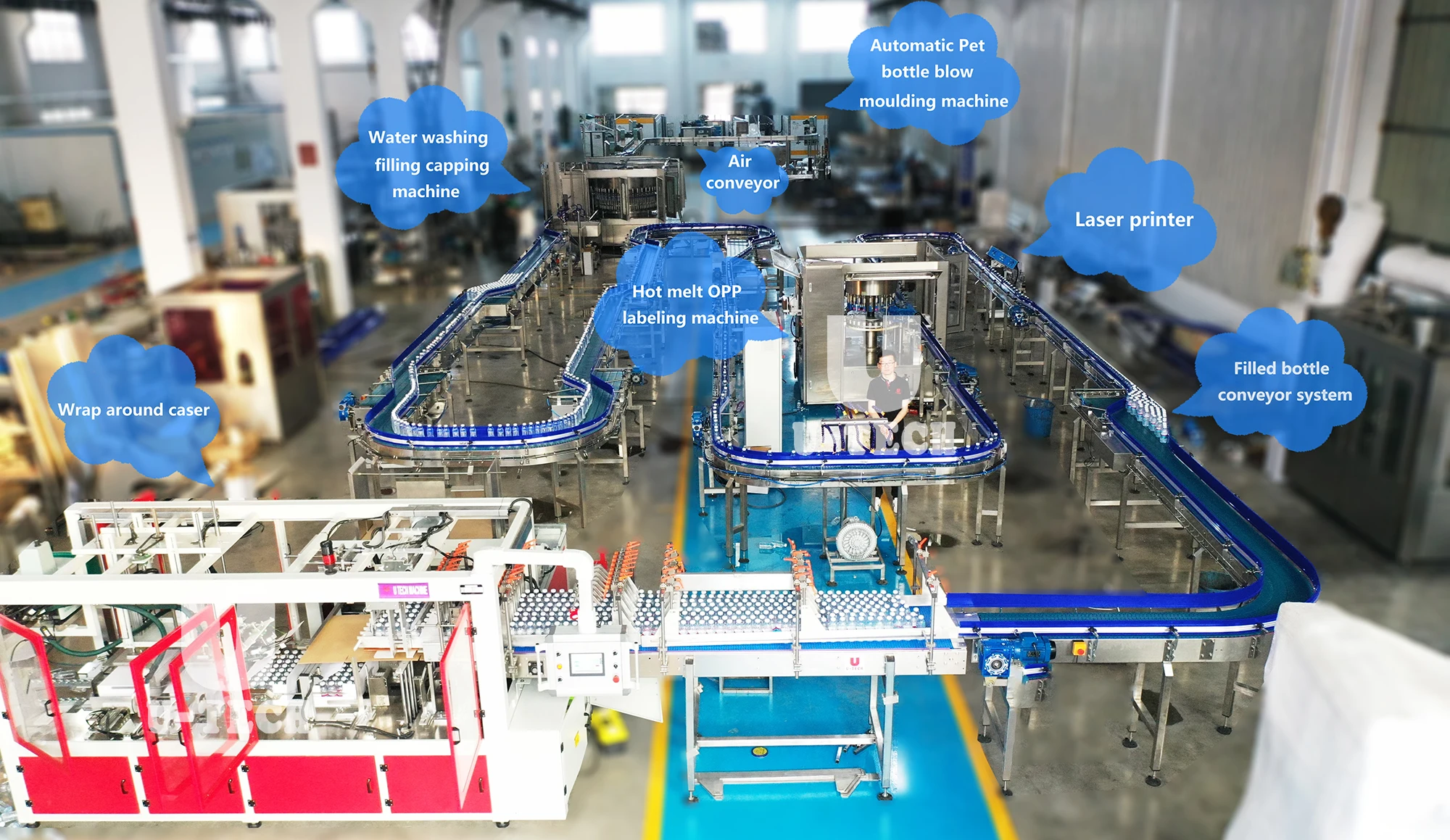

Production line flow

Water treatment system

The system is the process of purifying the raw water by a series equipments and devices to be drinkable.

Automatic PET bottle blow moulding machine

Suitable for blowing any kind of carbonated fruit juice beverage sparkling pure mineral water bottle.

Hot melt glue OPP labeling machine

This OPP labeling machine or hot melt adhesive labeler is suitable for labeling OPP material labels.

Laser printer

The pet bottle laser printer is suitable for cables PE pipes, automatic production line of date code or bar code.

Wrap around caser

The machine shapes the cartons automatically and closes their bottoms flaps within hot glue.

Related products

Cap injection molding machine

Semi-Automatic PET Bottle Blowing Machine

Sleeve labeling machine

Adhesive labeling machine

Shrink packing machine

Bottle dryer

Case erector

Case packer

Carton sealer

Machine Running Video

About U TECH

Certificate

Our service

Bottle layout design

Customize bottle shape according to customer's requirement

Plant design drawing

Help you to design plant and machine layout drawings

3 Years warranty

Free warranty for 3 years

FAQ

Q1:Do you have any reference project?

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Q3: Do you provide customized service?

>> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on.

Q4:When can I get my machine after I paid?

>> A4:We will deliver the machines on time as the date we agreed both side.

Q5:How can I install my machine when it arrives?

>> A5:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

VIEW MORE

You may like

-

Hot selling manual filling machine lotion bottle cosmetic filling machine shampoo paste honey piston paste detergent liquid filling machine

-

Machine for filling covers for washing animal bottles for sale

-

Fruit juice machine beverage filling line

-

Semi-automatic granule cup dosage filling machine small quantitative food granule packaging machine rice filling machine

-

Drinking water cup filling capping machine / water cup filling machine / water filling machine

-

Bag in Box Filling Machine for Fully-automatic Liquid Packaging

-

Fully automatic drinking pure mineral water bottle washing filling capping filling machine workshop production line

-

Automatic production of plastic bags drinking pure sachet pure water filling packaging machine

-

High quality liquid bottle filling machine made in China

-

HZPK automatic small milk drink water liquid detergent small bag filling and sealing machine

Other Products

-

$5500.00 / set

$5500.00 / set -

$25000.00 - $30000.00 / set

$25000.00 - $30000.00 / set -

$11000.00 / set

$11000.00 / set -

$12000.00 / set

$12000.00 / set

Related Search

small business pet bottle blowing machine

full automatic china tyre changer

full automatic egg incubator wq 1584

full automatic paper guillotine

full automatic crimping machine price

full automatic plastic blow molding machine suppliers

full automatic rice straw balers

egg incub is full automat suppliers

cafe full automat suppliers

full automatic tipping machine suppliers