Widely used corrugated industrial slitter knife paper cutter knife and spare parts

-

Supplier: Nanjing Licheng Machinery Blade Co., Ltd. -

Region: Anhui, China -

Contact: Mr wen tao -

Price: $20.00 / 10 - 49 pieces

$19.50 / >=50 pieces -

Min. Order: 10 pieces

Product details

| Packaging Detail: | Plastic + cardboard + wooden case; | Surface roughness: | Ra 0.2- Ra0.4 usually; |

| Brand Name: | LC; | Marketing Type: | Ordinary Product; |

| Warranty: | 3 months; | Condition: | New; |

| Dimension Tolerance: | OD±0.05mm, ID0.05-0.08 usually, Thickness ±0.01mm; | Video outgoing-inspection: | Provided; |

| After Warranty Service: | Online support; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; |

| Certificate: | ISO9001:2008; | Applications: | To slit corrugated paper; |

| Type: | slitting Knife; | OEM service: | Available; |

| Package Preview: | ; | Port: | SHANGHAI, BEIJING, SHENZHEN, GUANGZHOU; |

| Advantage: | Long Service Life; | Supply Ability: | 10000 Pieces per Month; |

| Merits: | High Wear Resistance; | Core Components: | precise & durable; |

| Material: | 9CrSi, SKD11, HSS, TCT; | Applicable Industries: | corrugated paper slitter,Wood industry,Metal industry,Plastic,rubber,film,foil,fiber glass; |

| Showroom Location: | None; | Warranty of core components: | 1 Year; |

| Hardness: | 59-66HRC 90HRA accordingly; | Machinery Test Report: | Provided; |

Products Description

Brand | LC | ||||||

Material | 9CrSi,SKD-11, HSS, TCT | ||||||

Hardness | 59-66HRC | ||||||

Precision | ±0.02mm | ||||||

Sharpness | 18N~30N | ||||||

Certification | ISO9001:2008 | ||||||

OEM Service | Available | ||||||

Applications | Paper industry. Wood industry. Metal industry. Plastic,rubber,film,foil,fiber glass cutting | ||||||

Advantages | 1. Stable quality with super fine grain size and high density 2. Strict tolerance control available for high requirements 3. Excellent wear resistance lasts 5 million meters 4. Superior strength of knife workable for high speed machine | ||||||

OD×ID×THK(mm) | Φ×Φ× | Φ×Φ× | Φ×Φ× | |||

Φ162×Φ102×1.2 | Φ230×Φ135×1.3 | Φ260×Φ114×1.4 | Φ265×Φ150×1.4 | |||

Φ180×Φ102×1.2 | Φ240×Φ32×1.2 | Φ260×Φ140×1.4 | Φ265×Φ170×1.4 | |||

Φ200×Φ122×1.2 | Φ240×Φ130×1.4 | Φ260×Φ150×1.4 | Φ265×Φ112×1.4 | |||

Φ200×Φ92×1.3 | Φ250×Φ105×1.4 | Φ260×Φ158×1.4 | Φ270×Φ168.3×1.4 | |||

Φ210×Φ122×1.2 | Φ250×Φ130×1.4 | Φ260×Φ160×1.4 | Φ270×Φ170×1.4 | |||

Φ230×Φ110×1.3 | Φ260×Φ105×1.4 | Φ260×Φ168.3×1.4 | Φ280×Φ168×1.4 | |||

Φ230×Φ130×1.3 | Φ260×Φ112×1.4 | Φ260×Φ170×1.4 | Φ300×Φ112×1.4 | |||

Company Profile

Manufacturing Technique

Step1 raw materia analysis and choice

Step2 Material forging

Step3 Raw material process

Step4 Material heat treatment

Step5 Product precise manufacturing

Step6 Product inspection

Step7 Product package

Exhibition

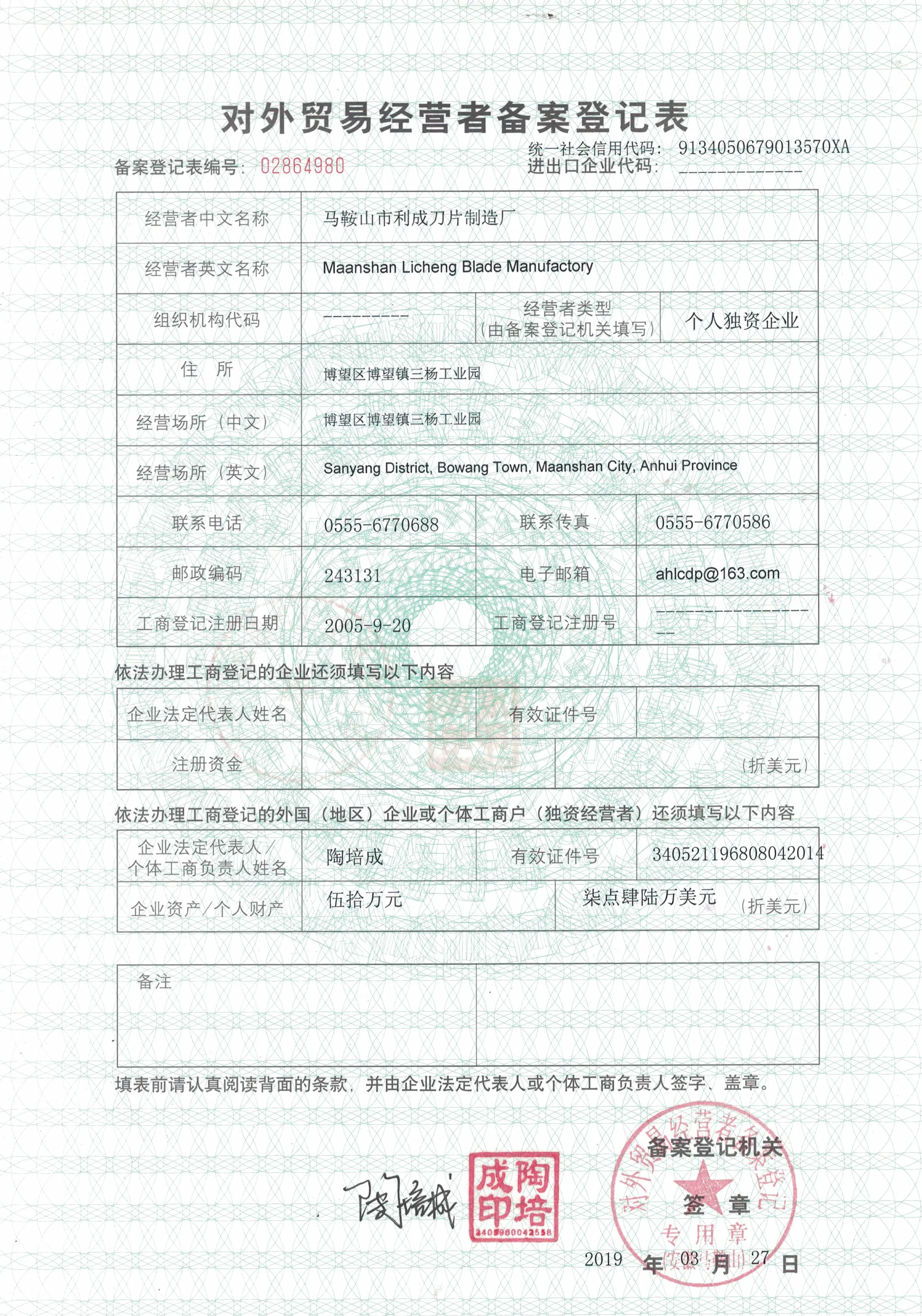

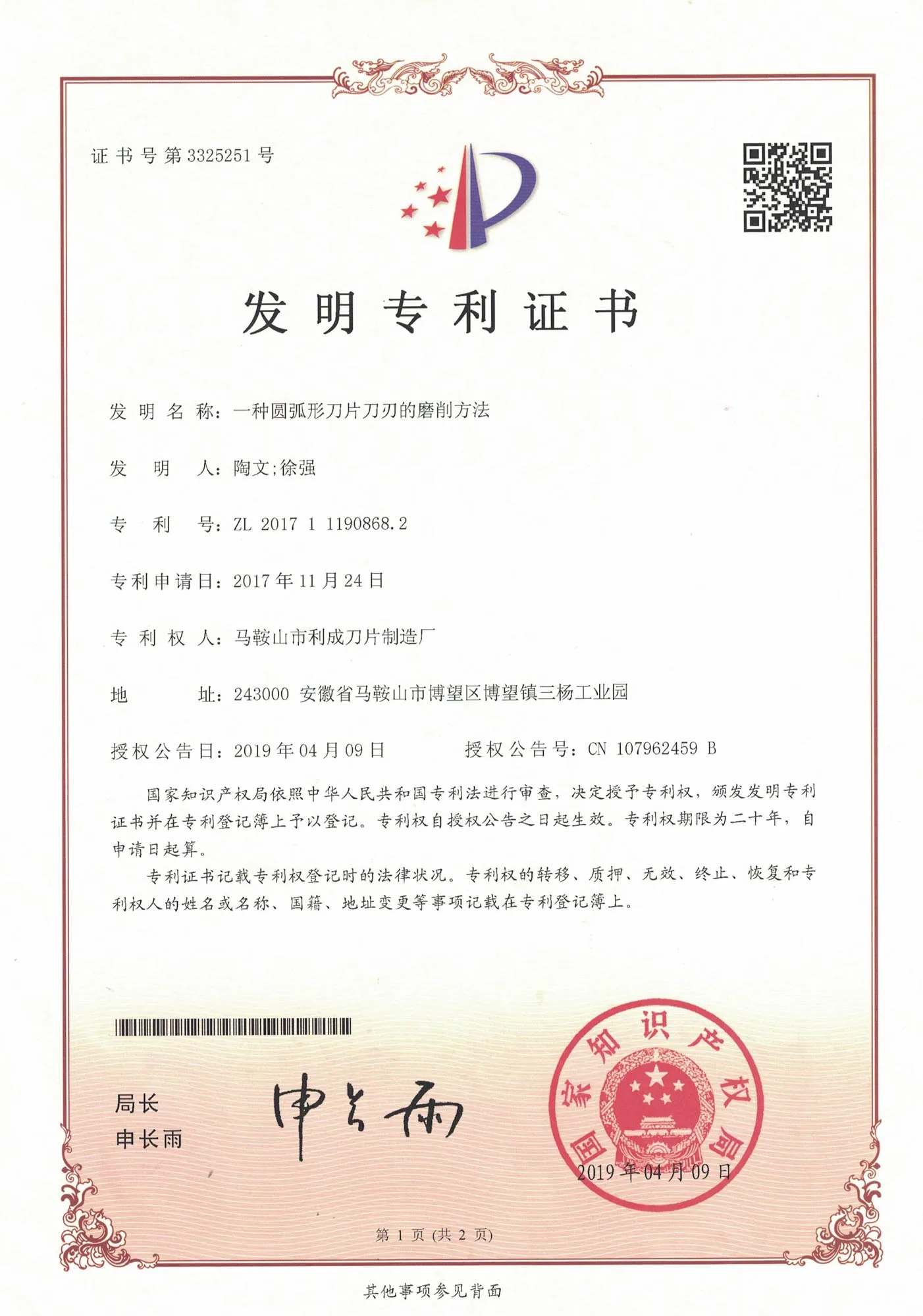

Certifications

Packing&Delivery

FAQ

1.Q: How to extend the life time of the corrugated paper knife?

A: 1. Match a suitable grain size of the grinding wheel.

Too coarse grain size of grinding wheel will shorten the life time of knifes.

2.Reduce the grinding frequency, grinding time and lower the grinding pressure.

2. The corrugated board is too wet.

Too coarse grain size of grinding wheel will shorten the life time of knifes.

2.Reduce the grinding frequency, grinding time and lower the grinding pressure.

2.Q: Why the edges of corrugated boards cut by knifes with burr and dent?

A: 1.The cutting edge of the blade is not keen enough.2. The corrugated board is too wet.

3.Q: Why there are chips on the cutting edge after grinding?

A: 1.Unstable swing grinding wheels may cause this problem, even break the knifes.

2.The strike of hard things may make the chips on the cutting edge.

2.The strike of hard things may make the chips on the cutting edge.

VIEW MORE

You may like

-

Serrated Knife Serrated Blades for Film Plastic Packaging Cutting

-

Circular Slitting Machine Metal Steel Slitting Blades for Rotary Metal Slitting Lines Rotary Slitting Machine for Metal Coil Production Industry

-

Durable CBN grinding wheel for resharpening thin paper cutting log saw blades

-

Customize different sizes of skd11 wear-resistant shredder blades plastic shredder blades

-

Cutting saw blade Cutting saw blade Cross cutting saw blade

-

Plastic Machinery Grinder Blade Hot Sale Knife

-

woodworking tools TCT circular saw blades for cutting wood

-

Light Duty Keyed Drill Chuck 0.6-6mm Range 3/8-24UNF Taper Mount Drill Chuck with 1/4 Hex Shank 3/8 Thread Extension

-

OEM SKD11 HRC57-58 High Hardness Crusher Blades Long Service Life Factory Direct Sales

-

Pulse Heating Blade Acf Bonding Head Knife Filter Cutting Blade for LCD Screen Repair

Other Products

-

$9.50 - $10.00 / piece

$9.50 - $10.00 / piece -

$9.50 - $10.00 / piece

$9.50 - $10.00 / piece -

$95.00 - $100.00 / piece

$95.00 - $100.00 / piece -

$45.00 - $50.00 / piece

$45.00 - $50.00 / piece -

$320.00 - $350.00 / piece

$320.00 - $350.00 / piece -

$65.00 - $70.00 / piece

$65.00 - $70.00 / piece -

$320.00 - $350.00 / set

$320.00 - $350.00 / set