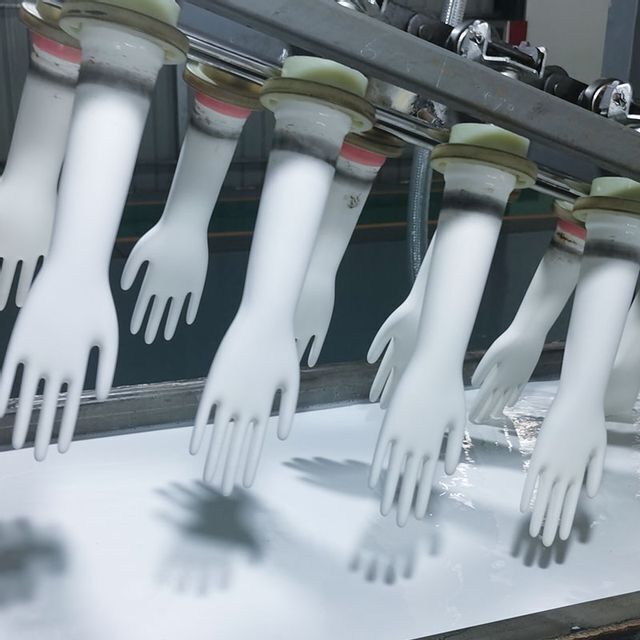

2020 Nitrile latex examination glove making machine production line

-

Supplier: Longkou Deyi Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Mr eason cheng -

Price: $450000.00 /set -

Min. Order: 1 set

| Function: | Working Gloves Maker; | Warranty: | 1 Year; |

| After Warranty Service: | Video technical support,No service,Online support,Spare parts,Field maintenance and repair service; | Marketing Type: | New Product 2020; |

| Package Preview: | ; | Feature: | Durability; |

| Video outgoing-inspection: | Provided; | Name: | Glove Making Machine; |

| power: | 15kw/h; | Supply Ability: | 1000 Set/Sets per Year; |

| Local Service Location: | None; | Machinery Test Report: | Provided; |

| Dimension(L*W*H): | 100*2*7.5m; | Heating method: | natural gas heating; |

| Voltage: | 380V; | Payment Terms: | L/C,T/T; |

| Port: | qingdao; | Showroom Location: | None; |

| natural gas: | 14400cubic meter; | Power: | 150000w; |

| Packaging Detail: | wood box packing; | Brand Name: | DEYI; |

| water: | 7-8t; | Production Capacity: | 4000-30000pcs/hr; |

| Color: | Blue; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service; |

| Core Components: | Motor,Gear; | Applicable Industries: | Manufacturing Plant; |

| Warranty of core components: | 1 Year; | Material: | Latex\Nitrile\NBR\PU\PVC; |

| Place of Origin: | China; | Control system: | PLC+Touch Screen; |

| Condition: | New; |

2020 Nitrile latex examination glove making machine production line

|

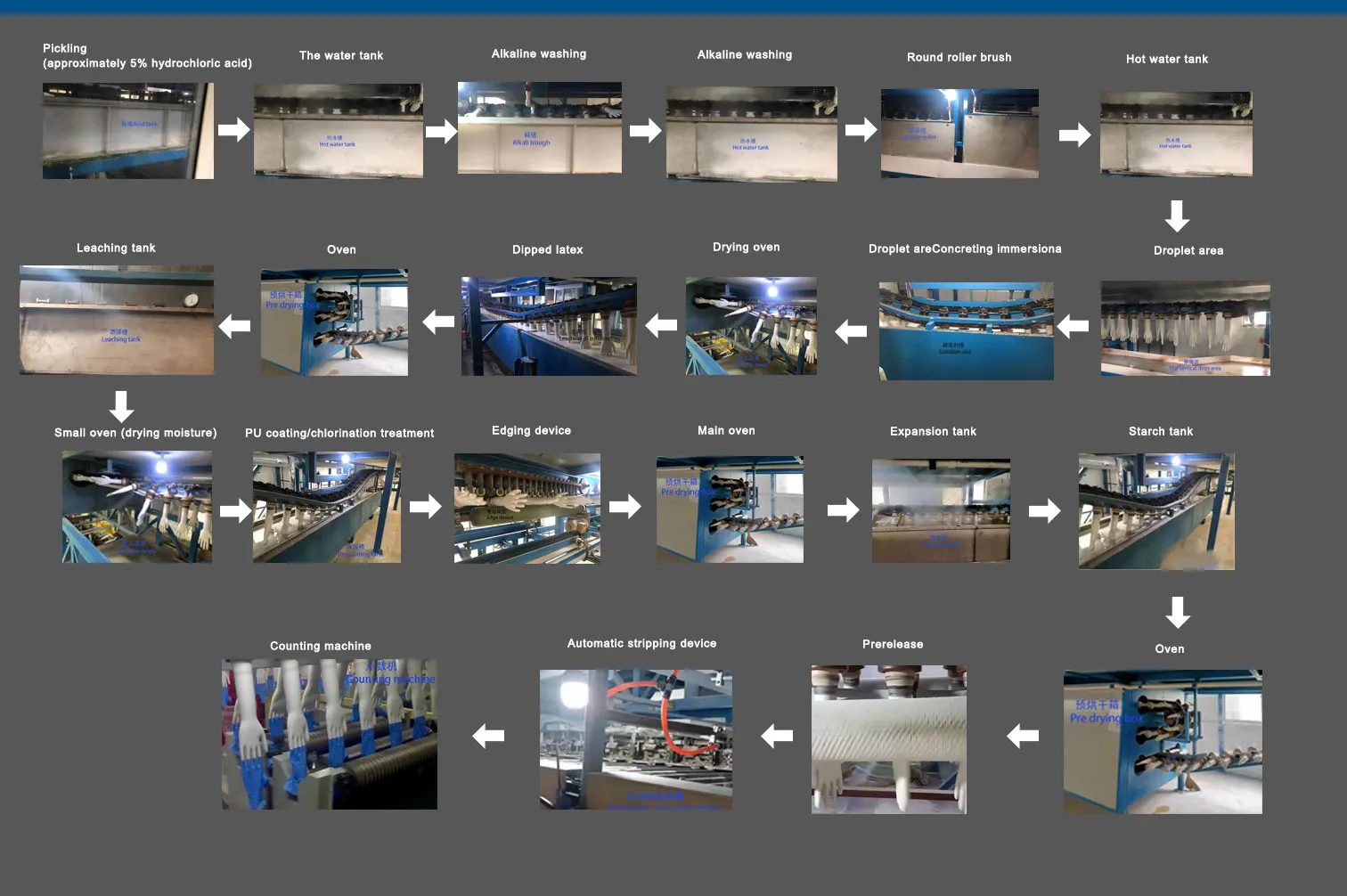

The nitrile/latex glove production line uses natural latex or synthetic rubber as the main raw material and other chemicals as auxiliary materials. The hand mold is cleaned with acid and alkali, and then cleaned with water again. Then the cleaned hand mold is first immersed in hot water and heated then immersed into coagulant and dried for dipping. After dipping, go into an oven for preliminary drying, flushed with hot water and then sent to another oven for curing and drying to form. After the gloves are demolded, they are inflated or filled with water for inspection, washed.centrifuged. and dried before packaging and sending them to the finished product warehouse.

|

|

|

|

|

|

1. The production line is non-standard customized equipment, which can be customized according to the length, width and height of the customer's workshop. The production line is divided into single mold and double mold. The advantage of single hand is more convenient to replace the hand mold, and the advantage of the dual mold is high output. |

|

2, latex/nitrile gloves production line can produce latex and nitrile gloves. When producing powder free gloves, nitrile gloves are chlorinated, while latex gloves can only be coated with PU coating. However, the effect of both powder free gloves is the same, which can prevent adhesion and make wearing smooth. |

|

3. If there are powder gloves, add talc powder or calcium carbonate and modified starch into the starch tank. If there are no powder gloves, add hot water. |

1. Adopt the most advanced gloves production technology and production process layout, product qualification rate is more than 98%, protein

content is lower than 120 micrograms per gram

2. TPU Coating technology

3. Imported surfactant solidifier, finished membrane is uniform, no powder mold release

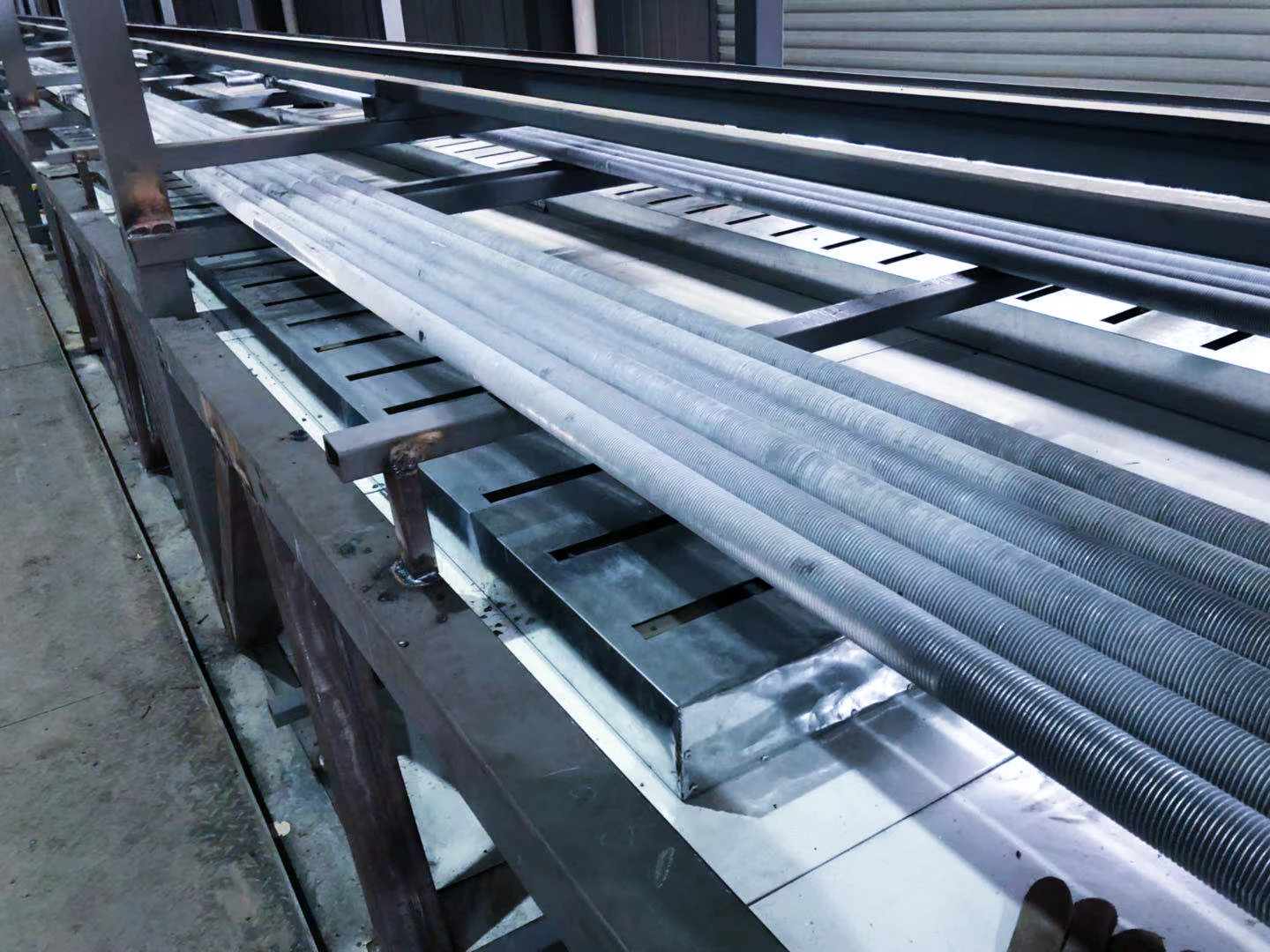

4. The introduction of foreign advanced transmission main chain structure, chain little resistance during operation, Production of high speed, stable operation

5. A main motor drag, solve the drag, difficult to synchronize, fault point, difficult maintenance, and other issues

6. Adopt vertical hot air circulation drying oven, compared with other forms of hot air circulation, save energy consumption by almost 20%

7. Used for cleaning mold splitter six roller long hair scrub mould technology

8. Mold directional, machine printing technology

9. A variety of specifications of production, on the same edge automatic adjustment, the PU edge roller, long service life

10. Can design according to the needs of customers of different length, height, cost models

1. DEYI COMPANY supports the client to pay by instalments.

2. All of accessories will be prepared at seller’s factory, the body of the production line can be bought from local market in order to cut client’s cost. It will take 90 days to prepare all accessories for the production line.

3. When all of parts have delivered to the client’s factory, we will arrange 2~3 engineers to guide the installation, there are of the 5-6 experienced mechanical workers from client’s side to help the installation. After finishing installation, 2 training engineers will take charge of workers’ train. The whole of process will spend 60 days on installation and train.

Q1:How Long Is The Warranty Period?

A1:one year,the after-sales is long life.

Q2: How About The Installation? Do You Have After-Sales Service?

A2: A:We will provide the installation video and manual.we also can send the professional technician to your company to install the machine and train your staff until they could operate the machine independently.

Q3: What Should We Prepare Except Material?

A3 You should prepare workshop, water line, electric line, compress air (if you need, we can help you buy air compressor). We can supply workshop layout drawing according to your workshop.

Q4: How long is the delivery time?

A4 the delivery time is 90days, the client can choose the installment

-

Latex/Nitrile Coated Gloves Dipping Production Line/Glove Coating Machine

-

Ultrasonic glove machine

-

Full Fashion Computerized Jacquard Gloves Making Machine GK2022 Price

-

Pons Roll Cutting Machine For Cotton Glove Making

-

Nitrile Gloves Production Line Disposable Hand Gloves Making Machine Latex Gloves Making Machine

-

Manufacturer Supplier Cotton Gloves Making Machine Making Gloves For Sale

-

Haisen computer glove knitting machine 7G

-

dot glove machine

-

2020 Fully Automatic High Speed 7G 10G Knitting Glove Machine

-

Work Gloves Knitting Machine Latex Gloves Making Machine

Other Products

-

$33000.00 / set

$33000.00 / set -

$26000.00 / set

$26000.00 / set