MY1B Series Double Acting Mechanically Jointed Pneumatic Rodless Cylinder

-

Supplier: Ningbo Fenghua Ningmao Pneumatic Components Factory -

Region: Zhejiang, China -

Contact: Ms Ning Mao -

Price: $53.40 /piece -

Min. Order: 1 piece

| Showroom Location: | None; | Supply Ability: | 1000 Piece/Pieces per Month; |

| Working medium: | Compressed Air; | Size: | M5X0.8,RC1/8/RC1/4; |

| After Warranty Service: | Video technical support,Online support; | Temperature: | -10~+70℃; |

| Payment Terms: | L/C,Western Union,T/T,Paypal; | Condition: | New; |

| Packaging Detail: | 1. Carton package 2. Pallet package 3. OEM packing is accepted; | Body Material: | Aluminum; |

| Standard or Nonstandard: | Standard; | Bore size: | 16/20/25/32/40/50mm; |

| Power: | Pneumatic; | Place of Origin: | China; |

| Warranty: | 6 months; | Machinery Test Report: | Not Available; |

| Marketing Type: | New Product 2020; | Local Service Location: | None; |

| Applicable Industries: | Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory; | Product name: | MY1B; |

| Stroke: | 1000mm; | Brand Name: | NMPC; |

| Warranty of core components: | 6 months; | Video outgoing-inspection: | Provided; |

| Port: | Ningbo or Shanghai; | Core Components: | Bearing,Pressure vessel; |

1.Classical design,durable ai control design

2.Energy saving and environmental protection with big low rate,safety and precision

3.Can work at the low pressure,smartness for on and off,good seal performance

4.Single action and double action types for your selection

5.Widely used in the food,machine,industry,abstention,Manufacturing,printing and other area

We Mainly do solenoid valve ,pneumatic valve, air treatment units, air Cylinder, quick connection fittings and PU tube .4V. 3V.2V.2p .solenoid valve ,and 4A.3A Pneumatic valve sell so hot in Asia, Europe,and Middle East.

Our products passed ISO9001:2008 and CE Quality Certification. Brand name is NMPC.

We have so many distributors and agent in mainland of China.

So popular in pneumatic and Hydraulic market. Our accessories taked from the same supplier as Airtac . O seal ring is Taiwan Xiehe,valve made by numerically controlled production center (CNC)

NINGBO FENGHUA NINGMAO PNEUMATIC COMPONENTS FACTORY

Professional production equipment

The factory has five production line,more than 100 workers . Cutting workshop make the brass raw material into appropriate length.after cutting some material send to Instrument lathe workshop and CNC workshop ,some of material send to punch workshop processed into the shape which we need. our CNC work shop Produces the product accuracy can be controlled in the error of 0.01 mm . And punch workshop can make goods according to your needed . The Assembly shop with automated equipment , Reduce the error of the product. PU tube workshop using European automation equipment,and clean management.

Rich processing experience

Our engineers team with rich experience in production line, an average of more than 10 years of experience in practice

Each year more than a month of study and communication It is our claim to the engineer.we have the modern warehouse management to ensure that the appropriate inventory to guarantee the delivery time, through the information management to reduce the warehouse cost, make products with competitive price.

Profession design team

We have our own product design team, and packaging design team.Help us to make the products fit your market , and help you win the market. we can make your logo on products and make the packaging with your logo or your design .

Rigid quality control

Every products we produce with strict inspection more than two times before packaging. We have a full set of inspection equipment,to do Pressure test and temperature test,some of products will do the durability test.To ensure every products with good quality .

-

Original 50M/roll, blue, pneumatic tube 558260 PUN-H-10 197386 PUN-H-10X1,5-BL FESTO plastic tube

-

Original FESTO pneumatic component valve 574429 VUVG-L18-M52-MT-G14-1P3 solenoid valve

-

Precision CNC Machining Stainless steel Machined turned Brass Pneumatic connection nuts

-

Digital Tire Inflator and Gauge with Valve Core Remover Air Chuck and Compressor Fittings Heavy Duty with Rubber Hose

-

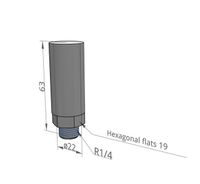

SMC Muffler AN200-02 SILENCER AN 2500, 2501, MUFFLER 1/4"PT *LQA

-

Pneumatic industrial brass connector quick connector air connector milton industrial brass air Quick coupling

-

Silencer of the AIRBEST ZSA series

-

Solenoid coil Valve coil Manufacturer 12V 24V DC 110V 220V 230V AC 12VDC 24VDC 24VAC 110VAC 220VAC DC24V AC220V 12 24 220 Volt

-

Hydraulic and Pneumatic Air Cylinders

-

MAL 20mm Bore 25-500 Stoke Single Rod Double Action Aluminum Alloy Small Spring Pneumatic Air Cylinder

Other Products

-

$16.00 / unit

$16.00 / unit -

$2.60 / piece

$2.60 / piece -

$2.30 / piece

$2.30 / piece