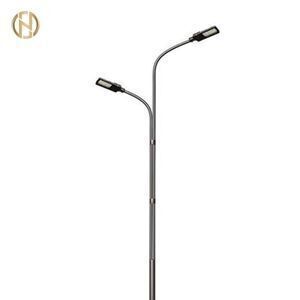

Galvanized 3-12M Single/Double Arm Q235 Steel Street Lighting Pole

-

Supplier: Yixing Futao Metal Structural Unit Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms emily li -

Price: $50.00 /piece -

Min. Order: 1 piece

| Surface treatment: | Hot dip galvanized; | Payment Terms: | L/C,D/P,D/A,T/T; |

| Model Number: | FT-TP037; | Package Preview: | ; |

| Height: | 3-60M; | Material: | Hot roll galvanizing; |

| Quality Control: | ISO9001:2000; | Brand Name: | FUTAO; |

| Color: | sliver; | Packaging Detail: | Our round galvanized metal tubular power steel electric pole as normal are covered by Mat or straw bale at the top and bottom and woods between the poles can avoid the damage of the galvanization on the surface of steel poles, anyway also we canfollow clients required , The loading capacity of 40HC or OT will be calculated basing on the clients' actual specification and data.; |

| Application: | Highway;airport;road; | Supply Ability: | 3000 Set/Sets per Month; |

| Thickness: | 2.5-20mm; | Name: | 3-12M Steel Street Lighting Pole; |

| Type: | Round or octangon; | Port: | Shanghai; |

| Place of Origin: | Jiangsu China; | Wind speed: | 160 Km/h; |

| Powder coated: | White;blue;silver;grey; |

Galvanized 3-12M Single/Double Arm Q235 Steel Street Lighting Pole

|

Height |

From 3 m to 25 m |

|

Suit for |

Airport ,seaport,plaza,stadium ,square,highway,street way etc |

|

Shape |

Conoid ,Multi-pyramidal,Columniform,polygonal or conical |

|

Material |

Usually Q345B/A572, Q235B/A36,As well as Hot rolled coil from Q460 ,ASTM573 GR65, GR50 ,SS400, SS490, to ST52- |

|

Lamp power |

20 W- 400 W (HPS/MH) 220V (+-10%) /50Hz |

|

Torlance of the dimenstion |

+- 2% |

|

Optical assembly of lighting fixture |

IP 65 |

|

Electroshock resistant protective grade |

Grade one |

|

The casing anti-corrosion performance |

Class two |

|

Working atmosphere of lighting fixture |

-35 °C~+45 °C |

|

Surface treatment |

Hot dip galvanized Following ASTM A 123, color polyester power or any other standard by client required. |

|

Joint of Poles |

Insert mode,innerflange mode,face to face joint mode |

|

Design of pole |

Against earthquake of 8 grade |

|

Wind Speed |

160 Km/Hour |

|

Minimum yield strength |

355 mpa |

|

Minimum ultimate tensile strength |

490 mpa |

|

Max ultimate tensile strength |

620 mpa |

|

Standard |

ISO 9001 |

|

Length of per section |

Within 12m once forming without slip joint |

|

Welding |

We has past flaw testing.Internal and external double welding makes the welding beautiful in shape Welding Standard :AWS ( American Welding Society ) D 1.1 |

|

Thickness |

1 mm to 30 mm |

|

Production Process |

Rew material test → Cuttingj →Molding or bending →Welidng (longitudinal )→Dimension verify →Flange welding →Hole drilling →Calibration → Deburr→Galvanization or powder coating ,painting →Recalibration →Thread →Packages |

|

Packages |

Our poles as normal cover by Mat or straw bale at the top and bottom ,anyway also can following by client required , each 40HC or OT can loading how many pcs will calculation base on the client actually specification and data.

|

|

Style |

Size and styles are veriable as per customer request |

-

Nickel plated carbon steel nut copper bus bar suitable for Toyota Camry 2007-2011 2012-2017 Lexus ES300h 2012-2017 hybrid car battery

-

Custom outdoor plastic case, waterproof plastic case for PC supplied from China

-

New safe portable waterproof and dustproof plug socket white distribution box industrial socket box with bracket

-

Power Supply Outdoor Enclosure Consumer Unit Electrical Distribution Box Stage

-

Best Selling Stage Light Plug Distribution Box Portable Distribution Box Industrial Socket Stage Power Supply

-

19" 2U Rack Mount Power Distribution Metal Box with Voltmeter

-

Twist Lock 30amp Inlet Power Distribution Rack Switchboard Box

-

Hot Sale Ip67 4 Way Plastic Window Cover

-

US Power Connector 110v Portable Electric Box

-

Dual power automatic transfer switch 63A 4P home generator switch complete set of distribution box distribution cabinet