Quality assurance graphite spiral wound gasket with inner ring and outer Customized Hot Sell 150 Ss316 Spiral Wound Gasket

-

Supplier: Langfang Fangdun Fireproof Sealing Material Co., Ltd. -

Region: Hebei, China -

Contact: Mr Qinghe Wang -

Price: $1.00 / >=50 pieces -

Min. Order: 50 pieces

| flat face washer: | metal cock and ball rings; | Packaging Detail: | cartons or as your request; |

| Supply Ability: | 500000 Piece/Pieces per Week; | Service: | 24 Hours; |

| Application: | Sealing Material; | Brand Name: | Fangdun; |

| Port: | Tianjin/Shanghai; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Standard or Nonstandard: | Standard; | Model Number: | Graphite Gasket; |

| Quality: | High-Quality; | Density g/cm3: | 1; |

| Place of Origin: | Hebei China; |

Customized Hot Sell 150 Ss316 Spiral Wound Gasket

Different specifications have different prices

Please consult customers for specific prices

Product Description:

Product Description:

Spiral Wound Gaskets are winding by "V" shaped metallic strip and soft non-metallic filler.

According to the requestment, the gaskets can be within inner and outer rings for improving the gaskets handling, fitting and versatility.

Depend on its excellent compresion resilience, it's suitable for sealing spots where the alteration of temperature and pressure are frequenty.

Basic Type:

Basic type gasket: inner and outer diameters are reinforced with several piles of metal without filler to give greater stability and better compression characteristics.

Suitable for tongue and groove, male and famale or grooved to flat face flange essemblies.

Inner Ring Type:

Solid inner metal ring acts as a compression stopper. To prevent accumulation of solids, reduce trubulent flow of process fluids and minimize erosion, damages of gasket between flange bore and the inside diameter, the annular space is filled up by solid inner metal ring;

Suitable for male and female pipe flanges.

Outer Ring Type:

Solid outer accurately locates the gasket on the flange face to give the additional radial strength to prevent gasket blowout and acts as a compression limiter. In case of installing the outer ring, it is very easy to install the gasket to flange face because the end of outer ring will touch at bolts;

Suitable for use with flat face and raised face flanges. For class 900 and above an internal ring is recommended.

Inner & Outer Ring Type:

An inner ring and outer ring type gasket will give an additional compression limiting stopper for gasket inner and outer side. It will prevent the corrosions on flange face at annular space;

Suitable for use with flat face and raised face flanges and specified for high pressure and temperature service, Class 900 and above or where corrosive or toxic media are present.

|

Metal Winding & Inner Ring |

Filler Materials |

Outer Ring Materials |

|

As Standard SS304(L) Others Stainless Steel 309 310 317L 321 347 Alloy 20 Monel 400 Titanium 1,2,7 Nickel 200 Inconel 600,635 Incoloy 800,825 Hastelloy B2 C276 Duplex 31803 Copper Inner ring: Carbon steel also abailable |

Flexible graphite PTFE Mica Ceramic Non-asbestos |

As Standard Carbon Steel others 304(L) 316(L) 317 310 321 347 410 Alloy 20 Monel 400 Titanium 1,2,7 Nickel 200 Inconel 600,635 Incoloy 800,825 Hastelloy B2 C276 Duplex 31803 |

If you are interested, click here to cantact me.

-

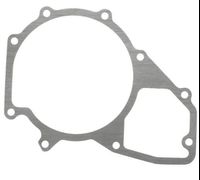

High quality water pump gasket 4032011080 4422010080 Mercedes truck engine gasket

-

Longcheng silicone gasket flat rubber China OEM non-standard custom waterproof molded 180 degrees 100 high quality

-

2022 hot sale heat induction sealing aluminum foil diameter 28mm/63mm PET

-

200 pc Copper Washer Gasket Nut and Bolt Set Ring Seal Assortment Kit with Oil Sump Plug Box

-

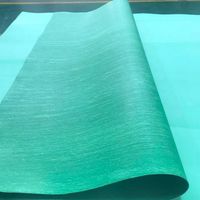

High quality XB150 high temperature resistant gaskets without asbestos rubber sheets

-

Asbestos-free rubber gaskets for compressors, pipes

-

High quality copper flat gasket, metal ring gasket, copper sealing gasket

-

Made in China No Asbestos Rubber Gasket Klingersil Gasket Design Custom Wholesale Pipe Flange Gasket

-

High quality teflon gasket custom EPDM gasket silicone gasket

-

Best Selling High Pressure Compression Gasket Asbestos Free Fire Resistant Fiberboard Asbestos Free Rubber Sheet

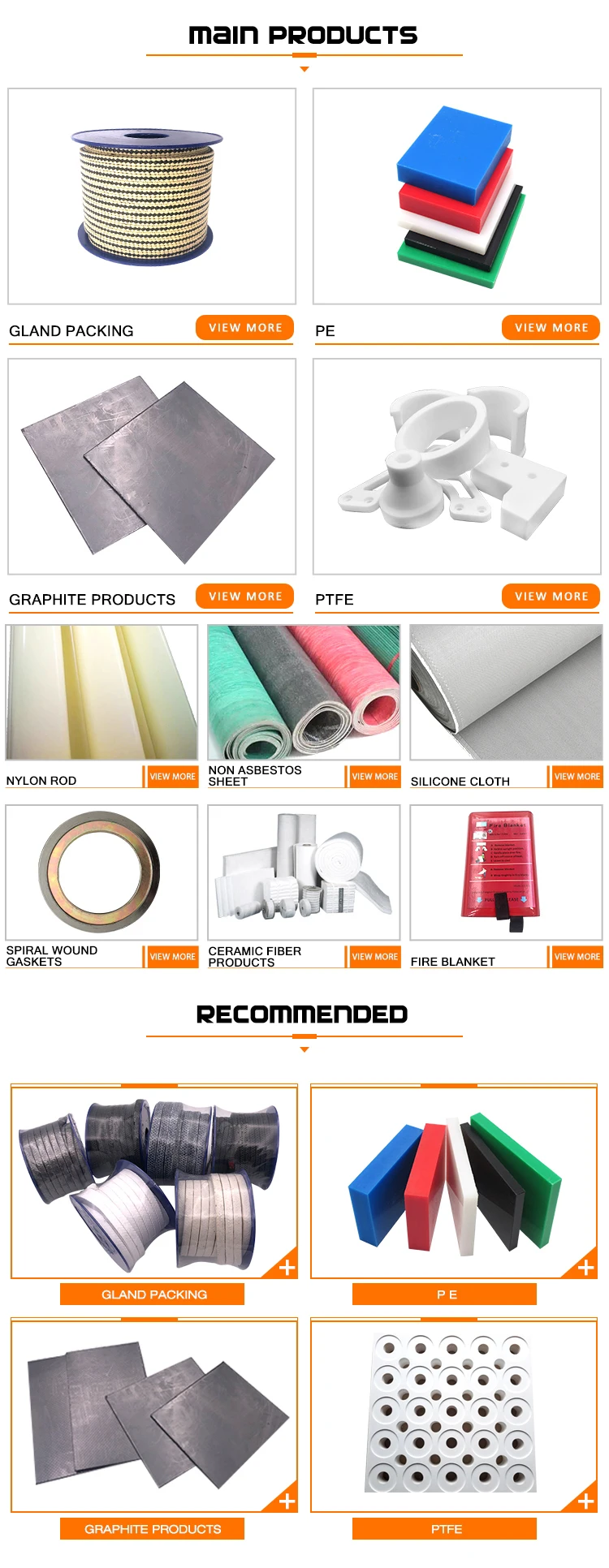

Other Products

-

$1.00 / kilogram

$1.00 / kilogram -

$0.10 / piece

$0.10 / piece -

$0.10 / piece

$0.10 / piece