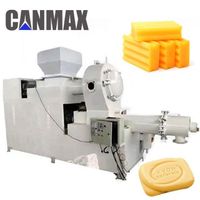

High quality Industrial Commercial Soap Bar Machine automatic mixing machine for soap

-

Supplier: Zhengzhou Bainte Machinery Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms Linda Cheng -

Price: $10.00 /set -

Min. Order: 1 set

| Function: | Automatic Production Line; | Port: | qingdao,tijin,shanghai; |

| Material: | Stainless Steel; | Type: | Travel Soap Production Line; |

| Product Type: | Soap; | Machine Type: | Soap Making Machine; |

| Usage: | Laundry Soap Stamping Machine; | Brand Name: | BNT; |

| Package Preview: | ; | After-sales Service Provided: | No after-sales service,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support,Engineers available to service machinery overseas; |

| Place of Origin: | Hebei China; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,cash; |

| Capacity: | 100/500/1000/2000/3000 KG/H; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| Packaging Detail: | wood case export professional packing(Soap Bar Machine); | Application: | Chemical Industries; |

| Name: | Soap Bar Machine; | Supply Ability: | 10 Set/Sets per Month Steps: 1: put the soap tablets or soap tablets into the mixer, s; |

| Warranty: | 1 Year,1 Year; |

Soap Bar Machine Soap Bar Machine Soap Bar Machine Soap Bar MachineSoap Bar Machine

Steps(Commercial Soap Machine):

1: put the soap tablets or soap tablets into the mixer, start the mixer, and then put the flavor, pigment, other accessories, preservatives, etc. evenly, open the material valve, put the material into the silo, wait Mixer.

2: start the first conveyor and the first three-roll mill, and then open the silo valve, let the material into the conveyor to the grinding machine grinding.

3: Start the second and third conveyors and the second three-roll mill.

4: Wait for the material into the double vacuum after the machine, confirmed that continuous production, start the first screw, start the second screw after the material.

5: Wait for the article. Start the printer and the fourth conveyor to confirm the print speed and the same speed, the good soap loading, soap head and poor access to the conveyor back into the machine.

Established in 1992, we are professional manufacturer focused on the oil&soap machines.

Our chief engineers have been in this soap industry for over 10 years(Commercial Soap Machine).

We know well not only how to manufacturer the machines, but also how to operate the machine to product the (Commercial Soap Machine) .

We supply our clients a full range of technique assistance and make sure every client , no matter new joined or experience, can built & operate their own soap plant well. We will see to each client to get high profit by our machines.(Commercial Soap Machine)

1, We help you to figure out the most suitable and competitive soap product lines for your aimed market.

2,We help you to make the drawing of workshop building and equippment layout.

3, We supply you the good quality and stable performance soap machines , spare parts and accessories, that is the turn-key project.

4,We send our professional engineers to your plant for machine installation, staff training, etc.

5, We offer consistant technique surpport during the whole life-span of our mchines.

Export to different countries:

Product Description

Main Machines involved in soap making machine Commercial Soap Machine

1. This laundry soap production line take soap noodles as raw materials.

2. The production starts with mixing soap noodles and perfume.

3. Then the mixed soap noodles enters in the three roller mill by conveyor belt, where soap thin sheets are made.

4. The soap thin sheet then converted into desired long strip soap by the plodder machine.

4. Then the long strip soap are cut into the soap bars required size by cutting machine(there are two kinds of cutting machine.One is mechanical.The other is automatic).

5. Finally, the soap bars gets packed by packing machine if needed.

6. Soap bars can be made 60g,120g,200g,260g,and so on

Features of Soap Making Machine:

1. The finishing lines of Series for toilet and translucent soap bring together all components that are most reliable, most durable, supplied by the most famous vendors in the world.

2. The mechanical design is tend to be simplified, more robust, low energy consumption, low off-stream rate, easy to be maintained ,more people-oriented and with good view both outside and inside of the machines.

Advantages of Soap Making Machine

1.Semi automatic production line

2.Capacity can be from 75-2000kg/h.

3.Soap size depends on client demands

4.Good performance & high efficiency

Equipments working on abroad(mixing machine for soap):

Our Services

Customers visited to my factory:

Finished product:

After packing:

After-sales Service:

Before installation, the seller will provide the nformation of total line power, individual machine power, power connections, water & air input and output position, total water consumption. After the machines arrival in buyer site and put into position, the buyer must connect the water, electricity, air and vacuum gas with the machines, then the seller shall send 3~4 technicians to help start-up the line for production, on-line training and production supervision. The buyer shall pay below service ratings, as well as round-trip transportation from our factory to buyer’s factory, the visa application fee, food, transportation and accommodation.

FAQ

1, Q: Soap industry production process?

A, Basically, the soap production need 2steps:

a, using all kinds of oil&fast as material to produce semi-finished soap noodle;

b, using seme-product soap noodle to produce end bar soap.

2, Q:What is the kinds of the soaps?

A: For convenience, we separate the soap into two kinds, toilet soap for washing hand&taking bath, herbal soap, hotel soap, antiseptic soap are included;

The second kind is laundry soap for washing clothes, etc.

3,Q: What kind of oil is suitable for soap production?

A: All kinds of vegetable oil and animal fats are usable, palm oil, cotton seed oil, tallow oil, coconut oil, sunflower oil, etc.

4,Q: What is the floor of the workshop size?

A: For oil line: 35*7m with height 7m;

For soap noodle line: 25*3m with height 4m.

5,Q: What is the formula?

A: Raw material is oil, caustic soda and salt; semi-product is soap noodle, perfume and color.

Accurate formula based on your local market’s request is available after confirmation of order.

6,Q: How about the Engineer and technique support?

A: 1, We would send engineer overseas for machine installation, staff training and production test running, till your own staff can operate the machine well and product out qualified soaps.

2, During the life-span of our machines, we should give consistent technique support and service, and we are pleasure to be on service of you.(24hours on line)

shippment:

Welcome your visiting to my factory:

We are able to provide our customers with the total solution of "Soap Factory" according to the different needs of customers, including technical support and guidance on equipment for oil treatment, saponification, vacuum drying, molding and packaging as well as soap production process.

For oil processing, building and vacuum drying systems, we choose the right soap based on the type of crude oil used (coconut oil, palm oil, animal oil, etc.) and the type of finished soap (soaps, transparent soaps) System, output up to 7 tons / hour

For the forming line, we can make any formula of soap and transparent soap products. Not only can we produce 50-100 kg / h laboratory production lines for customer R & D and small-scale production, but also produce the world's largest production capacity of 4000-6000 kg / h production line, print 720 soap per minute. Soap shape customizable according to customer, and can produce two-color soap, striped soap, pattern soap and other colors, and the soap can be printed on all sides to meet the multi-faceted, personalized needs.

For the packaging line, we have been able to achieve all of the currently popular packaging formats in the market, such as carton packs, pillow packs, double paper packs and round packs.

For line-end equipment, we not only offer fully automatic and semi-automatic case packers, but also robotic palletizers to meet the needs of our customers in reducing the number and cost of personnel and increasing line automation.

In general, we are the supplier of complete equipment for soap production and provide our customers with a total solution for soap factories.

First, before the operation

1. Check if there is any foreign matter in the hopper of the upper screw and whether there is any hard material in the discharge port of the lower screw. If it is necessary to clean it.

2. Check the power, water, open the upper and lower screw cooling water valve. Check the vacuum pump, open the inlet valve.

3. Open the next screw out of the soap electric heating switch, a soapy mouth preheating, temperature control at 45 ℃ ~ 55 ℃ or so.

Second, the operation

1. When the soapstock is fed into the hopper by the conveyor belt, the upper screw motor is started.

2. To be on the screw discharge port soap material into the lower screw hopper then start the next screw speed motor.

3. When the upper and lower screws are full of material, you can turn on the vacuum pump, turn off the vacuum chamber vent valve, the vacuum control at -0.06Mpa or so.

4. During operation, pay attention to the feeding condition of feeding conveyor belt and feeding conveyor and loading condition of hopper.

5. Always pay attention to the speed, make it compatible with the printer. Note that the cooling water temperature can not exceed 20 ℃. Upper and lower screw current can not exceed the allowable range.

Third, after the shutdown

1. Before shutting down, it is necessary to finish the material in the hopper, open the vacuum pump venting valve, and turn off the vacuum pump. (Note: Be sure to open the vent valve so that the vacuum is at 0 to turn off the vacuum pump.)

2. Cut off the screw out of the soap port heating power, and the soap in the next screw finished, two hours after the shutdown, the soap out of the soap, soap clean up.

3. Turn off the power, turn off the cooling water valve, clean up the surrounding environment.

-

CANMAX fully automatic small-scale soap making machine-made soap machine solid soap production line

-

Fully automatic complete soap finishing production line laundry soap making machine manufacturer price

-

Soap Refining Machine Pressing Machine for Sale Soap Refining Machine Pressing Machine Mini Pressing Machine Soap Maker

-

Automatic Soap Sealing Machine Soap Sealing Molding Machine

-

akd wax 1840 | alkyl ketene dimer akd wax price | alkyl ketene dimer akd wax TK

-

Adjustable Manual Wood Soap Knife Cutting Tool for Handmade Soap Making and Packaging

-

Fully Automatic Laundry Soap Bar Making Machine Laundry Powder Soap Making Machine Price

-

Small Corn Peanut Seeder Manual Peanut Seeder Push Seeder For Sale

-

Soap bar press machine, bar soap machine, soap finished line

-

Detergent Soap Layering Plant Exporter

Other Products

-

$47.00 / set

$47.00 / set -

$7000.00 / set

$7000.00 / set -

$10.00 / set

$10.00 / set