Dongguan LIYI High Temperature Electric Muffle Vacuum Furnace

-

Supplier: Guangdong Liyi Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Victoria Lee -

Price: $2680.00 /set -

Min. Order: 1 set

| Color: | Requirement; | Theory: | temperature controller; |

| Warranty: | 12 Months; | Port: | Shenzhen,guangzhou,hongkong; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Brand Name: | LIYI; |

| Model Number: | LY-16-X; | Supply Ability: | 100.0 Set/Sets per Month; |

| Packaging Detail: | Standard export wooden case; | heating rate: | 0--30℃/min(recommended no more than20℃/min); |

| Classification: | Laboratory Heating Equipments; | Standard: | ASTM ISO EN JS; |

| Power supply: | 220V 50Hz / 380V 60hZ; | Package Preview: | ; |

| Volumn: | Customize; | Certificate: | CE ISO; |

| Temperature control precision: | ±1℃; | vacuum degree: | -0.1MPa; |

| Place of Origin: | Guangdong China; |

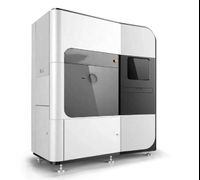

Dongguan LIYI High Temperature Electric Muffle Furnace Vacuum Furnace

This series of equipment is suitable for scientific research institutions, colleges and universities, industrial and mining enterprises ideal experimental and production equipment. It mainly used in high temperature precision annealing, micro-crystallization, ceramic glaze preparation, mold annealing, powder metallurgy, plastic powder foam test, sintering of nanometer materials, quenching of metal parts and all heat treatment required by high temperature technology.

Characteristics:

1. The furnace mantle adopts unique design of double-deck structure with High quality cold-rolled steel plate, The paint is baked at high temperature, it can be used for a long time.

2. Equipped with air-cooling system, the furnace has the advantages of balanced temperature field, low surface temperature, fast temperature rise and fall rate, etc.

3. The vacuum system adopts special design, the vacuum degree is -0.1MPa, and the atmosphere furnace pressure is 0.04MPa, automatic over-pressure and manual exhaust function, make it safe and reliable to use.

4.The inner box adopts integral seal, valve control are equipped with intake valve, exhaust valve, vacuum valve, it can be filled with nitrogen, argon and other inert gas.

5.The imported ceramic alumina poly-crystalline mullite fiber material in furnace is constructed by special technology, which is more energy efficient than traditional electric furnace.

6.The control system adopts the technology of artificial intelligence of microcomputer, which has the functions of PID regulation, fuzzy control, self-tuning, 50 segment programming, and it can program all kinds of programs of temperature rising, constant temperature, cooling temperature, and high precision of temperature control.

7. Modularized thyristor crystal control, phase shift trigger; The heating element is made by imported high quality silicon molybdenum rod.

8. The protection device adopts independent over temperature protection, overcurrent, leakage, short circuit protection

|

Model |

LY-16-17TP |

LY-16-18TP |

LY-16-19TP |

|

Furnace size(W*H*D)mm |

150*150*80 |

200*150*150 |

300*200*200 |

|

Outer size(W*H*D)mm |

735*750*1200 |

700*670*930 |

750*660*1020 |

|

Weight(Kg) |

155 |

190 |

300 |

|

power rating |

3KW |

5KW |

9KW |

|

Power |

220V 50/60HZ |

||

|

Temperature control precision |

±1℃ |

||

|

vacuum degree |

-0.1MPa |

||

|

end-use temperature |

maximum temperature 1800℃ |

||

|

heating rate |

0--30℃/min(recommended less than 20℃/min) |

||

|

Thermocouple |

Type B |

||

|

heating element |

Silicon molybdenum rod |

||

|

Display mode |

Color LED display |

||

|

gasket ring |

Fluorine ring |

||

|

vacuum pump |

Oil-immersed single rotary vane vacuum pump |

||

|

Measuring mode |

mechanical pressure gauge |

||

|

Furnace material |

High alumina polycrystalline ceramic fiber |

||

|

Furnace structure |

double-layer forced air-cooling structure |

||

Guangdong LIYI Technology Co.,Ltd is a high technology supported production-oriented enterprise who specializes in developing, manufacturing, marketing all kinds of environmental equipment. Our company has advanced technology, experienced technical management personnel and efficient professional service staffs, fine quality management and perfect after-sales service system.

Our company mainly produce simulated environmental tester, plastic and rubber tester etc. on all kinds of materials testing industries. The production base is located in the country’s manufacturing center Dongguan, Guangdong province, China. In order to service our customers better in terms of reducing costs and early delivery, in 2005 we had set up an office in Kunshan, Jiangsu province for Eastern China marketing and servicing.

Liyi deals with customers from more than 150 countries and regions. Meanwhile, we are committed to cooperate with different dealers in different countries and regions in order to offer better service. Our mission is to help every customers establish testing labs to ensure the quality of their products.

Our company will continue to develop, innovate and keep faith. We combine with the international testing standards and the specific demands of customers that may establish a new banner in Chinese testing industry.

During the whole business process, we offer Consultative Selling service.

1)Customer inquiry process:

Discussing testing requirements and technic details, suggested suitable products to customer to confirm. Then quote most suitable price according to customer requirements.

2)Specifications customize process:

Drawing related drawings to confirm with customer for customized requirements. Offer reference photoes to show the proucts appearance. Then, confirm the final solution and confirm final price with customer.

3)Order process:

We offer below business term:

|

Accepted Delivery Terms: |

FOB, CFR, CIF, EXW, DDP |

|

Accepted Payment Currency: |

USD, EUR, HKD, CNY |

|

Accepted Payment Type: |

T/T, L/C, Credit Card, PayPal, Western Union, Cash, Escrow |

|

Nearest Port: |

Shenzhen, Guangzhou, Shanghai, Qingdao, Tianjing or rquired |

4)Production and delivery process:

We will produce the machines according to confirmed PO requirements. Offering photoes to show production process.

After finish production, offer photoes to customer to confirm again with the machine. Then do own factory calibration or third party calibration(as customer requirements). Check and test all the details and then arrange packing.

Deliver the products in confirmed shipping time and inform customer.

5)Installation and after sale service:

Defines installing those products in the field and providing after-sales support.

-

High quality electric oven High temperature heating machine / electric oven / ceramic oven

-

CE Dental Furnace Dental Ceramic Furnace Hot sale porcelain dental ceramic vacuum furnace

-

Laboratory Dewaxing Furnace/Dental Laboratory Products Dental Machine Tube Furnace Laboratory Heating Equipment Resistance Wire CN;HEN CE

-

Intelligent digital display electric heating mantle

-

CE Certificate Dental Instrument New Design 6010 Ivoclar Dental Ceramic Furnace

-

Joan Lab Multifunctional Magnetic Stirrer With Heating Laboratory Equipment Manufacturing

-

CVD machine, MPCVD machine for diamond production

-

Hot selling professional synthetic cvd diamond making machine

-

Laboratory Digital Heating Plate High Temperature Mini Stirrer Magnetic Electrochemical Stirrer with Heating Function

-

JOANLAB Digital Electric Furnace Magnetic Stirrer HSC-19T with Heating Function

Other Products

-

$580.00 / set

$580.00 / set -

$1580.00 / set

$1580.00 / set -

$2150.00 / set

$2150.00 / set -

$500.00 / set

$500.00 / set -

$3580.00 / set

$3580.00 / set -

$2580.00 / set

$2580.00 / set -

$2680.00 / set

$2680.00 / set -

$2580.00 / set

$2580.00 / set