Soild slurry pump sand pump impeller

-

Supplier: Shijiazhuang Shiyi Pump Industry Co., Ltd. -

Region: Hebei, China -

Contact: Ms. Dilys Liu -

Price: $50.00 /piece -

Min. Order: 1 piece

| Supply Ability: | 200 Ton/Tons per Month; | Casting: | Resin sand casting or Lost foam casting; |

| Port: | Tianjin Port; | Application: | Industry pumps; |

| Delivery Detail: | 7 days in stock; | Pump Parts & Accessries: | Impeller; |

| OEM: | Acceptable; | Structure: | Single-stage Pump; |

| Standard or Nonstandard: | Standard; | Place of Origin: | Hebei China; |

| Payment Terms: | L/C,D/P,T/T; | Brand Name: | Shiyi; |

| Material: | Alloy Steel; | Usage: | Slurry Centrifugal Pump; |

| Packaging Detail: | Seaworthy plywood Cases; | Certification: | ISO9001; |

| Model Number: | Closed or Open; | Surface Treatment: | Sand Blasting; |

| Size: | Customer's Drawings; | Process: | Casting + Machining; |

Slurry Pump Impeller is one of the most important spare parts pumps. When impeller working, the slurry pump could meet the requirements of the equipment. However, it is a component, which is worn out very easily. Therefore, for long service life of the impeller, the material plays an important role here.

Strictly material components controlling procedure

a) Analysis before and after the stove

b) Professional mould keeping and using

c) Impeller balance testing and revising by advanced quipment

d) Delicate both in dimension and surface

Shijiazhuang Shiyi Pump Industry Co.,Ltd founded in 2006 which is a big professional high-tech industrial pump manufacturer engaged in researching and manufacturing slurry pumps of wear and corrosion resistant materials and OEM processing.

Our production area covers an area of 40000 square meters, the total production capacity of an annual output is 10000 units (sets), and the annual output of all kinds of high chromium alloy castings is 2000 tons.

The R&D of products adopts CFD and CAPP technology.We use both the resin sand molding and the new foam lost for casting process,the max casting weight is 8-10 tons.

Our production area is divided into five districts,one warehouse and two centres.

Namely five districts are mould casting, heat treatment, fine machining, forge welding and assembly coating;

One warehouse is the middle stock for spare parts;

Two centres are quality inspection are pump test station.

We have two 20 cubic resistance-type heat treatment furnace,and there are 4.2m and 4.5m vertical lathe and other more 20 units machine tools in the machining workshop.

In addition,there are various types of hoisting equipment,metal cutting and welding equipment,impeller level tuning equipment,molding equipment,sandblasting polishing equipment,high pressure test station,high-precision testing equipment, analytical instruments and so on.

-

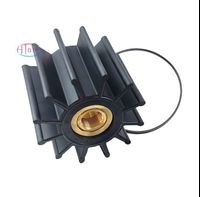

DOOSAN 65.06804-000 Marine Impeller JMP 8201-01 Flexible Marine Impeller for DJ Pump Open Rubber Pump Parts

-

replace water pump impeller kit Sherwood 26000K-SHW Ancor 5063 3972366 DJ PUMP 08-34-1201 repair kit 19879 O-Ring

-

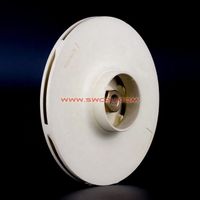

DONGYIN 4SD 3T Water Pump POM Plastic Impeller Submersible Pump

-

Industrial water pump air compressor motor plastic fan blade

-

centrifugal compressor alloy steel impeller

-

Manufacturers sell custom slurry pump impeller pump accessories blade impeller

-

Plastic impeller industry centrifugal water pump

-

Factory direct sale Y2 plastic motor blade motor wind blade

-

JetMan Outboard Jet Impeller Series Medium, Part No.1737, 8.23 (for liner #1521)

-

Flexible Rubber Impeller Replacement Jabsco 18786-0001 CEF 500153 CAT 7E3022 9Y5427 Neoprene Impeller