LPG And Natrual Gas Burner For Ceramic Kiln

-

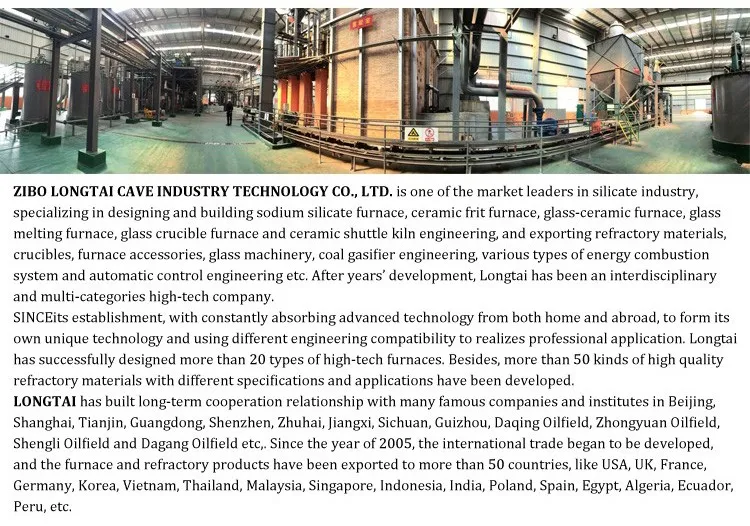

Supplier: Zibo Longtai Cave Industry Technology Co., Ltd. -

Region: Shandong, China -

Contact: Ms Emily Ding -

Price: $35.00 / >=10 pieces -

Min. Order: 10 pieces

| Working way: | Self-suction; | Capacity: | 1-40t/h; |

| Product name: | Ceramic Kiln Cast Iron Venturi Gas Burner; | Gas type: | Natural gas;liquified pertroleum gas; |

| Type: | Gas Burner; | Payment Terms: | T/T,Western Union,MoneyGram; |

| Place of Origin: | Shandong China (Mainland); | Port: | Qingdao; |

| OEM: | Available; | Brand Name: | LONGTAI; |

| Certificate: | ISO9001:2008; | Supply Ability: | 10000 Piece/Pieces per Month Ceramic Kiln Cast Iron Venturi Gas Burner; |

| Application: | Boiler system; | Heat consumption: | 20000-25000Kcal/h; |

| Packaging Detail: | Exporting packing for Ceramic Kiln Cast Iron Venturi Gas Burner; | Structure: | Refractory spurt head;steel bowl;gun body;and other assembling unit; |

| Color: | Customers' Requirement; |

Q1: How long is the warranty of the rotary kiln?

Our warranty period is one year generally.

Q2: How long shall we replace the refractory brick?

Usually 6-12 months(Depends on the time and temperature.)

Q3: Can I visit your factory?

Yes. We warmly welcome you to visit our factory.

Q4: Do you provide equipment operation training?

Yes. We can send professional engineers to the working site for installation, adjustment, and operation training. All of our engineers have passports.

Q5: Do you provide whole rotary kiln flowchart?

Yes. Our experienced engineers are specialized in designing process flow for various projects, such as cement production line, quicklime production line, magnesium production line etc.

Q6: Can you test our samples?

Yes. You can send your samples to us for test and analysis.

-

China factory hot selling DUNGS replacement pressure reducing valve, high quality burner parts

-

Pizza oven for industrial pizza China with small gas oven for sale

-

Furnace Industrial Gas Burner Manufacturer

-

Waste oil burner nozzle siphon type full cone oil fuel nozzle air atomization sprayer diesel heavy oil nozzle burner accessories

-

YORK Oil filter with AL cup for burner and boiler replaces Giuliani Anello oil filter

-

Bairan B26 light oil burner, diesel burner, primary fire burner

-

China cheap high quality small portable gas burner for pizza oven oven diameter 110cm-140cm NPG and LPG industrial gas burner

-

Two-stage gas burners RIELLO 40 FSD SERIES

-

High Quality Hot Sale Combination Boiler Spare Parts Air Pressure Switch Sensor Pump Motor - Copo Safety Valve

-

Hot Sale High Quality Combination Boiler Spare Parts and Accessories Gas Valve Expansion Tank Pressure Gauge

Other Products

-

$35.00 / piece

$35.00 / piece -

$35.00 / piece

$35.00 / piece -

$35.00 / piece

$35.00 / piece