Round/square/rectangle Thickness 0.5-3.0mm cutting type metal saw cutting pipe making machine

-

Supplier: Foshan Jopar Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Eric Xiao -

Price: $45000.00 /set -

Min. Order: 1 set

| Pipe Material: | Stainless Steel; | Package Preview: | https://sc02.alicdn.com/kf/HLB1JizlNFYqK1RjSZLeq6zXppXaW.jpg_640x640.jpg; |

| size of machine: | 32*1.8M; | Place of Origin: | China; |

| Condition: | New; | diameter range: | 50-114mm; |

| Power(W): | 15KW+15KW; | Type: | Pipe Mill; |

| cutting type: | metal saw cutting; | Name: | pipe making machine; |

| Material: | Stainless Steel; | Function: | Metal Processing; |

| Warranty: | 1 year; | After-sales Service Provided: | Online support,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; |

| Key Selling Points: | Easy to Operate; | Pipe shape: | Round/square/rectangle; |

| Dimension(L*W*H): | 32*1.8M; | Selling Units: | Single item; |

| Application: | Other; | Certification: | 5-15T; |

| Single gross weight: | 6,000 KG; | Thickness: | 0.5-3.0mm; |

| Weight: | 8T; | Color: | At your choice; |

| Production Capacity: | 0.12m/min; | Single package size: | 3500X150X150 cm; |

| Package Type: | Use standard wire and bracket to secure the large mechanical. Use shock-film protecting the external motor.; | Applicable Industries: | Manufacturing Plant; |

| Brand Name: | Jopar; | Voltage: | 220/380/415/420/440V; |

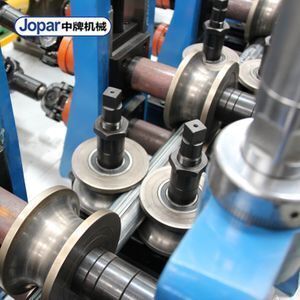

| Horizontal axles: | 60mm; |

product detailed

Finished Products

industrial control pipe production line is mainly used in the production of industrial

stainless steel pipe. Because stainless steel pipe technology matures,

has been replaced in many areas seamless (such as chemicals, pharmaceuticals, wineries, oil, food, automotive, paper,

air conditioning and other industries and are widely used.)

automated production processes: The uncoiling, cleaning equipment,

feed orientation, forming, welding, weld leveling within and outside the weld grinding, shaping, sizing, solution treatment,

the final sizing, alignment, testing, spray code, length, cut off (coil),

splicing and other continuous molding process. Fine structure, easy operation, manufacturing, first-class quality

Application

Advantage

A; Adopt first class suppliers, like Siemens,ZhuJiang Gearbox, Dongfeng Auto Parts

B ; Adopt imported CNC machine from Taiwan, Ensure that customers can safe use

C ; Adopt high-tech. Fine motor structure design, Design, Stable performance, Save energy and environmental protection

D; Humanized operating system design, Easy to learn, Easy operating

E ; All products pass ISO9001 international quality management system certificate, First class, Brand guarantee

F ; Jopar has 30 inventions, Practical patents, Like big tubes(168*0.35mm, 426*10mm)

G ; Our products are mainly exported to India, Japan, Thailand, Vietnam, Indonesia, Malaysia, Russia, Poland, Myanmar, Colombia and so on.

| Model | Horizontal shaft O.D | vertical shaft O.D. | tube range | Thickness | Drive Motor | Dimension |

| ZP-I40 | 40mm | 25mm | ∅8-51mm | 0.3-2.0mm | Front:7.5 kw Fear: 5.5kw | 29m*1.5m |

| ZP-I50 | 50mm | 30mm | ∅25-76mm | 0.4-2.5mm | Front:11 kw Fear: 7.5kw | 32m*1.5m |

| ZP-I60 | 60mm | 40mm | ∅50-114mm | 0.5-3.0mm | Front:15 kw Fear: 15kw | 35*m1.8m |

| ZP-I80 | 80mm | 50mm | ∅89-168mm | 0.8-4.0mm | Front:18.5 kw Fear:18.5 kw | 40m*2.5m |

| ZP-I100 | 100mm | 60mm | ∅114-219mm | 1.0-5.0mm | Front:22 kw Fear: 22kw | 43m*3.0m |

| ZP-I120 | 120mm | 80mm | ∅168-325mm | 1.5-8.0mm | Front:37 kw Fear: 37kw | 48m*3.0m |

Company Information

Foshan Jopar Machinery Co., Ltd is a professional manufacturer of stainless steel pipe making machines

and concentrates on the research and development, design, production, sales and supporting services.

Our company conducts with modern managerial regulations and adopts imported precision mechanical

processing machines. What’s more, with continuous innovation, higher product quality and

upgrading after-sales services, it helps gain large number of loyal customers from all over the world.

Our products are exported to South America, Eastern Europe, India, Indonesia, Japan, South Korea, Malaysia,

Thailand and other countries and districts which requires a wide range of application of decoration, automobile,

sanitary ware, piping transportation and relative industries.

Especially for the following products are highly awarded and popular, such as tube mill, stainless steel pipe making machine,

inside bead remove machine, in-line bright annealing machine, pipe polishing machine, ERW tube mill, pipe cutting machine,

pipe chamfering machine, pipe embossing machine, roller sets and moulds, etc. Additionally, our company can also provide

specialized factory planning solutions and turnkey projects to our customers.

Under the company concept of Innovating to create win-win cooperation, Jopar Machinery has been always keeping on the

road to sustainable development and establishing a competitive world-class enterprise of stainless steel whole-plant equipments.

All of us are looking forward to cooperating with you around the world.

Serivices: stainless steel pipe making machine, ss tube mill, ss pipe mill, erw tube mill, carbon steel tube mill, high frequency tube mill, pipe/tube polishing machine,

pipe embossing machine, inside welded bead remove machine, inline bright annealing machine, pipe mold, roll set, etc.

Packging and shipping

Our customer

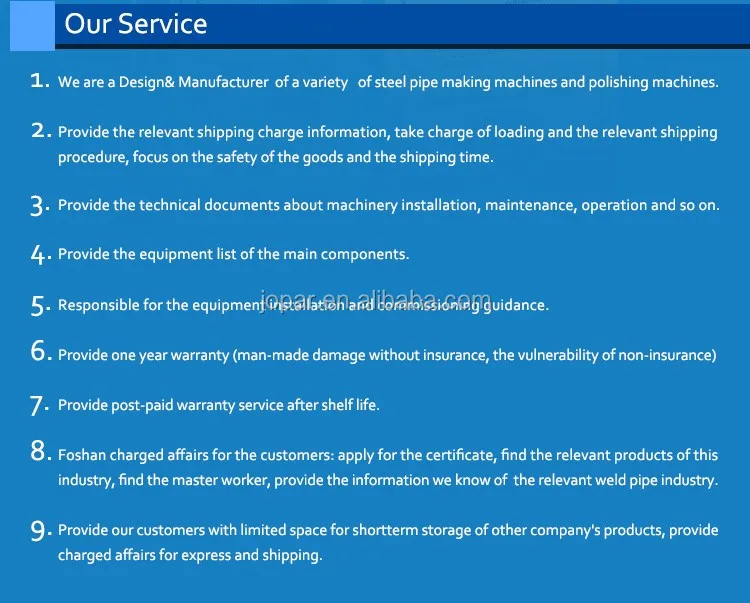

Our service

Our certificate

FAQ

Q:Are you manufacturer?

A:Yes,we are specialized in manufactured the pipe mill, tube making machine

Q:What kind o f payment term you can do?

A:We are flexible about payment terms, contact us if you want to have learned the information details.

we can accept L/C , D/A , D/P , T/T , Western Union , Money Gram

Q:What info you need to learned before you make the proposal?

A: The stability and reliability of the pipe making machine or how long the service life or after sale service

or quality of tube making making machine or production capacity

Q: What should I do if I just start a new business?

A: we provide good pre-sales and after-sales service.help you to solve the problem of material

(steel coil) purchase,employee train, arrangement the engineer to install machine at the buyer production site

Q:How about your QA?

A:We have professional team to design, production the pipe making machine strict to carry out quality inspection ,this is our strengths:

(1)Every gear box will be tested for 8 hours with oil inside to guarantee it no oil leakage

(2)Every shaft will be inspected for the centering jumpiness.

(3)Every roller will be checked to make sure its in the range of tolerance critical parts will be inspected for all dimensions.

Q:Why I choose you,what differences between you and other suppliers?

A:We are concentrate on designing and development of the pipe making machine more than ten years.

Especially our industrial pipe making machine is specialized in manufactured the stainless steel pipe

Contact Us

-

Pipe making machine making square pipe machine for sale

-

2023 new shower hose making machine for flexible braiding stainless steel 201 304 brass nuts with pvc mixer insert

-

Pakistan Market 304/201 SS Coil Decoration Square Tube Making Machine Tube Machine

-

Tube Mill Rolls & Materials High Quality Steel Tube Welding Machine Korea Spare Parts Indonesia Supply Saudi Arabia

-

Lower Price Attached Vibratory Cement Batch Concrete Pipe Making Machine Manufacturer

-

Large Metal Conduit Making Machine/Galvanized Steel Conduit Forming Machine/Double Lock Flexible Pipe Making Machine

-

Pipe making machine carbon steel pipe making machine

-

Flexible metal pipe making machine/Flexible metal pipe making machine

-

Pittsburgh lock forming machines, lock forming machines

-

Foshan CS/carbon/stainless steel/iron welded round pipe production line pipe making machinery