Aluminium Foil Container Machine Fully Automatic Kitchen Foil Tray Making Machine

-

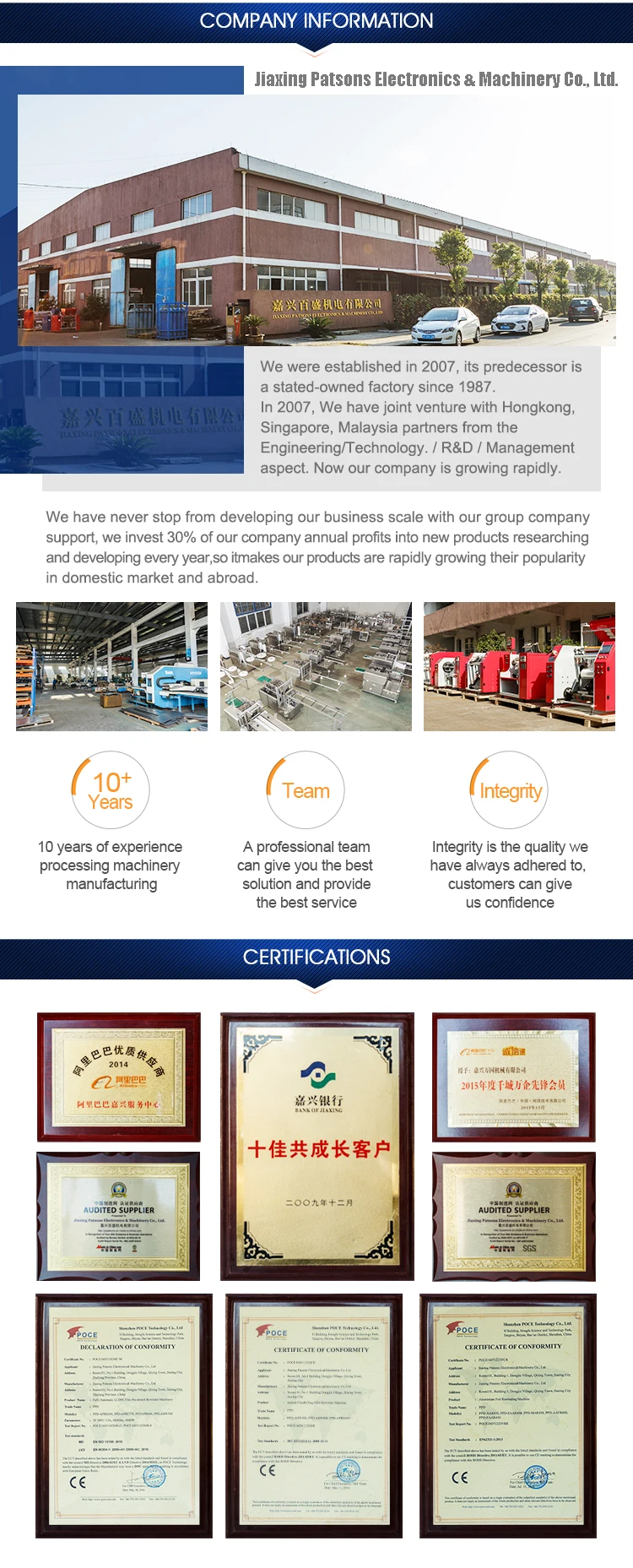

Supplier: Jiaxing Patsons Electronics & Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr GB Mou -

Price: $1500.00 /unit -

Min. Order: 1 unit

| Automatic Grade: | Automatic; | Slide stroke speed: | 35-90pcs/min; |

| Brand Name: | PPD; | After Warranty Service: | Video technical support,Online support,Spare parts; |

| Port: | Any port of China; | Certification: | CE,SGS,ROHS,BV; |

| Supply Ability: | 5 Unit/Units per Month; | Local Service Location: | Malaysia; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; | Nominal pressure: | 630KN; |

| Key Selling Points: | Easy to Operate; | Name: | Fully Automatic Kitchen Foil Tray Making Machine; |

| Aluminium foil roll inner diameter: | 76mm or 152mm option; | Tension control: | Electric Magnetic Brake 100NM; |

| Slide block stroke: | 180-260mm; | Showroom Location: | Malaysia; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Effective length of feeding roll: | 900mm; |

| Max diameter of aluminium foil roll: | 1000mm; | Condition: | New; |

| Place of Origin: | Zhejiang China; | Model: | PPD-A63T; |

| After-sales Service Provided: | Online support,Free spare parts; | Max feeding width of aluminium foil roll: | 880mm; |

| Packaging Detail: | Pakcaging Details:Packing in standard export wooden case.; | Warranty: | 1 year; |

Fully Automatic Kitchen Foil Tray Making Machine

Fully automatic kitchen foil tray making is a fully auto production line for production of aluminium foil container,aluminium foil tray,aluminium foil dish,aluminium foil plates etc foil products.

The complete production line is consist of 4 parts, aluminium foil feeding machine,high accurary press machine,aluminium foil punching mould and auto stacker.

Fully Automatic Kitchen Foil Tray Making Machine

Model:PPD-A63T

I.Aluminium Foil Feeding Machine:

| Lubrication function | Automatic equal oil coating design with no weinkle trouble |

| Max feeding width of aluminium foil roll | 880mm |

| Max diameter of aluminium foil roll | 1000mm |

| Effective length of feeding roll | 900mm |

| Aluminium foil roll inner diameter | 76mm or 152mm option |

| Tension control | Electric Magnetic Brake 100NM |

| Feeding system | Servo System |

| Feeding speed | 0-500m/min |

| Feeding length&precision | +0.1 mm |

| Power | 1.5kw |

II.High Accuracy Press:

| Press Model | 63T |

| Nominal pressure | 630KN |

| Slide block stroke | 180-260mm |

| Slide stroke speed | 35-90pcs/min |

| Range of mould height | 340-420mm |

| Max size of mould | 1100x900mm |

| Weight | 8800kgs |

| Power | 11kw |

| Dimension | 1500x2200x3500mm |

III.Punching Mould

| Aluminium foil thickness | 0.03-0.35mm |

| Aluminium foil container shape | Round,square,heart etc |

| Aluminium foil container color | Silver,gold,red etc |

| Aluminium foil container size | as customized |

IV.Auto Stacker:

| Model | AS-800 |

| Lane quantity | 3lanes |

| Belt width | 900mm |

| Belt height | 850-1200mm |

| Min container dimension | 120*120mm |

Max container dimensions Top out size(LxW) | 800*400mm(1 lane) 400*400mm(2 lanes) 250x400mm(3 lanes) |

| Max height of stacking | 400mm |

| Power | 1.2kw |

1 Q: Which machine do you require?

A: We have many models of machine, please contact our sales

office who will assist you to select the best machine to suit your requirements.

2 Q: Can you make the machines as buyers’ requests for us?

A:Yes. We have a professional RD team with rich experience to design and manufacturing.

3 Q: What is your terms of payment ?

A: By TT or LC

4 Q: How long is the warranty?

A: Machine with one year warranty, if any parts broken,we will send new spare parts to buyer via DHL within 24 hours,life-long maintenance

5 Q: How long is your delivery time?

A: 3 weeks for standard model machine,30 working days for customized model.

6 Q:How do you pack the machine?

A: Free fumigation export plywood cases

7Q:How do you deliver the machine?

A:By sea,by air,by train or others

8 Q: Will you support oversea service?

A: Yes, our engineer can go to buyer’s factory to install the machine and train the operator for buyer.

We can also provide 2 days free training in our factory,with food and accommodation.

-

Lunch Box Hot Blow Molding Machine

-

Carton cardboard box forming machine carton forming packaging machine

-

High speed automatic partition machine

-

Match Biscuit Roller

-

SW 900 Automatic Grooving Machine

-

Carton Box Making Machine Automatic Corrugated Cardboard Box Flexo Die Cutting Machine/Printing Machine/Carton Slotting Machine

-

Carton Box Case Liner Bag Placing Machine

-

One Piece Cardboard Wrap Box Former

-

One Piece Folder Cardboard Box Forming Machine

-

Poly Bag Inserter Machine for Placing Liner in Carton Case

Other Products

-

$25000.00 / unit

$25000.00 / unit -

$1500.00 / unit

$1500.00 / unit