SMCLM-7A Full Automatic RFID Smart Card Inlay Laminator

-

Supplier: Shenzhen Smart Industry Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Smart Zou -

Price: $139000.00 /set -

Min. Order: 1 set

| After-sales Service Provided: | Video technical support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support; | Voltage: | 380V or 220V or 110V by order; |

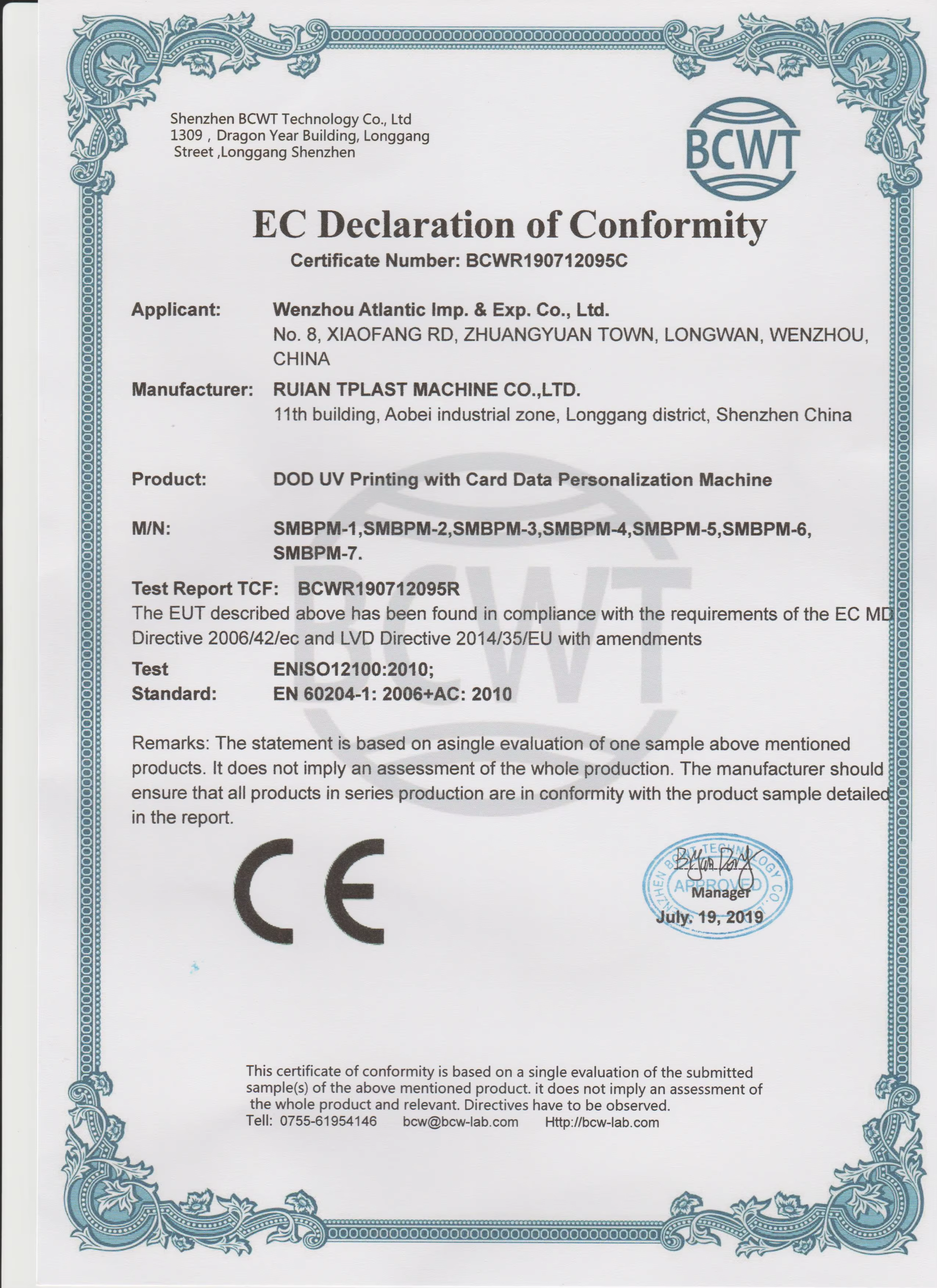

| Certification: | ISO9001:2015 and CE; | Power(W): | 60KW; |

| Place of Origin: | Guangdong China; | Port: | Shenzhen; |

| Supply Ability: | 300 Set/Sets per Year; | Applicable Industries: | Manufacturing Plant,Machinery Repair Shops,Printing Shops,Advertising Company; |

| Weight: | 7000KGS; | Brand Name: | SmartManufacture; |

| Warranty: | 2 years; | Dimension(L*W*H): | 4500mm(L) * 3800mm (W) * 2010mm (H); |

| Packaging Detail: | Professional vacuum packaging with standard export wooden box.; | Payment Terms: | L/C,T/T,Western Union,MoneyGram; |

| Condition: | New; |

We're 19 years Know-How on card lamination machinery, this new offer SMCLM-7A Full Automatic Rotary RFID Contactless Smart Card Laminator System focuses on laminating various plastic cards, inlays sheets and contactless cards with revolutionary innovation!

The system specially designed for mass production of big sheet likes 6*8/6*9/7*8 with amazing and innovative design.

Hydraulic Pressure System Chiller Cooling System

lamination openings automatic transfer loading station

Advanced Heating System

The aluminum-alloy press platen leads the excellent even heating transit, controlled by PLC for high precision temperature and pressure transmitting frequency converter.

15 heating rods in each press platen. Advanced sensor & PLC controls each press layer's temperature precisely. The heating temperature is up to 220C with tolerance of 1C.

Quick and even heat transferring will shorten the cycle time. High efficiency, energy saving and environment friendly are also advantages.

Advanced Pressure Control System

Pressure range 0-16MPa, Controlling precision 0.1 MPa, which achieved by advanced pressure sensor and PLC control system.The top-level hydraulic system will ensure the reliable & stable working.

High Pressure Accuracy and Even Temperature

In heating & cooling press stations, there are 4 hydraulic cylinders working together and pressures controlled by 2 motor and hydraulic pumps. 19 years practices authenticated that precised temperature control comes from simple temperature setting!

Amazing and Innovative Design

Thanks for 20 years experience on card lamination system, as the biggest market-share players from China, we released such simple and effective rotary lamination system with auto loading and unloading system.

Leading and Outstanding Tech

The advanced pressure and temperature control system, the shortest operation route including material loading or unloading, transfer loading system,also the most effective rotary technologies in world market.The compact size and floor space allows you easily machine location and installation.

Unique Design and Tech For Slight-Press Starting

Will increase the production yield and make final card lamination quality in top level.

Easy Operation and Maintenance

All system controlled by PLC and operated by touch screen. All parameters set on human screen. Easy operation and maintenance are the highlights. 10 groups laminating parameters stored in system. Get easy operation for repeat order.

Durable 7days*24hours/day Industrial Concept

19 years experiences and numerous references will bring you the proven system and reliable services. The machine is suitable for the 7days*24hours/day mass production.

Modular Design and Flexible Tailor-Made Service

The innovative modular design and rotary loading and transportation system makes the simple structure. Any layout including 6*8 or double 3*8, 6*9 and 7*8. Custom made service for any global user!

Model | SMCLM-7A Full Automatic Rotary RFID Contactless Smart Card Laminator |

Platen Press Area | 700mm*550mm (our standard model) , Other dimension on your request |

Max. Material Sheet Size | 680mm*550mm, please state your laminate sheet size when ordering |

Support Sheet Layout | 3*7, 3*8, 3*9 or double packages for 3*7, 3*8, 3*9 |

Lamination Station | 1 tower for heating lamination press 1 tower for cooling lamination press |

Heating Method | Electric Heating Rod for maximum 400C |

Cooling Method | outer chiller / Cooling Machine, automatic water cyclic utilization |

Opening/Daylight | regular 7 hot and 7 cold, maximum 9 hot and 9 cold by customized demand |

Opening Space Distance | 50mm, 10-15 packages laminate sheets in each opening |

Cycle Time | 15-18minutes Hydraulic Pressure |

Control Method | PLC and Touch Screen |

10 Parameter Records | setting could be stored in System easy to repeat order and production management |

Power Supply | 3 phase and 5 lines, AC 380V, 50-60Hz |

Consumption | 60 KW (for regular model of 7x8 layout), cost 12KW per hour |

Net Weight | 7000 KGS |

Machine Dimension | 4500mm(L) * 3800mm (W) * 2010mm (H) |

Advised space for installation | 6500mm (L) * 6000mm (W) * 3000mm (H) |

Leading Time | 60 working days (10-12weeks) |

FAT/Training Time | 2-3 days in supplier assembly factory |

Operator | two operate positions for 2 operators, save time, more faster |

Quality Warranty: 2years.

Delivery Time: 60days from receive advance payment.

Installation and training: we offer engineers to buyer's factory for installation and training, or buyers arrange engineers to our factory for training.

Professional vacuum packaging with standard export wooden box.

Contact Us: www.smartmanufacture.com

Shenzhen Smart Industry Co., Ltd. ISO9001:2015 and CE certificated

Mobile number & What'sapp & Wechat: +8613088669057

-

Paper Hot Melt Adhesive Coating Laminating Machine Label Paper/Film Label Laminating Machine

-

LBS1000 Roll Photos 82mm Manual cold laminator laminating machine

-

Pvc Card Lamination Id Card Laminating Bank Card Making Machine

-

Extrusion Coating Laminating Machine EMMA Extrusion Coating Laminating Machine 1400 Extrusion Coating Laminating Machine

-

Machine Manufacturing Smart Card Credit Card Manufacturing Machine ATM Card and Chip Manufacturing Machine

-

New Design A6 PVC ID Card Laminating Machine

-

A4 PVC Card Laminator and ID Card Laminator

-

Industrial Small Fabric Foam Composite Machine

-

roll-to-roll paperboard laminating machine

-

construction use and thickness 170mm 200mm EPE foam mattress thickening machine