D15 Rotating Tank Washing Nozzle, CIP rotary spray head, SS316, Max. tank diameter0.8m

-

Supplier: Cleaning Intelligent Equipment Technology (Guangzhou) Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Jane Chen -

Price: $10.00 /piece -

Min. Order: 1 piece

| material: | SS316; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Applicable Industries: | Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory; | Application: | cleaning and rinsing of small tank / kegs / machines; |

| MOQ: | 1pcs; | Max. tank diameter: | 0.8m; |

| Ball diameter: | 15.8mm; | Condition: | New; |

| Filtration: | line strainer with a mesh size of 50 mesh; | Connection: | 1/8" BSPP, 10mm slip-on, or welding; |

| Port: | Guangzhou; | Supply Ability: | 1000 Piece/Pieces per Month; |

| Feature: | Self-rotating, Double bearing design; | Packaging Detail: | 60*40*30cm; |

| Place of Origin: | Guangdong China; | spray angle: | 360°; |

| Model: | Rotating Tank Washing Nozzle, CIP rotary spray head; | Brand Name: | Cleaning-Spray; |

D15 Rotating Tank Washing Nozzle, CIP rotary spray head

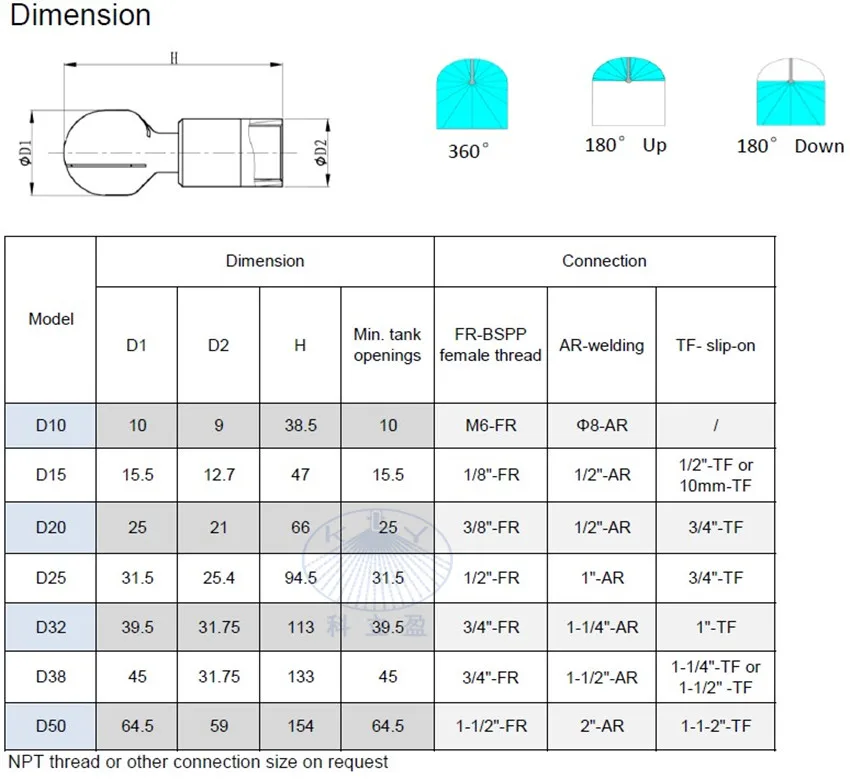

| Model: | D15 CIP rotary spray head |

| Material: | 316L ss |

| Connection: | 1/8" BSPP, 1/4"NPT, 1/2" slip-on or welding |

| Bearing: | double ball bearing |

| Pressure: | 1.5-3 bar |

| Diameter: | 16.5mm |

| Spray diameter: | 0.8m |

| Temperature: | 130° |

| Installation: | Operation in every direction is possible |

| Filtration: | Line strainer with a mesh size of 50 Mesh |

| Application: | rinsing and cleaning of tank or equipment |

Design features :

1. Double bearing design with excellent rotation effects, and better stability and longer life

2. Self-cleaning self-lubricating design

3. 360 degree self-rotating cleaning nozzle

4. Low consumption of liquid, operating at low pressure

5. Driven and lubricated by the cleaning fluid

6. The compact and hygienic design meets requirements for use in CIP system

Common application:

- Soup kettles

- Yeast propagation tanks

- Batch processing vessels

- Fluid bed dryers

- Ink and paint mixing vats

- Brew kettles

- Storage tanks

- Spray dryers

- Commercial ovens

e.g: in food industry, beverage industry, pharmaceutical industry and chemical industry

Benefits:

- Provides a high energy impinging spray for deep cleaning.

- Reduces water consumption.

- Reduces chemical consumption.

- Increases vessel availability.

- Reduces confined space entry.

- Provides consistent cleaning.

- Helps fight against bacterial infections and other “off taste” producing elements

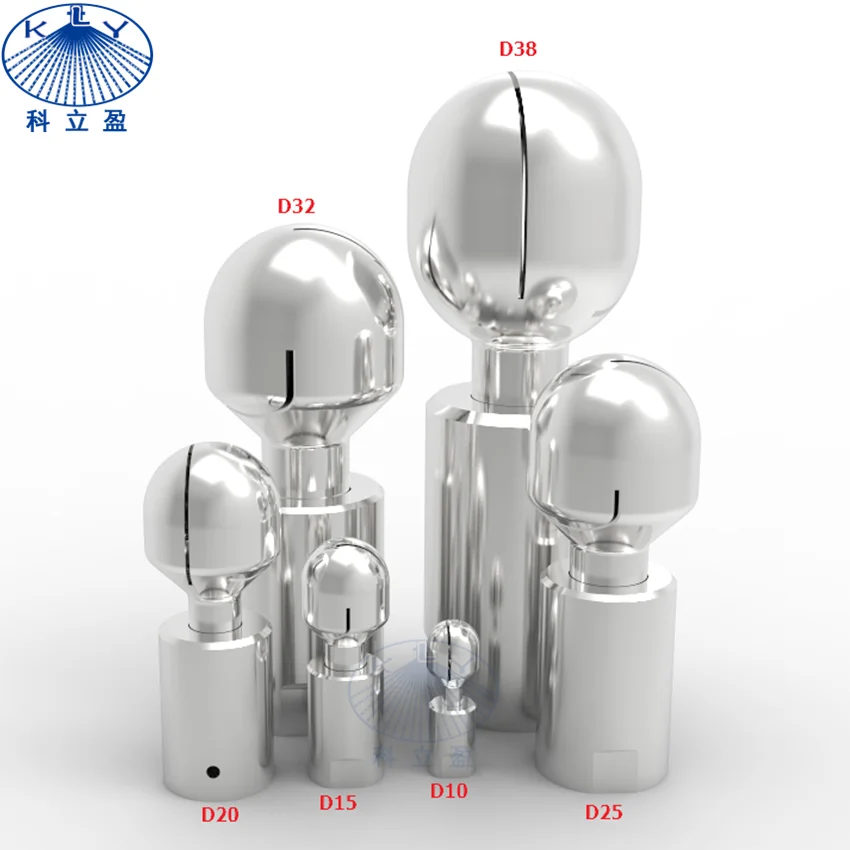

Product Photo:

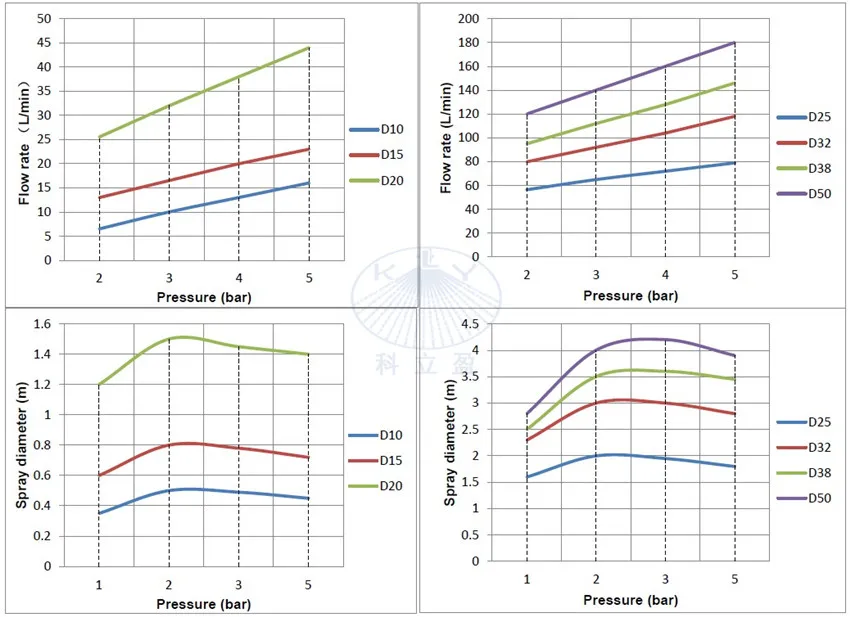

Performance Data

Application of tank washing nozzle:

Tank washing nozzles are used to rinse and clean tank to 3m diameter.

D321/2" rotary spray heads are used to rinse and clean 1000L IBC totes/ tanks.

Product Categories

Tank cleaning nozzles Full cone nozzles

Air atomizing nozzle Air nozzles

Flat fan nozzles Hollow cone nozzles

Company photos:

Exibition photos:

Company information

Guangzhou Cleaning-spray Equipment Co., Ltd is one of leading company in China specialized in manufacturing and selling tank cleaning nozzles, industrial spray nozzles and other spray product which are widely used in Pharmaceutical, Chemical, Food and Beverage and other industry. We can provide you with optimal solution according to your requirement.

Our Services

1. Reply your inquiry within 24 hours.

4. Best after-sale service. We accept return if the products is not right specification or damaged when arrived.

5. Payment Term:T/T , Western Union, Secure payment

6. Delivery Term: China Post/ TOLL/ DHL/ UPS/FEDEX Express; Air/ Sea Transportation

7. All products can be customised.

FAQ

1,Can the products be customized?

Yes, we accept OEM, just send us your layout or actual sample, we can arrange production according your design.

2,Is the MOQ fixed ?

For mass production orders,the MOQ cannot be lowered according to production requirements.For stock items,order quantity can be negotible.

3,How to order?

Please send one RFQ to us, our sales will confirm with you about the specification or other required things, then will send an official invoice to you via mail, which will be included the details of your order and bank information of our company.

4,How to pay?

We accept the payment via ESCROW, T/T (bank transfer) and Western Union, please inquire us about the details in advance.

5,How long about the production leadtime?

Different products and quantities have different procedures and different timing,normally it needs about 7-14 working days.

6, How to Deliver?

By air, by sea or by express(Fedex, DHL, UPS, TNT etc)

7,How to return ?

Acceptable to the returns when you receive the products because of the following reasons.

1. Product was damaged, lost or missed

2. Different specification from required one.

Before ordering, please select a suitable product for you. As you know, all of us don't expect the return. If your return is the result of our error (you received an incorrect or defective item, etc.) we will cover the cost of return shipping. Please note that you are responsible for the cost of shipping for returns not due to our error.

-

BYCO High Pressure 1/4 Inch 6502 6503 9502 9503 11002 11003 Carpet Sprayer High Pressure Cleaning Flat Fan Nozzle

-

Air Knife Aluminum Alloy Super Compression Air Knife Air Curtain Drying Nozzle Air Knife Dust Removal and Dehydration Knife Set 2022

-

High Quality Marble Stainless Steel Wire Hull Underwater Floor Cleaning Brush

-

AMSTURDY VRT3 Pressure Washer Parts Regulator Bypass High Pressure Washer Unload Valve

-

30" High Pressure Aluminum Hard Surface Cleaner Rotary Flat Water Broom

-

Automatic car cleaning brush with Eva foam broom

-

High Pressure Rotary Ceramic Core Sewer Ejector Drain Cleaning Nozzles For Cleaning Equipment Parts

-

High pressure water gun for car washing machine

-

AMSTURDY PGK02 Clean Car Wash Sprayer Portable Short Power High Pressure Car Wash Machine Spray Gun High Pressure Cleaning Gun

-

Roller Brush CRB Counter Rotation Machine Brush Carpet Equipment

Other Products

-

$130.00 / piece

$130.00 / piece -

$500.00 / piece

$500.00 / piece