DEUMA China factory price for Column Boom rotator combined strip cladding Submerged Arc Welding machine

-

Supplier: Deuma Automation And Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms. Joy Peng -

Price: $186000.00 /set -

Min. Order: 1 set

| Product name: | SAW Welding machine; | Rated Duty Cycle: | 100%; |

| Packaging Detail: | Wooden case, pallet, electrical control cabinet adopts plywood case; | Power(W): | customized; |

| Place of Origin: | Guangdong China; | Welding mode: | automatic and joystick; |

| Port: | Zhuhai sea port or shenzhen sea port; | max. pre-heating temperature: | 400°; |

| Pulse Frequency: | customized; | Arc Current: | customized; |

| wall thickness: | 15-200mm; | colour: | Customized; |

| wire diameter: | 3.0mm ,3.2mm ,4.0mm; | Brand Name: | DEUMA; |

| Effective stroke of cross boom: | 8000mm; | Usage: | welding; |

| Warranty: | 1 year; | Condition: | New; |

| After-sales Service Provided: | Field installation, commissioning and training,Field maintenance and repair service; | Payment Terms: | L/C,T/T; |

| Pilot Arc Current: | customized; | Dimensions: | customized; |

| Motor Type: | DC MOTOR; | welding power source: | ESAB1251; |

| Voltage: | customized; | Supply Ability: | 30 Set/Sets per Month; |

| Applicable Industries: | Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Construction works ,Energy & Mining; | Certification: | ISO; |

| Effective stroke of vertical column: | 6000mm; | Model: | AMFR series; |

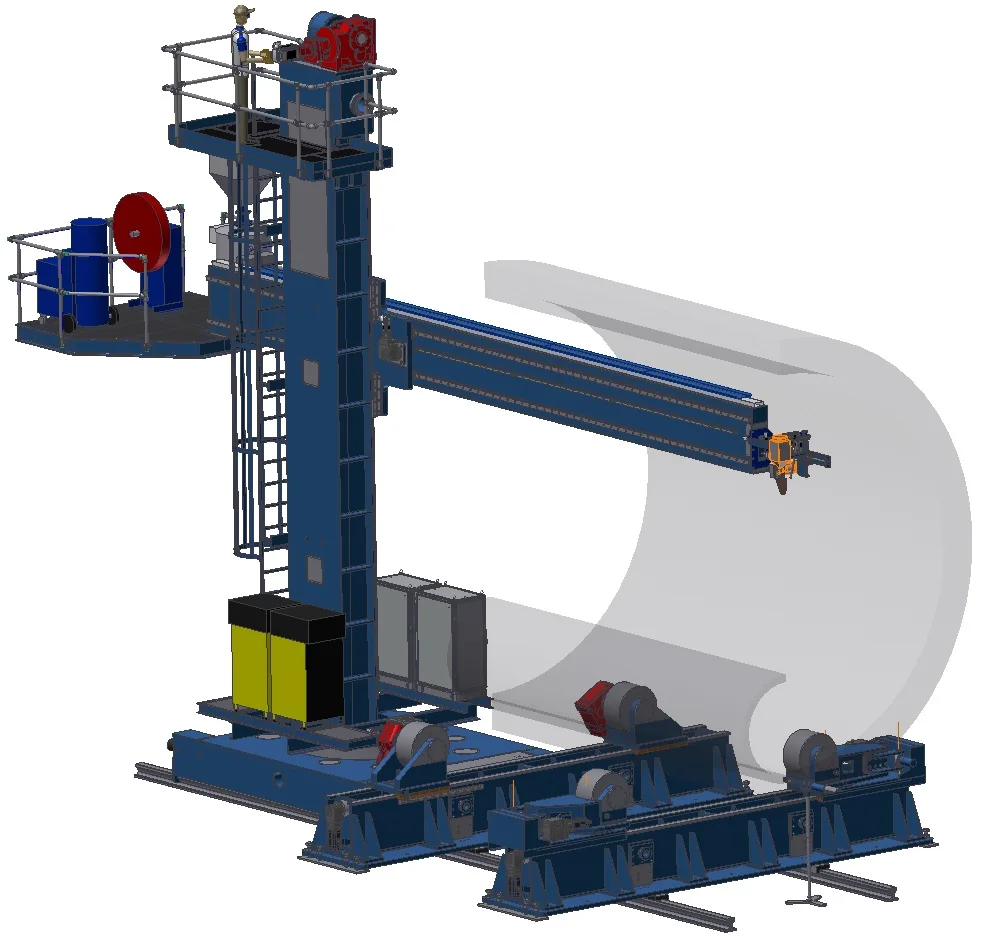

DEUMA Column Boom rotator combined strip cladding Submerged Arc Welding machine

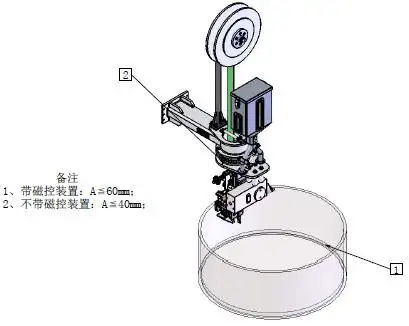

Strip clad welding system consists of strip clad welding head(or equipped with carriage) and welding power source, integrated with manipulator, turning rolls and positioner etc. for complex welding.

DEUMA has been building Column & Booms (Manipulators) for more than 50 years. We are leading manufacturers of manipulator.

Due to their extremely robust welded construction, these Column & Booms (Manipulators) provide the necessary rigidity for vibration-free working. As such they ensure high quality welding or grinding operations. The design concepts and the selection of material of bought-in items are subject to very strict criteria. Drive and guide elements are generously dimensioned. Moving electrical cables are guided in cable chains. The control elements are operator friendly. The Column & Booms (Manipulators) are, in the most, employed to carry-out welding and cutting operation as well as grinding work. Especially for grinding operations the column & booms (manipulators) are designed to be extremely rigid and precise. Manipulators can be equipped with PLC or CNC control, rotary encoders and AC servo drives.

The following options are available:

With foundation base or travelling carriage (track gauge to choice)

Columns stationary or rotating

Rotation drive manual or by motor

Clamping manual or by motor

Boom fixed or adjustable

Operator’s seat, platform or carriage

Mounting of welding, cutting or testing equipment of any make

Control manual, programmable, CNC or DNC

Special attachments

We would be happy to answer your questions personally.

A: We are a MANUFACTURER with import and export rights.

Q: What’s our payment mode?

A: Negotiable, but usually L/C and TT.

Q: Can machines be customized?

A: YES.

Q: Do we offer replacement parts?

A: YES.

Q: How long is the warranty period?

A: One year.

Q: How do we pack goods?

A: The mainframe is naked, while other parts are packed in plywood case.

Q: How long is the lead-time?

A: Usually 90 days.

-

Submerged arc welding machine 4-wheel welding tractor equipped with welding source and flux recovery system

-

MZ-1000 three-phase 380V/415V/440V submerged arc welding equipment tractor

-

Professional welding machine manufacturer manufactures CNC welding machine high performance arc welding machine

-

High Performance 1250A 380V 415V 440V Industrial Submerged Arc Welding Machine

-

High quality IGBT MMA welding machine MZ1250 IGBT inverter automatic submerged arc welding machine

-

Aluminum alloy tuyere arc welding machine welding machine

-

MZ-1000 IGBT INVERTER Submersible ARC Welding Machine

-

MZ-1000 IGBT inverter automatic arc welding machine

-

MZ-1000 automatic gouging machine equipment with control car multi-functional submerged arc welding

-

Single Sided Arc Welding Machine