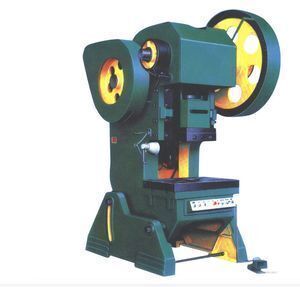

automatic aluminum foil container punching machine J21 sheet metal punch power press machine hole punching machine for steel

-

Supplier: Anhui Pacific Heavy Duty Machine Joint-Stock Co., Ltd. -

Region: Anhui, China -

Contact: Mr Michael Zhang -

Price: $750.00 /set -

Min. Order: 1 set

| Nominal Force: | 160-1000KN; | Stroke length: | 60-130mm; |

| Product name: | Deep-throat Press Machine; | After-sales Service Provided: | Online support,Video technical support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service; |

| Power Source: | Mechanical; | Condition: | New; |

| Advantage: | Easy Operation; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Place of Origin: | Anhui China; | Voltage: | 380v; |

| Item: | Hole Punching Machine; | Brand Name: | Wanli; |

| Material: | Steel Material; | Warranty: | 1 year; |

| Certification: | ISO9001; | Power(W): | 1.5-7.5kw; |

| Keyword: | Iron Sheet Power Press Machine; | Packaging Detail: | automatic aluminum foil container punching machine J21 sheet metal punch power press machine hole punching machine for steel in Plastic Film; |

| Color: | Customizable; | Supply Ability: | 1000 Set/Sets per Month; |

| Port: | Shanghai; | Stroke frequence: | 45-100times/min; |

| Pressure Stroke: | 5-10mm; | Weight: | 1.1T; |

| CNC or Not: | Normal; |

Motor

Power:1.5-7.5kw

Speed:960-1440 turns/min

Manual Slide Adjustment

The press is equipped with a simle and reliable manual slide adjuster with 0.1mm increment indicator.

Easy and safty control

The control panel includes double hand buttons and emergency stop button and foot pedal control switch is optional.

Mechanical overload protected

A safty block is add inside the slide to protect the die if over load, it is easy to change the safty block by opening window in the side.

1. The frame is of all steel construction, fabricated from Rolled steel plates with suitable cross ribbings. Presses up to 30T will be supplied with C.I. legs. proper alignment of the frame is ensured by machining.

2. The clutchis of pin/rolling key-type. the clutch is rigid and well supported. the clutch gives continuous strokes for mass production

3. Crank shaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy

4. Properly sized flywheel, is made of high grade cast iron, for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running

5. Table and fam are made pf high grade heavy duty cast iron & properly seasoned. They are perfectly aligned, to each other to obtain high accuracy & precision press operation

6. Gear are of steel cast or fabricated. Gear teeth are generated by precision hobbing machine.

7. An efficient shot luvrication system has been provided for lubricating the sliding surfaces and moving parts. The lubricant is applied by hand pump

8. Position by spanners within minutes. the press ils so designed that even in maximum inclined position, it is stable under heavy pressing load

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions is caused by customers' incorrect operation, we will provide spare parts at cost price. We can also offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and show operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why choose us :

1. We will the machine for few days, and use your materials to do the test. Only guarantee the machine to show the best performance, and then we will ship it out.

2. our elite teams can provide you professional, customized and all-round services around the dock. If you need any help, please contact us by Whatsapp, Skype, Email or telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working station.

2. Analyze your information and provide our feedback

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products we can offer professional designing.

-

Steel pipe hole square punching hydraulic pipe punching machine

-

Manual license plate embossing machine hand embossing equipment M2/Jiehui

-

APEC punching die-cutting die punching round hole, oval hole

-

Thread punching machine (manufacturer)

-

High Quality Curtain Eyelet Machine Garment DIY Hand Press Riveter Machine

-

0.5T-1.5T force manual operation hand press for cutting bending punching riveting

-

Customized 10-160 tons C-type open-arm punch power press.

-

Automatic eyelet machine/automatic buttonhole machine/automatic eyelet punching machine

-

Wholesale Hand Corn Press Machine For Corn Tools Snap Rivet Corn Hand Press Maquina De Prensa De Ojales

-

Automatic buttonhole press machine flag button making machine flag hole making

Other Products

-

$3250.00 / set

$3250.00 / set -

$3500.00 / set

$3500.00 / set