industrial synthetic diamond powder for resin bond

-

Supplier: Henan Uhd Ultrahard Tools Co., Ltd. -

Region: Henan, China -

Contact: Mr. Will Wang -

Price: $0.05 / >=1000 pieces -

Min. Order: 1000 pieces

| Abrasive Grain Sizes: | 30-70#; | Color: | yellow color; |

| Package Type: | 1.3 layers of plastic bags or bottled then in outer carton 2.according to customer's reques; | Brand Name: | UHD; |

| Name: | synthetic diamond powder; | Application: | Making Polishing Tools; |

| Gross weight per batch: | 0.2 KG; | Size: | Customer Size; |

| Usage: | Cutting and sawing; | Grade: | Top Grade; |

| Model Number: | UHD260; | Selling Units: | Multiple of 100; |

| Shape: | Irregular; | Place of Origin: | Henan China; |

| Product name: | industrial synthetic diamond powder for resin bond; | Type: | Superabrasive; |

| Grit: | MicroFine; | Feature: | Durable; |

| Package size per batch: | 5X5X8 cm; |

industrial synthetic diamond powder for resin bond

Product Show of industrial synthetic diamond powder for resin bond

synthetic diamond powder characteristics: polishing Diamond Powder is made of high quality diamond with high toughness and purity, processed by special milling and shaping techniques, regular and blocky shape.

synthetic diamond powder with perfect shape, regular shape and sharp edge, high transparency, high strength and heat stability ,Suitable for wire saw, band saws and other moderate duty sawing cutting, high quality drill making and electroplated industries.

synthetic diamond powder usage: polishing Diamond Powder is suitable for metal bonded products, ceramic bonded products, electroplated products etc; usually used for machining hard alloys, glass, ceramic, and other stone materials.Metal Bond Diamond Powder, Diamond Powder, diamond polishing powder

More Size of industrial synthetic diamond powder for resin bond

Grit | 30/35 | 35/40 | 40/45 | 45/50 | 50/60 | 60/70 |

UHD280 | * | * | * | * | * | * |

UHD260 | * | * | * | * | * | * |

UHD230 | * | * | * | * | * | * |

UHD210 | * | * | * | * | * | * |

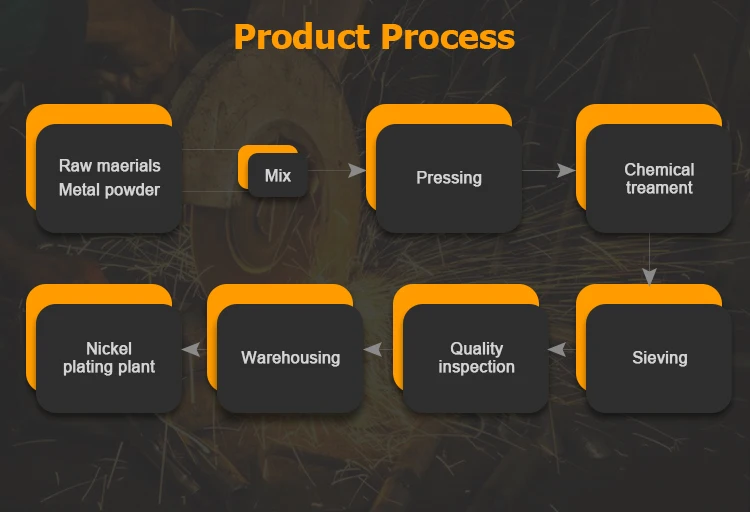

Product Processing of industrial synthetic diamond powder for resin bond

Features of industrial synthetic diamond powder for resin bond:

1. Selection of high-quality diamond as raw material, can ensure high-quality powder;

2. All products through standardized management processes, process-oriented quality testing to ensure high performance and stability of the diamond;

3. Anti-static dust-free workshop production, to ensure product purity 99.9%;

4. Diamond powder particle size range of uniform, crystalline high agreement, basic grains accurate, easy to produce scratches when polishing;.

5. Product in strict accordance with ANSI B74.20-2003 R2010 standards.

If youare interested in our product, please Send Inquiry according to the follows:

-

White corundum F150 JIS#150 Sandblasting for removal of copper plating

-

Honing stone, Honing abrasives

-

RAIZI Tools - Super High Quality Hot Selling 4"/100mm Cilicon Carbide Dry Polishing Sandpaper for Stone

-

Factory price facial cleanser frosted walnut shell powder cosmetics walnut particles frosted particles

-

95% Promotional Price Brown Emery Powder/Alumina Abrasive

-

Pakistan white corundum/white alumina

-

Blind wheel sand disc sand paper grinding wheel angle grinder hardware tool polishing wheel abrasive tool

-

SCS Black Silicon Carbide Cutting Diamond Grinding Tools Grinding Stone Wheel For Granite Quartz Stone Polishing

-

3mm 4mm 5mm 6mm 7mm 8mm lab grown diamond hpht rough yellow diamond for industry and jewelry

-

Yellow Sanding Sponge Backed Hand Sanding Sandpaper

Other Products

-

$0.15 / gram

$0.15 / gram -

$0.06 / piece

$0.06 / piece -

$0.06 / piece

$0.06 / piece