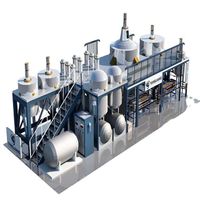

China supplier Continuous waste crude oil distillation equipment

-

Supplier: Shangqiu Jinpeng Industrial Co., Ltd. -

Region: Henan, China -

Contact: Mr Yvonne Niu -

Price: $50000.00 /set -

Min. Order: 1 set

| Supply Ability: | 100 Set/Sets per Month; | Machine Type: | waste tire pyrolysis and distillation plant; |

| Dimension(L*W*H): | 2500*8800mm;2500*11000mm; | Port: | Lianyungang; |

| After-sales Service Provided: | Field installation, commissioning and training; | Warranty: | 1 year; |

| Heating Method: | Hot air; | Voltage: | 380V 3N; |

| Material: | Waste engine oil, fuel oil, crude oil; | Power(W): | 15-25KW; |

| Flow: | 30-300MT; | Structure: | Vertical Type; |

| Weight: | 35-40T; | Place of Origin: | Henan China; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Brand Name: | Jinpeng; |

| Condition: | New; | Cooling Method: | Cycle water; |

| Capacity(24 hours): | 30~300MT; | Operating Mode: | Continuous Operation; |

| Type of Installation: | With Foundation; | Oil Yield: | 80%-90%; |

| Packaging Detail: | In containers; | Certification: | CE, ISO,SGS; |

| Noise dB(A): | ≤85; |

China supplier Continuous waste tire pyrolysis and distillation plant

|

1. Product Pictures of Continuous waste tire pyrolysis and distillation plant

2. Product Description of Continuous waste tire pyrolysis and distillation plant

1. Brief Introduction

Shangqiu Jinpeng Industrial Co., Ltd, as the first domestic professional institute in the recycling of

solid wastes( waste plastics, waste rubber, tyres), is a technology innovate demonstration

enterprise involving scientific research, development, manufacture and sales together.

Founded in 1985, our company has achieved great progress in waste recycling area. Nowadays,

our company has owned 14 national patents and a provincial engineering research center. And

our products has achieved CE, ISO, BV, BV certifications. The emission can meet GB13271-2001

related standards. Our company has developed XY-series environmental protection equipment

with the outstanding advantages of less investment, high efficiency, simple operation,

environmental friendly and so on. Up to now, our products include Pyrolysis Plants for waste

rubber, plastic and tyres, normal pressure waste tire pyrolysis and distillation plants for waste engine oil, crude oil and the

Carbon Black Deep-process Machines.

According to the actual situation in every country and district, we developed series of machine for

crude oil, waste engine oil, tyre oil and plastic oil after pyrolysis that includes about 4 tons and 6

tons capacity daily on batch systems, and the fully continuous distillation systems with daily

capacity from 30~300Mt.

2. Process Description

1> Unique manufacturing and technology with our own formula of our equipment in China.

2> High oil output, about 80%-90%.

3> Good quality end product oil as the substitution of standard diesel oil in usage.

4> Security:

A. Adopting automatic submerged-arc welding technology

B. All of the welding will be detected by the ultrasonic nondestructive testing method to ensure the

welding quality and the welding shape.

C. Equipped with anti-explosive device, safety valves, emergency valves, pressure and

temperature meters, as well as the alarming system.

5> Environmental-friendly:

A. Emission Standard: Adopting special gas scrubbers to remove acid gas and dust from smoke.

B. Smell during operation: Fully enclosed during the operation

C. Water pollution: No pollution at all.

6> Energy conservation and low cost on operation:

Special covers of the reactors and chambers can keep hot during the heating in good efficiency as

well as the direct heating system to save energy and cost.

3. Technical Parameter of Continuous waste tire pyrolysis and distillation plant

No. | Item | Technical Parameter |

1 | Suitable Raw Material | used oil, pyrolysis fuel oil, crude oil |

2 | Structure | Continuous Vertical |

3 | Chamber Material | 16mm Q245R boiled steel |

4 | Daily Capacity (24H) | 30-300MT |

5 | Condensers | Q235R |

6 | Fuels Choice | Oil, gas, coal |

7 | Power | 70kw/h |

8 | Cooling Method | Cycle Water(70M3) |

9 | Delivery Time | 1 month |

10 | Type of Installation | With foundation |

11 | Installation Area (m) | 25m*35m |

12 | Installation & Commissioning Time | About 1 month |

13 | Noise dB(A) | ≤85 |

14 | Operating Mode | Continuous |

15 | Sync Gas Treatment | Fully burned as fuel |

16 | Manpower | 3~4 per shift |

17 | Total weight(MT) | 100mt |

18 | Shipment | 8*40HC |

4. End Product and Percentage

The Oil distillation Plant with oil raw materials without water as example, the output is:

Oil Yield:80%-90% Sync Gas:≈3%

Residue:≈5% Inner Water:≈3%

5. Feasibility Analysis on 15MTD capacity Distillation System

NO. | ITEM | DETAILS |

1 | DAILY CAPACITY | 15MT |

2 | Raw Materials | Crude oil, Tyre oil, plastic oil, used engine oil, etc. |

3 | Cost of raw materials | 15T*4200¥/MT=63,000.00¥ |

4 | #1 Cost of Catalyst | 15MT*0.3%*5000¥/MT=225¥ |

5 | #2 Cost of Catalyst | 15MT*85%*200¥/MT=2,550.00¥ |

6 | Labor (DAILY) | 2P*150¥/D/P*3 shifts/D=900¥ |

7 | Electricity & Water | 1.2¥*40KW/H*24=1,152.00¥ |

8 | FUEL COST | 2MT*1200¥/MT=2,400.00¥ |

9 | Other | 200¥ |

10 | Total Cost | 70,427.00¥ |

11 | Oil Income | 15MT*85%*7000¥/MT= 89,250¥ |

12 | Heavy Oil Income | 15MT*7%*1200¥/MT=1,260.00¥ |

13 | Gross Income | ¥90,510.00 |

14 | Daily Net Income | 90510¥−70427¥=20,083.00¥ |

15 | Monthly Net Income | 20083¥/Batch*22D=441,826.00¥ |

16 | Yearly Net Income | 441826.00¥/M*11M=4,860,086.00¥ |

3. More Products for You to Choose

Company Show Company Show |

1. About us

2. Why Choose

ü Advantages

Less investment in equipment, efficient performance and simple production process are the

biggest advantages of our company. According to the actual situation in every country and district,

we have the capacity of series of machines for disposing scrap tire and plastic in 4 tons, 6 tons,

10 tons, 20tons and 30 tons of different units.

ü Factory Tour

3. Our Service

After-sales Service:

a. We have professional service staff who are responsible for your plants besides our sales

managers and technicians.

b. Engineers available to go overseas for plant installation.

c. Quality warranty period: one year for the main reactor of pyrolysis machines and lifetime

maintenance for completing machines.

4. packing and shipping

Packaging details | 1*40FR and 1*40HQ for 10 tons 2*40 HQ for 5 tons Weight: about 30tons All goods are packed with export standard package to make sure no damage during transportation. |

Detail details | about 30 days after receiving deposit. |

5. Certifications

6. Our Markets

Our products have been sold to Thailand, Malaysia, South Korea, Indonesia, India, Pakistan,

West Africa and Taiwan district, etc.

7. Contact

-

Yangjiang waste oil refining equipment recycling waste motorcycle or automobile oil waste oil regeneration machine

-

Recycling waste oil into diesel oil refinery is highly profitable and low cost

-

China Made Heavy Fuel Oil Distillation Mini Refinery

-

Standard Diesel and Gasoline or Crude Distillation Units in U.S. Crude Oil Refinery

-

2023 NEW Oil filter machine Oil filter equipment manufacturing

-

New continuous oil filter oil recovery machine

-

Factory supply portable oil purifier hydraulic oil filter cart oil purifier unit

-

500kg/day small edible oil refiner crude oil refiner HJ-JLYJ200

-

Distillation Unit Price of Small Crude Oil Refinery

-

New energy TYR waste oil to diesel plant edible oil recovery machine oil filter machine