ZXL-B700 Non Woven Eco Bag Making Machine,Laminated Non Woven Bag Making Machine,PP Nonwoven Bag Making Machine

-

Supplier: Zhejiang Zhengxin Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Keven Chen -

Price: $15000.00 /set -

Min. Order: 1 set

| Condition: | New; | Material: | Non Woven Bag; |

| Supply Ability: | 10 Set/Sets per Month; | Machine Type: | Cutting Machine; |

| PLC: | Taiwan; | Brand Name: | ZHENGXIN; |

| Voltage: | 380V/220V; | Model Number: | ZXL-B700; |

| After-sales Service Provided: | Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service; | Place of Origin: | Zhejiang China; |

| Certification: | CE/ISO; | Dimension(L*W*H): | 7600*1900*2100mm; |

| Warranty: | One Year; | Bag Type: | Fruit Bag; |

| Applicable Industries: | Manufacturing Plant; | Payment Terms: | L/C,T/T; |

| Computerized: | Yes; | Model: | ZXL-B700; |

| Weight: | 2000KG; | Packaging Detail: | export standard packing; |

| Production speed: | 20-120pcs/min; | Port: | Ningbo; |

Model | ZXL-B700 |

Bag Width | 100-800mm |

Bag Height | 200-600mm |

Size of Bag Gusset | 40-160mm |

Material Basis Weight(thickness) | 30-100g/m² |

Production Speed | 20-120pcs/min |

Power Supply | 380/220v |

Total Power | 12kw |

Overall Dimension | 7800*2100*2300mm |

Weight | 2000KG |

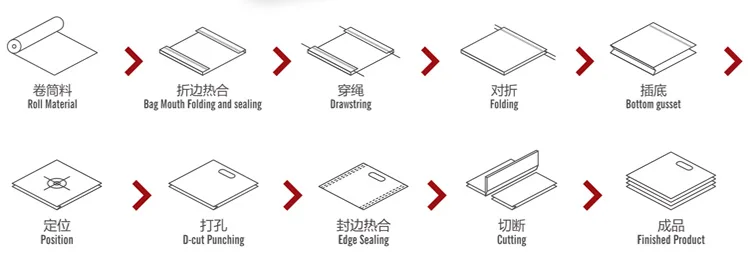

ZXL-B700 non woven flat bag making machine adopts mechanical, electrical, optical and pneumatic integration technology, suitable for non-woven fabric, different specs flat bag, flat bag with D-cut, drawstring bag, bottom gusset bag, bottom gusset bag with D-cut and side gusset bag can be made by this machine.

1). It’s a ideal equipment for producing non-woven flat bag, drawstring bag when you don’t need the handle bag.

2). Adopts top brand electricity, optical and pneumatic components, features reliable, long working life and easy maintenance.

3). All the bags adopts thermal bonding by ultrasonic welding(Taiwan top brand ultrasonic device), features strong sealing effective, high speed, tidy and environmental friendly.

4). With experienced engineers and well-trained technical workers and continuous innovation and reform, ensure our machine’s quality and mechanical stability.

5). Equipped with auto loading device, Taiwan touch screen, computer control, auto feeding, counting and stopping, easy to operate, one or two person can handle it easily.

6) . With CE certification and ISO9001 certification.

| Packaging | |

| Volume | CBM |

| Weight | KG |

| Packaging Details | Before packing, we grease the machine with white oil to make metal parts rustproof and shining forever. |

| The packaging is export standard sea worth and will use PET film for packing or pack it according to customers’ special requests. | |

| Delivery | within 30 days after the payment of deposit. Production lead time 7-30 days. |

1. How long will your engineer reach our factory?

Within one week after everything ready (machine arrival your factory, non woven material, power source, air compressor etc. Prepared)

2. How many days will you finish installing ?

We will finish installation and training within 15 days.

3. What should we charge for your engineer?

You should charge for the cost of our engineer's air tickets, hotel, food, and also their salary 80USD one day per person.

4. How long is your machine's warranty period?

All our machine have one year guarantee for electricity parts and two years guarantee for mechanism, starting from finished installation.

5. How could you do after one year warranty period?

We also can do service for you, but you need pay salary for our technicians 80USD/day for each person.

6. How could you do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

7. Does your engineer understand English?

Our engineers understand a little English. All our engineers have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

8. Can you help us find any engineer in our location?

Of course, we will check and inform you as soon as possible.

9. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finishing installation. In case you have any problem, you can contact our sales at any time. Our engineers will take a solution video according your description.

10. How many workers do we need running those machines?

Except Two for bag making machine, flexo printing, slitting, ultrasonic sewing, hydraulic punching machine only need one person for each.

-

Semi-automatic plastic film vest shopping bag forming machine vest bag plastic bag production line

-

High Quality Plastic Fully Automatic Irregular Shaped PP Bag Making Machine Die Cutting Custom Shape Polyester Film Bag Machine

-

High Speed Food Paper Bag Making Machine Price List

-

Wholesale Eco-Friendly Polypropylene PP Spunbond Non Woven Fabric Bag Making Machine

-

Second-hand eight-side-seal bag-making machine Shanghai Kunrun brand 600-type 8-side-seal bag-making machine

-

2022 New Double Layer T-shirt Shopping Bag Making Machine With Four Lines Biodegradable PE Plastic

-

Walmart thank you plastic pe ldpe hdpe automatic double line degradable shopping bag bag making machine

-

Four line bottom sealing bag cutting machine

-

Heat Sealing Cold Cutting Plastic Garbage Bag Making Machine

-

T-shirt plastic bag punching machine

Other Products

-

$17500.00 / set

$17500.00 / set -

$670.00 / set

$670.00 / set