Sucking type self cleaning water filter

-

Supplier: Peide Water Treatment Equipment Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Hongxia Yang -

Price: $1220.00 /set -

Min. Order: 1 set

| Control method: | Differential pressure,time and manual; | Warranty: | 1 Year; |

| Voltage: | AC220V 380V,50Hz,3PH,CONTROLLER:220V; | Application: | cooling tower,air conditioning,heat exchange,irrigation,lake,sea; |

| Condition: | New; | Backwash time: | 50-90s; |

| Install direction: | vertical or horizontal; | Brand Name: | Peide; |

| Supply Ability: | 20000 Set/Sets per Year; | Voltage: | 220V/380V/Others; |

| Filter degree: | 80-500 Microns; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,paypal; |

| Flow rate: | 15-900T/H; | Certification: | ISO 9001:2008; |

| Screen: | Multi stainless steel mesh + pvc structure; | After-sales Service Provided: | Online support; |

| Port: | Shanghai; | Place of Origin: | Jiangsu China; |

| Packaging Detail: | wooden cases; | Max working pressure: | 1.0Mpa,1.6Mpa; |

| Chamber material: | Carbon steel or stainless steel; |

Sucking type self cleaning water filter

How It Works

The unit consists of two stages of filtration, a coarse pre-filter and a stainless steel fine screen.

The unwanted solids accumulate on the inner surface of the fine screen, building up a filter cake, which filters out even finer particles, creating a pressure differential. Once the pressure drop reaches a preset level, a rinse cycle is activated by the factory supplied control system.

The solids are removed from the fine screen using a spot backwashing method, which aggressively sucks the dirt off the screen, similar to a vacuum cleaner, and are carried to the drain via the rinse valve. The dirt collector rotates, ensuring the entire screen is cleaned each cycle. The process takes a matter of seconds, without interruption of system flow.

Control method

Filter has differential switch and integrator. Once the pressure drop reaches a preset level, a rinse cycle is activated by the PLC controller.

Feature

structure compact

low water consumption

fine filter degree

low pressure drop

Application

1.Chilling water treating: such like cooling tower, water supplement system, air conditioning system, heat exchange system.

2.Raw water treating: such like surface water, lake, sea water, tank water, well to remove grind, sand, algae, organism etc.

3.Cycling industry water: cooling tower, polishing process water, ion exchange water, spraying process water, heat exchange plant, rolling plant, casting plant etc.

4.Irrigation: farm, dip field, golf, lawn etc.

5.Recycle water

Filter degree

Mic um | 100 | 120 | 150 | 200 | 400 | 800 | 1500 | 3000 |

Mesh | 150 | 120 | 100 | 80 | 40 | 20 | 10 | 5 |

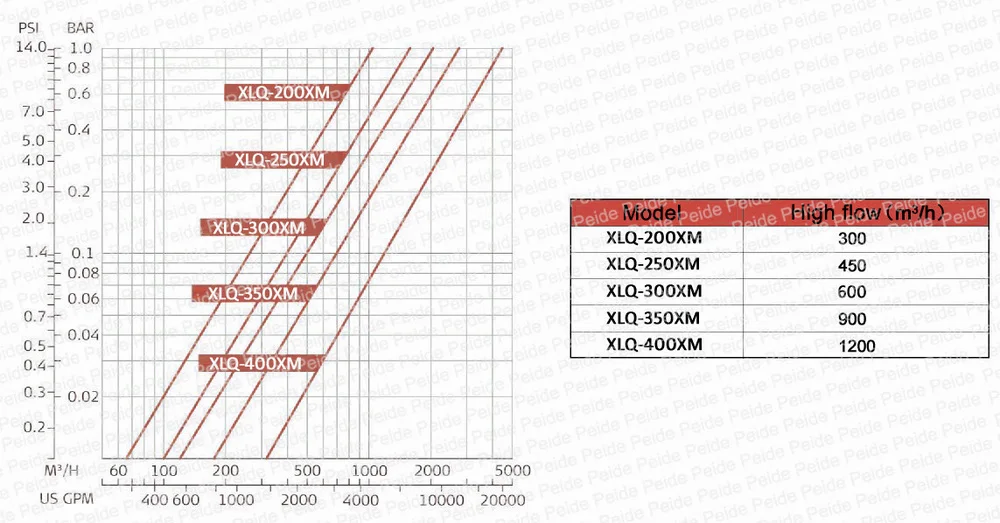

Horizontal type

| Model | Pipe | T/H | Filter area(cm2) | Drain(mm) | Water consumption(L) | Motor(Kw) | Weight(KG) |

| XLQ-50XM | 50 | 20 | 1500 | 50 | 75 | 0.55 | 85 |

| XLQ-80XM | 80 | 50 | 1500 | 50 | 75 | 0.55 | 87 |

| XLQ-100XM | 100 | 80 | 3000 | 50 | 150 | 0.55 | 210 |

| XLQ-125XM | 125 | 100 | 3000 | 50 | 150 | 0.55 | 212 |

| XLQ-150XM | 150 | 150 | 7000 | 50 | 150 | 0.55 | 220 |

| XLQ-200XM | 200 | 300 | 7000 | 50 | 150 | 0.55 | 220 |

| XLQ-250XM | 250 | 450 | 11000 | 80 | 400 | 0.55 | 395 |

| XLQ-300XM | 300 | 600 | 11000 | 80 | 400 | 0.55 | 405 |

| XLQ-350XM | 350 | 900 | 13500 | 80 | 400 | 0.55 | 625 |

| Install way | Horizontal |

| Unit capacity | 15-900T/H,Achieve parallel install to achieve big capacity |

| Min work pressure | 0.25Mpa |

| Max work pressure | 1.0Mpa,1.6Mpa |

| Micron | 80-500um |

| Control way | Differential pressure, time and manual |

| Max temperature | 65℃ (reach to 100℃ if required) |

| Back wash time | 50-90S |

| Rotating speed | 14-20rpm |

| Clean way | Scanning type |

| Differential pressure in cleaning | 0.01-0.08Mpa |

| Back wash water consumption | Approximate 280-310kg |

| Voltage | AC220V 380V,50Hz,3PH,CONTROLLER: 220V |

| Motor power | 0.37Kw |

| Material | Carbon steel with anti-corrosion painting |

| Screen | Multi stainless steel mesh + pvc structure |

| Drain valve | Cast ion with antir-corrosion painting |

| PLC controller | |

Pressure drop VS flow rate

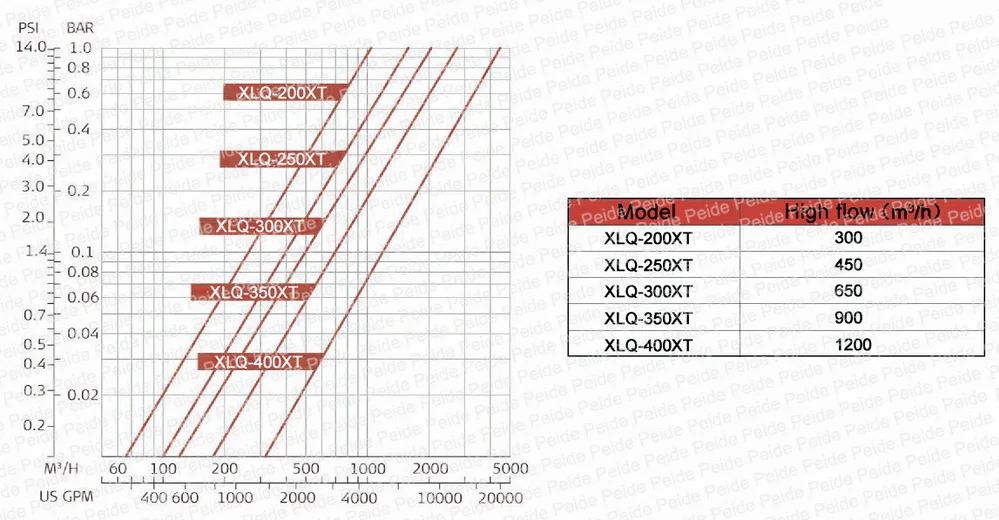

Vertical type

| Model | Pipe | T/H | Filter area(cm2) | Drain(mm) | Water consumption (L) | motor(KW) | weight(KG) |

| XLQ-200XT | 200 | 300 | 7500 | 50 | 250 | 0.55 | 340 |

| XLQ-250XT | 250 | 450 | 11000 | 80 | 400 | 0.55 | 350 |

| XLQ-300XT | 300 | 650 | 11000 | 80 | 400 | 0.55 | 365 |

| XLQ-350XT | 350 | 900 | 13800 | 80 | 400 | 0.55 | 630 |

| XLQ-400XT | 400 | 1200 | 13800 | 80 | 400 | 0.55 | 650 |

| XLQ-350XT | 350 | 1500 | 13800 | 80 | 400 | 0.55 | 690 |

| Install way | Vertical installation |

| Unit capacity | 15-900T/H, Achieve parallel install to achieve big capacity |

| Min work pressure | 0.25Mpa |

| Max work pressure | 1.0Mpa,1.6Mpa |

| Micron | 20-500um |

| Control way | Differential pressure, time and manual |

| Max temperature | 65℃ (reach to 100℃ if required) |

| Back wash time | 60-120S |

| Rotating speed | 14-20rpm |

| Clean way | Scanning type |

| Differential pressure in cleaning | 0.01-0.08Mpa |

| Back wash water consumption | Approximate 500kg |

| Voltage | AC220V 380V,50Hz,3PH,Controller: 220V |

| Motor power | 0.37Kw |

| Material | Carbon steel with anti-corrosion painting |

| Screen | 316SS (Woven, ,multi-layer sintered, wedge) |

| Drain valve | cast ion with antir-corrosion painting |

| PLC controller | |

Pressure drop VS flow rate

Install notice

1.One check valve must be installed at filter outlet. Return pressure and back water is forbidden, in case of screen out of shape.

2.If system wok pressure over 0.8MPa, should install break valve at drain pipe to reduce impact to screen.

3.Notice motor rotating direction. Shut off power immediately once back rotating (anti-clock wise ) occurs. )

4.Installation each part according to arrow direction.

5.Sudden pressure relief at outlet pipe is forbidden. Take normal work pressure 1.3MPa for example, if suddenly open branch valve at outlet, it will occur instant huge different pressure, which damage screen.

6.Make sure filter used under correct work pressure, capacity.

7.If alarms, open by-pass valve for temporary back washing solutions.

8.Make sure control box have constant power supply. If power off, users can open by-pass valve, close in and outlet valve and control box switch.

Installation view

horizontal install

Vertical install

Install requirement

1.Keep space for filter install and maintenance.

2.Drainage pipe length not longer than 20m. Avoid more turns off, keep outlet pipe parallel with ground.

Testing

1.Close inlet outlet valve before testing. Open by-pass valve. Wash dirties staying in pipes.

2.Open inlet valve gradually. Let water into filter till air comes out from filter house.

3.Check leak at joint part, check in/outlet pressure gauge. Connect power when comes to system pressure.

4.Set up drainage time based on system pressure data.

5.Open outlet valve gradually if testing is normal. Close by-pass valve back to normal filtering.

6.Observe several differential pressure changes and drainage. Finish testing if normal.

Notice in using

Equipment can through into operation directly, as already has trial testing. Users can adjust settings based on actual use. Change relay’s program and parameter is forbidden.

1st operation notice

Follow below steps in 1st operation:

Check drainage pipe connection. No up-inclined angle.

Check connection tighten or not.

Check control box in a dry environment.

Connect power cord, green light means normal. Make sure electrical parts is dry. Water is forbidden into control box.

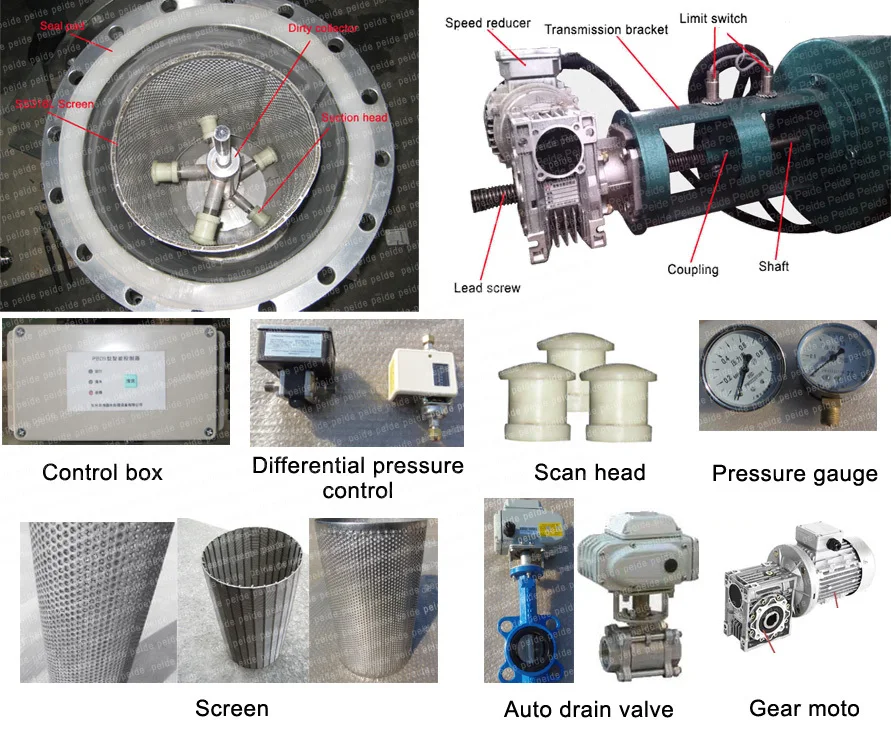

Internal fitting

Manufacturing Process

Customers

Office environment

Certificates

Contact us , you will get more than what you see!

FAQ

Do you have certificates?

Yes , we have ISO / CE certificate and certificate of patent

Do you have design team?

We have a professional design team provide drawings, we wait for your confirmation and production

Can you guarantee delivery time ?

Timely transport, ensure the delivery time

Are you maufacturer ?

Yes, we are the professional water treatment equipment manufacturer in china

-

Tianyu 30-inch PP pleated water treatment filter element

-

Small bottle blowing machine plastic bottle high speed bottle blowing machine from China

-

Magnetic Water Filter Magnetizer Descaler Evp Water Magnetic Water Treatment Device Stainless Steel Zhejiang Wholesale

-

Custom Hydrophilic Polyethersulfone Membrane PES Pleated Cartridge Filter for Distillation

-

Professional Manufacture Cheap Silver Plated Korean Household Dome Ceramic Water Filter

-

Stainless Steel Safety Tri Clamp Filter Housing SS304 SS316L Filter Housing 20'' 30'' 40'' Cartridge Filter Housing

-

Best Selling Sediment Pleated Cartridge Filter End Caps

-

Korea Water Filter Top Sale DEWBELL water filter you can choose and replace Easy to install and replace filter MADE IN KOREA

-

DONJOY Stainless Steel 316L Microfiltration Sanitary Filter with Sampling Valve

-

Sediment polypropylene pp yarn wound water filter element 5 microns 10 20 40 inches

Other Products

-

$1100.00 / set

$1100.00 / set -

$1000.00 / set

$1000.00 / set