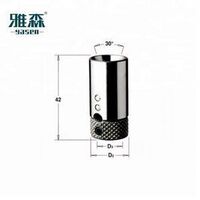

hardwood and laminated board hinge boring bits /forstner bits woodworking

-

Supplier: Mianyang Yasen Hardware Tools Co., Ltd. -

Region: Sichuan, China -

Contact: Ms Sonia Jiang -

Price: $4.60 / >=10 pieces -

Min. Order: 10 pieces

| Place of Origin: | Sichuan China; | Usage: | CNC Milling Woodworking; |

| Delivery Detail: | within 10 days after payment; | Cutting Diameter: | 12-80mm; |

| Supply Ability: | 7000 Piece/Pieces per Day Woodworking; | Shank: | Parallel Shank Woodworking; |

| Packaging Detail: | In plastic box, then in carton(size:330*300*225mm) Woodworking; | Brand Name: | YASEN; |

| Name: | Woodworking Hinge Boring Bits,Twist Drill; | Certification: | TUV; |

| Package: | Plastic box then in carton box; | Cutting Material: | Tungsten Carbide Woodworking; |

| Port: | shanghai ,guangzhou,ningbo or other port; | Packing: | Plastic box then carton box; |

| Shank Material: | 40 Cr; | Model Number: | FT; |

| Color: | Black/orange; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

hardwood and laminated board hinge boring bits woodworking

Woodworking Carbide Drill Bit Features:

- Suitable for drilling wood, PVC and plastic

- Super abrasion, high precision,light cutting and no burrs around hole side

- The edge part formed in one piece by the full automatic digital control Grinder.

- Concentricity of drill is below 0.01mm

- Excellent effect for hard boards such as melamine panels

- Solid Carbide processng wood drill bit makes longer life

- Customer design offered

Application:

- Portable boring machine.

- Automatic boring machine

- Adjustable drill bit for cnc machine center

- For chip free drilling of blind holes in solid wood and wood-based panels

-

- Used on boring machines alone or with chucks for drilling blind holes in solid wood,wood composites,plastic and laminated material.

Raw material:

- Shank is made of Steel 40 Cr.

- Carbide tip are made of high quality tungsten steel which the hardness up to 93.6 HRA

Function:

- CNC processing machine

- electric power tool

- acrylic board,PVC,wood

Customer return maximum

The customer’s success is Yasen’s success, so Yasen will put the interests of customers in the first place and try our best to help our clients achieve competitiveness.

We have the professional team to support the technical assistance and after-sales service.

The international exhibition

Our company attend the international exhition in several countries every year.And our clients all will get the best service from us.

Our factory is located in Mianyang city,Sichuan Province,Chian(Mainland)

And we have workshop of cnc machine to produce our product.

Packing Details :

10 pcs packed in a plastic boxes. All products well packaged in carton box.

Delivery Details :

2-5days delivery guarantee if items are in stock. 5-15 days after the order is confirmed if no items are in stock .

Our company uses the LASER MARKING MACHINE

for labelling the specification and the brand.

- The phenomenon of edge collapse

1,Crossed blade is not sharp and the two crossed blade is unequal-high.

2, Center point of drill and shank concentricity are not meet the criteria.

3,The machine is on the condition of wrong spindle run- out.

4,The board processing (artifact) is on the move.

5,Spindle rotation and cutter speed is not match.

6,The adaptor concentricity is low and other technical data are not up to standard.

- The phenomenon of ellipse

1,The center point and the shank is misalignment,or the center point is not sharp.

2,The artifact is on the move during drilling.

3,Spindle rotation and tool feed speed is not match.

4,The adaptor concentricity is low and other technical data are not up to standard

5,The spindle of boring machine is loose or damaged.

- The phenomenon of smoke or burn

1,The blade edge is not sharp, the drill bit should be replaced.

2,Spiral groove (chip groove) is congestion that will lead to chip removal poorly.

3,Artifact (material) is humidity over limit or the glue quality is not good ( especially the fiber board and plywood )

4,The tool feed speed is not match with the material and the depth.

5,Choosing the suitable drill bit type for processing materials.

CONTACT:

Phone:+86 18148009904

whatsapp:+86 18148009904

Tel::86 816-2406189

Fax:+86 816-2406190

Email: ![]()

-

Vacuum pump accessories factory price VTLF 2.500, VTLF 2.250

-

1922 Phoenix Carver Woodworking Cutter

-

Multi-cut band saw blades for wood

-

LIVTER Carbide forming tool for table trimming Spindle forming tool TCT Wood profile tool for table making

-

Set of 24 pairs of knives and profile cutter heads

-

LIVTER 1 Piece/Set Cabinet Panel Lifting Knife Set for Spindle Machine 23 styles can be customized

-

Cheap price Richauto A11s A11 0501 0504 A15 A12S A18 dsp controller for cnc router

-

160*4*50*4t Good Quality Tct Carbide Knuckle Knife for Wood Cutting

-

Conveyor rollers for Homag Brandt edgebanders

-

LIVTER 150mm Long x 125mm D x 1-1/4 Bore Steel Body Planer/Moulder Head 4-Wing w/ MD HSS Knives Indexiable Shaper Cutterhead

Other Products

-

$1.30 / piece

$1.30 / piece -

$1.20 / piece

$1.20 / piece -

$0.95 / piece

$0.95 / piece -

$3.35 / piece

$3.35 / piece -

$1.30 / piece

$1.30 / piece