HDPE pipe flange flange and expansion machine

-

Supplier: Zhangjiagang Vina Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Parker Xian -

Price: $5500.00 /set -

Min. Order: 1 set

Product details

| Applicable industries: | Manufacturing plants, construction projects, advertising agencies | Product Category: | plastic pipe |

| Power (kW): | number 22 | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Warranty: | 2 years | Processing type: | Pipe expanding machine |

| heating: | electro-thermal | Package preview: | |

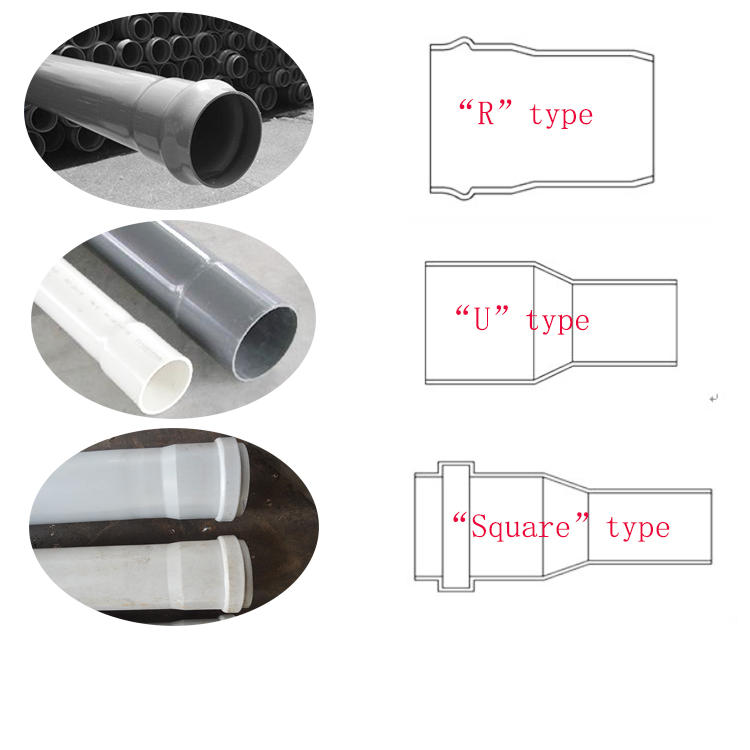

| brand: | Wiener | Flaring type: | "U", "R", "J" type, or customized |

| Mechanical test report: | if | Supply capacity: | 160 sets per year |

| Pipe length: | 200-1000mm | Video outbound inspection: | if |

| Pipe diameter: | 16-1200mm | port: | China Shanghai |

| Main selling points: | automatic | application: | plastic pipe expander |

| Core components: | PLC, bearings, motors, pumps | Health status: | new |

| cooling method: | Air flow cooling or water spray cooling | Voltage: | Customer decides |

| Showroom location: | Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand | Packaging details: | Packed in wooden boxes, fixed with screws at the bottom |

| weight: | 5500 | Core component warranty: | 2 years |

| Dimensions (length*width*height): | 7500*3200*2200 | Place of origin: | Jiangsu, China |

Product Description

feature

The equipment consists of a pneumatic head frame. All mechanical components are made of fully automatic new high-quality steel. The bearings are made of famous brand products. The head frame is composed of a feeding device, a heating furnace and a beating station. The heating furnace is heated by a heating device. Stainless steel heating tube, the heating furnace is equipped with its own unique temperature control system. The heater of the heating furnace adopts a motor rotation structure, so that the tube can rotate left and right when heating. To achieve uniform heating of the pipe expansion surface. The control system of the heating furnace is controlled by an intelligent temperature controller. The device is mainly controlled by a touch screen, and the entire action of the expansion cycle is controlled by a PLC controller.

The equipment consists of a pneumatic head frame. All mechanical components are made of fully automatic new high-quality steel. The bearings are made of famous brand products. The head frame is composed of a feeding device, a heating furnace and a beating station. The heating furnace is heated by a heating device. Stainless steel heating tube, the heating furnace is equipped with its own unique temperature control system. The heater of the heating furnace adopts a motor rotation structure, so that the tube can rotate left and right when heating. To achieve uniform heating of the pipe expansion surface. The control system of the heating furnace is controlled by an intelligent temperature controller. The device is mainly controlled by a touch screen, and the entire action of the expansion cycle is controlled by a PLC controller.

Expansion action flow chartAutomatic and rapid pipe feeding-→pipe fitting displacement-→heating-→pipe fitting displacement- →Expansion molding-→cooling-→finished product

Model | SGK-75 | SGK-160 | SGK-250 | SGK-315 | SGK-630 | ||||

Pipe diameter (mm) | 16-75 | 50-160 | 63-250 | 110-315 | 315-630 | ||||

Total power (kW) | 5.5 | 6.7 | 9 | 12 | 18 | ||||

Output (pieces/hour) | 2-40 | 2-40 | 2-40 | 2-30 | 2-30 | ||||

Flared type | R, U, square | R, U, square | R, U, square | R, U, square | R, U, square | ||||

Pipe length (meters) | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | ||||

Pipe wall thickness (mm) | ≥3 | ≥3 | ≥3 | ≥3 | ≥3 | ||||

cooling method | water cooling or air cooling | ||||||||

detailed image

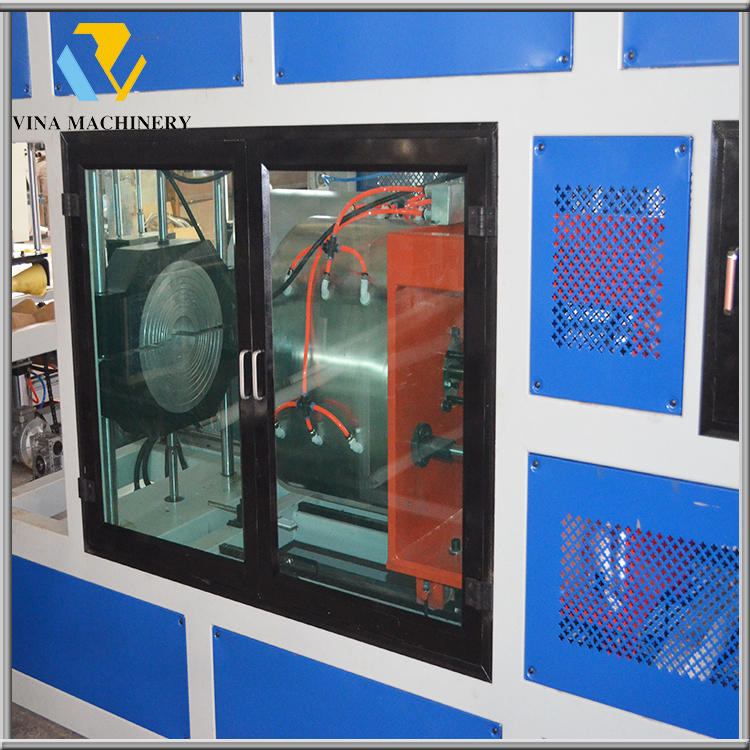

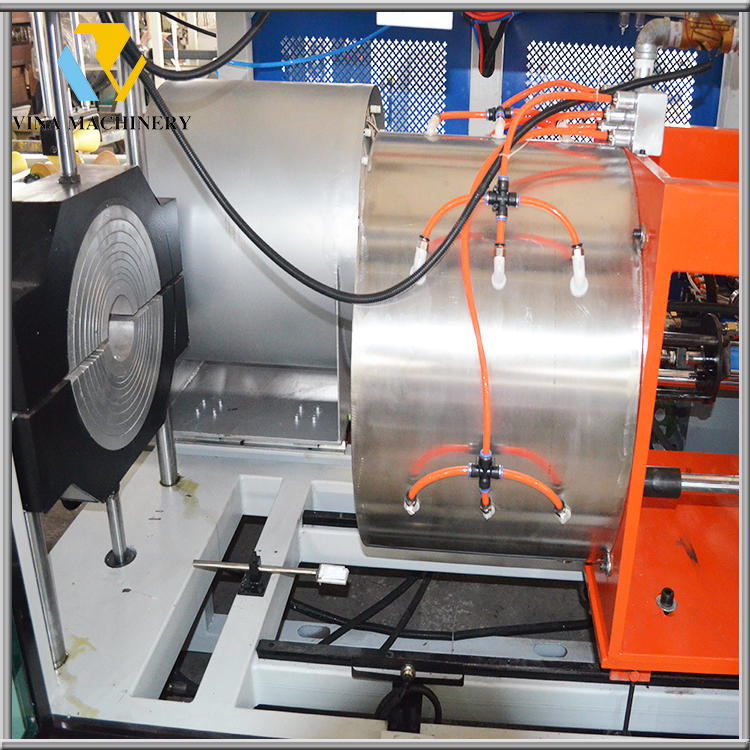

Heating furnace:

There can be one heating furnace or two.The heating furnace uses heating tubes for heating, and the heating tubes have their own temperature control systems to achieve uniform heating of the pipe's diameter expansion surface.

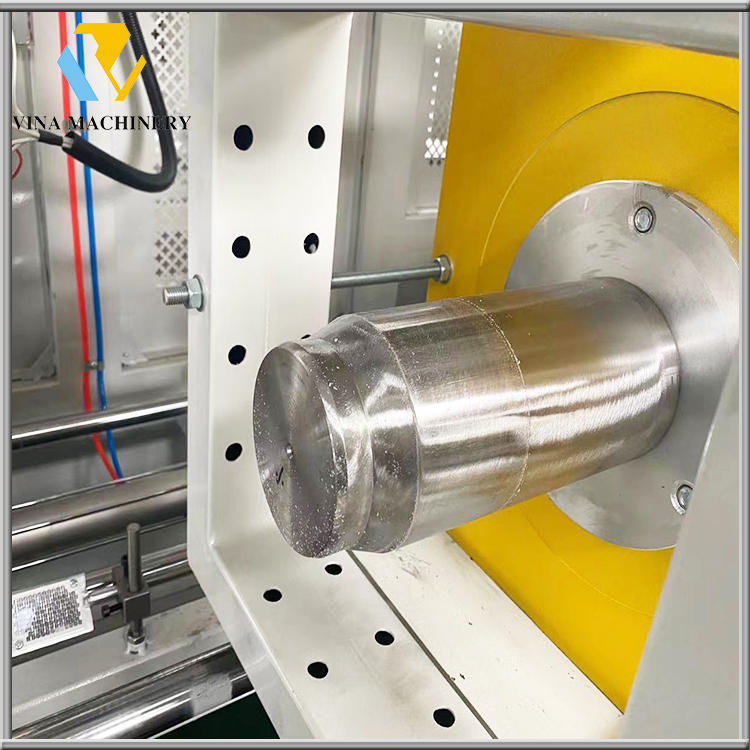

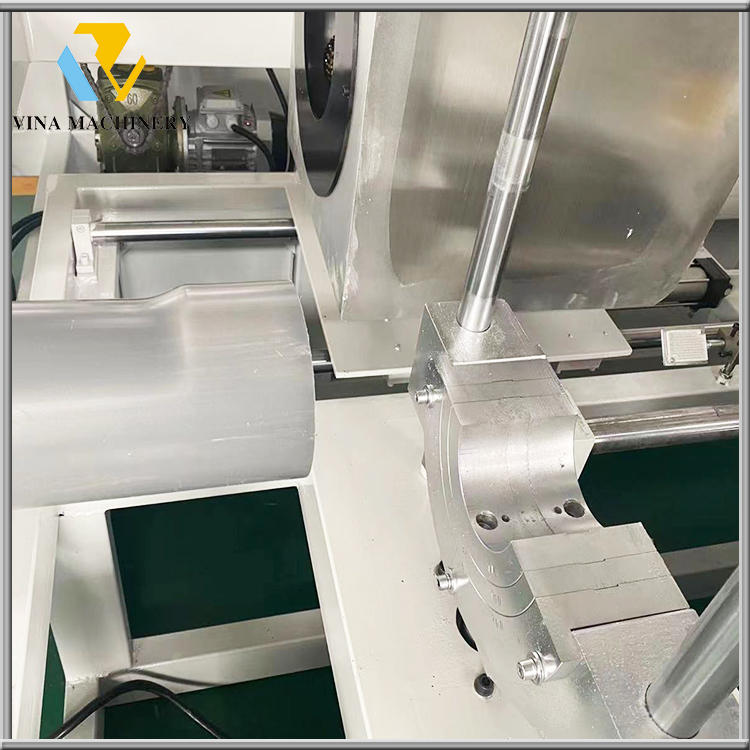

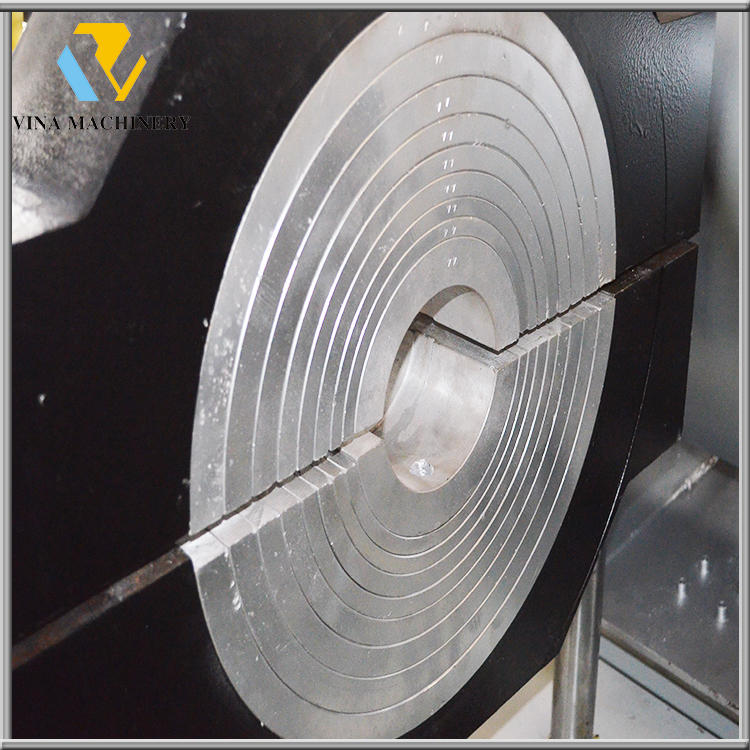

clamp:

Aluminum block clamp. Replace the corresponding clamps according to different pipe diameters, which are easy to replace and have a long service life.

Mold:

The flaring mold can be used for straight flaring and R flaring of plastic pipes. The mold comes with its own oil cylinder. The mold adopts wire cutting, which has high precision and smooth movement. Hard chrome plating on mold surface

various structures

VIEW MORE

You may like

-

Cheaper PVC pipe expanding machine in 2022

-

PVC pipe socket machine/manual expanding machine is suitable for 20-110mm PVC plastic pipe/manual pipe expanding machine

-

Fully automatic PVC plastic drainage pipe flaring making machine pvc pipe manufacturing factory cost

-

Hot selling pipe expanding machine

-

U-type R-type PVC solid wall pipe PVC PE double-wall corrugated pipe two oven automatic PVC pipe expansion and expansion machine

-

Fully Automatic PVC Pipe Flaring Machine/PVC R or U or Rectangular Socket Tube Making Machine

-

PVC plastic pipe flaring/flaring/socketing machine

-

Hot sale high quality oem pvc pipe flare making machine with best price extrusion line

-

Plastic Pipe Manual Flaring Machine PP PE PVC Pipe Flaring Machine

-

Plastic Pipe Flaring MachinePVC Pipe Flaring Machine

Related Search

hdpe pipe fitting butt fusion welding machine

manual hdpe pipe welding machine

hdpe pipe manual butt fusion machine

hdpe pipe making machine

hdpe pipe making machines

hdpe pipe electrofusion welding machine

hdpe pipe fitting electrofusion welding machine

hdpe pipe machine

hdpe pipe machine plastic machine

welding machine hdpe pipe