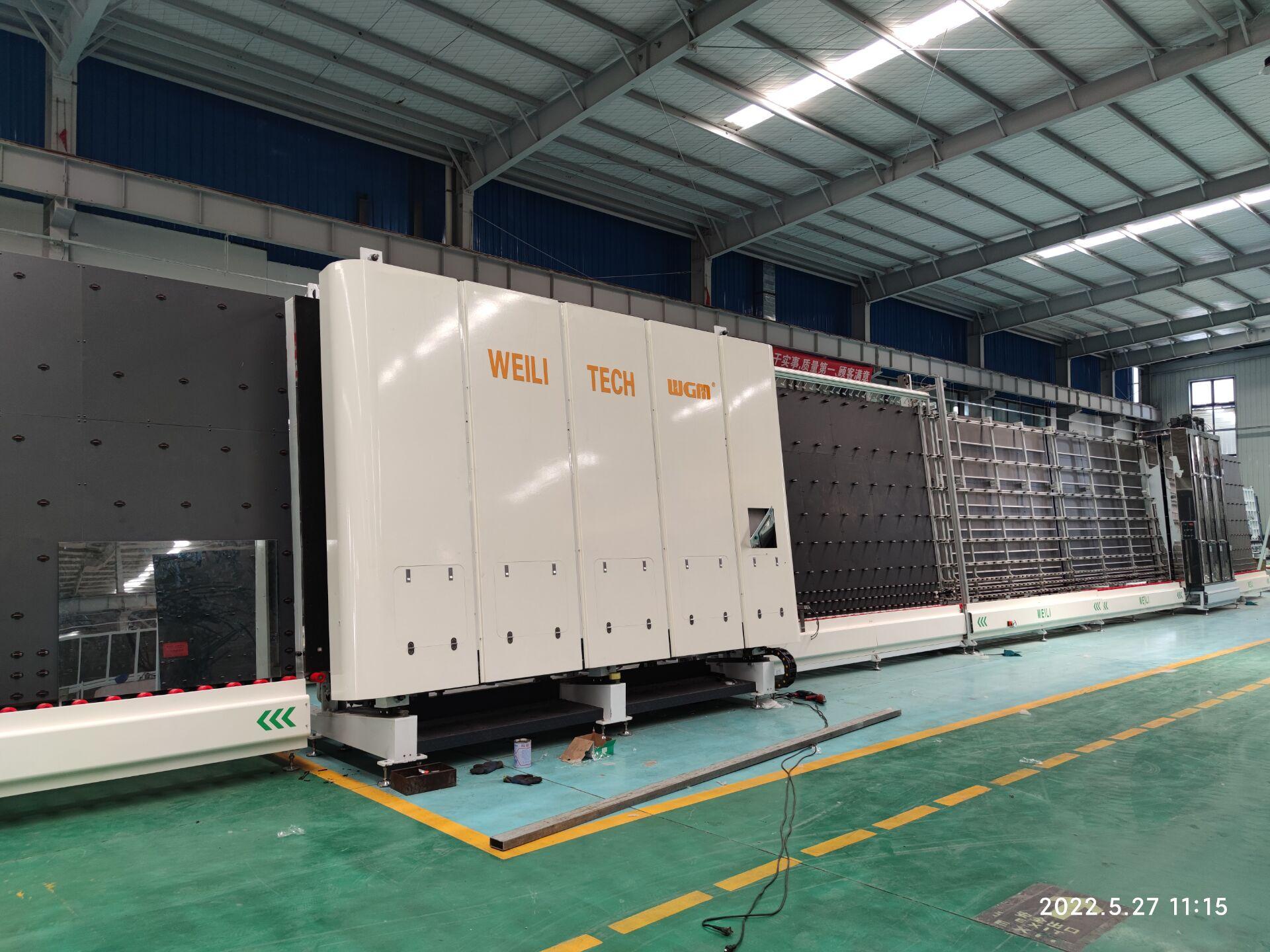

CE/UL insulating glass making machine double-layer glass machine insulating glass production line

-

Supplier: Jinan Weili Machine Co., Ltd. -

Region: Shandong, China -

Contact: Ms Weili Zhang -

Price: $52900.00 / 1 - 1 sets

$46500.00 / 2 - 2 sets

$40900.00 / >=3 sets -

Min. Order: 1 set

Product details

| Cleaning glass thickness: | 3-15mm (optional) | weight: | 5500kg |

| Main selling points: | High productivity | strength: | 3750W |

| Health status: | new | Core component warranty: | 1 year |

| Production capacity: | 600 - 700 pieces | color: | White or customized |

| maximum. Glass size: | 2500x3500mm | Marketing type: | New products for 2022 |

| Insulating glass thickness: | ≤60mm (can be customized) | port: | Qingdao Port |

| Certification: | CE, ISO, UL (optional) | Applicable industries: | Machine repair shops, construction projects |

| Dimensions (length*width*height): | 21600x800x3450mm | Package preview: | |

| Compressed air: | 800 liters/minute | payment terms: | Letter of credit, wire transfer |

| Showroom location: | Turkey, Germany, Vietnam, India, Russia, South Korea, Chile, Australia | Place of origin: | Shandong Province, China |

| Warranty: | 1 year | Core components: | Programmable controller, motor |

| Transmitted glass speed: | 0-45m/minute | Supply capacity: | 10 groups per week |

| Video outbound inspection: | if | Glass cleaning speed: | 2-12m/minute |

| Voltage: | 380V, 50HZ (customized) | Packaging details: | 1. The machine packs necessary parts with plastic film and plywood pallets. 2. Packed in wooden boxes according to customer requirements. |

| air pressure: | 0.5-1.0Mpa | Mechanical test report: | if |

| brand: | WGM & Weili | minute. Glass size: | 300x400mm |

Product Description

working direction | Orient device, right to left (optional) |

color | WEILI design (milky white) |

power supply | 380V/50HZ, 37.5KW |

Dimensions (length x width x height) | 29600×3000×3350mm |

Production quantity | 700-800IG unit/8 hours |

Maximum glass size | 2500x3500mm |

Minimum glass size | 400x400mm |

Cleaning glass thickness | 3-15mm |

Glass cleaning speed | 2-12m/minute |

Insulating glass thickness | ≤60mm |

Transmitted glass speed | 0-45m/minute |

Compressed air: | 800 liters/minute |

air pressure: | 0.5-1.0Mpa,1.2m3/min |

water supply | Circulating water 0.5 tons/day, conductivity ≤40μS |

The insulating glass production line is divided into seven sections, which can realize automatic external splicing, automatic internal splicing, automatic inflating, double-layer insulating glass, triple-layer insulating glass, laminated insulating glass, louver insulating glass, decorative strip insulating glass, and LOW-E coated insulating glass. and stepped insulating glass.

2. LOW-E glass automatic identification system: identifies whether coated glass.

3. Three pairs of high-temperature nylon brushes are driven by six asynchronous motors, which are movable and can automatically adjust the distance according to the thickness of the glass.

4. SKF oil-free lubricated and waterproof bearings prevent oil molecules from contaminating the glass after cleaning.

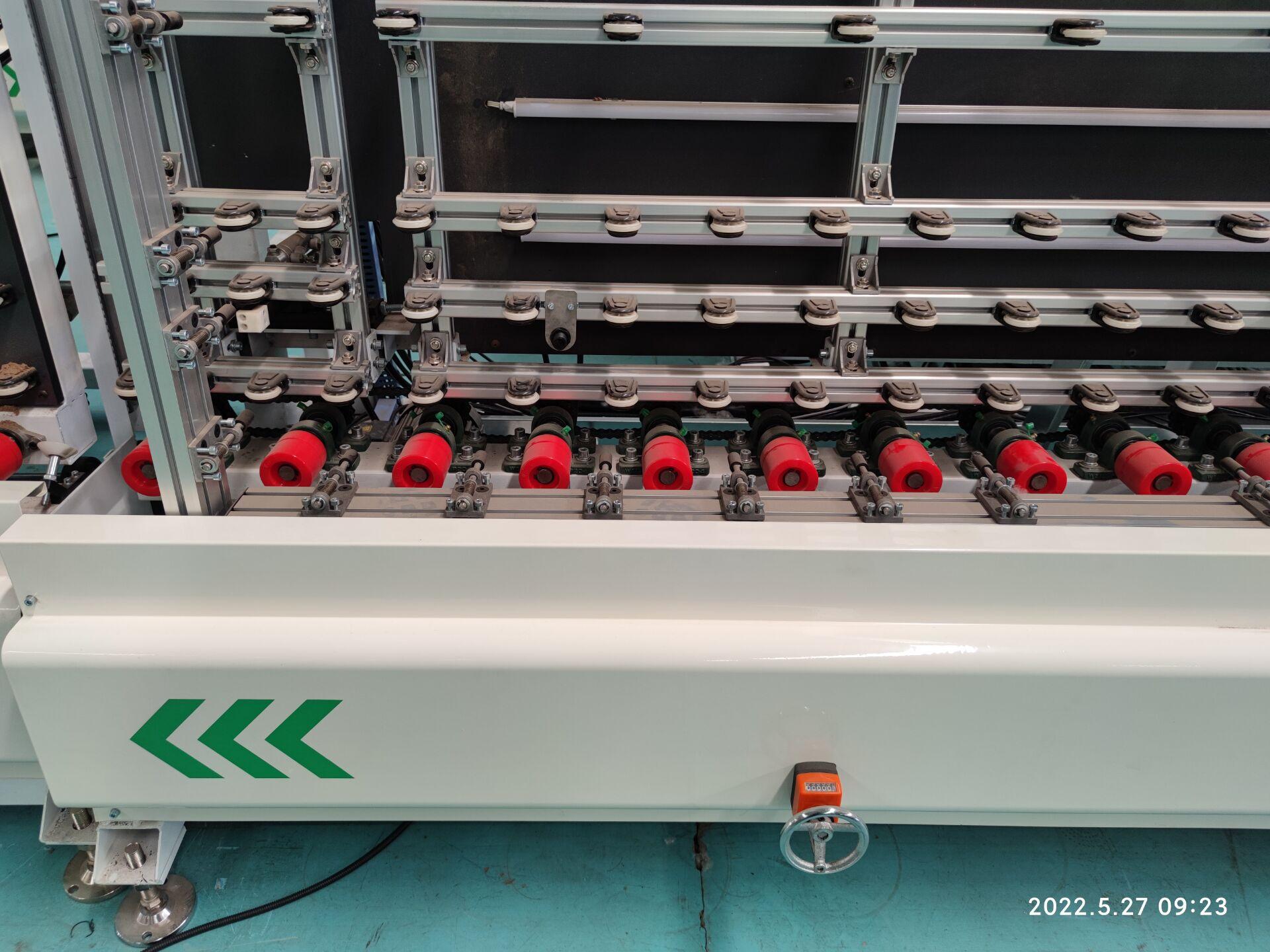

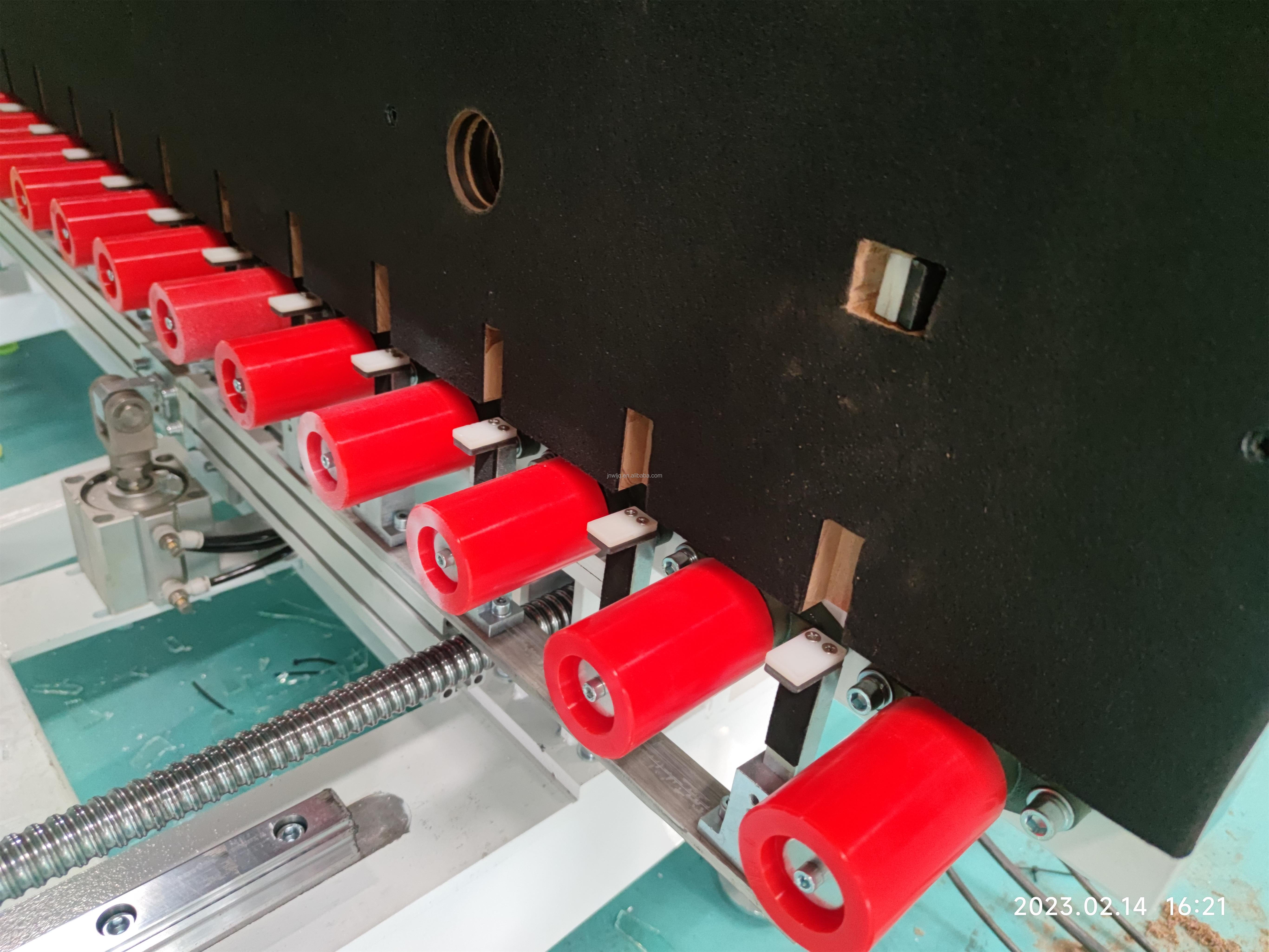

5. Use acid-, alkali-, and corrosion-resistant solid conveyor wheels. The wheelbase can be adjusted according to the thickness of the glass.

6. The glass drying section is equipped with an inclined diamond-shaped air knife and adopts CNC bending technology. Internal circulation air duct prevents wind pollution and saves energy.

7. Adjust the position of the positioning device by turning the digital device, which is simple and convenient.

8. External assembly part: hydraulic power, smoother movement. The positioning frame is driven up and down by a variable frequency motor to automatically detect the height of the glass.

9. The pressing and inflating parts are controlled by PLC, driven by servo motors, and ball screws realize the assembly of double-layer glass and triple-layer glass. The gas filling concentration can reach 90%-98%.

10.The inflation pressure part can be opened for inspection and maintenance. There is a lifting device to avoid misalignment of two or three pieces of glass, especially large glass. Equipped with linear guide rails to ensure high parallelism of the glass press.

Electrical components | ||||

Electrical parts | brand | nation | ||

PLC | Schneider | France | ||

10.0-inch touch screen | Schneider | France | ||

Photoelectric switch | Autonics | South Korea | ||

limit switch | Autonics | South Korea | ||

sensor | Schneider | France | ||

Low voltage electrical components | Schneider | France | ||

Vacuum generator and suction cup | SMC | Japan | ||

Low voltage electrical components | AirTAC | Taiwan | ||

The electromagnetic valve | AirTAC | Taiwan | ||

cylinder | AirTAC | Taiwan | ||

Linear Guides | Silver | Taiwan | ||

Cleaning department bearings | SKF | Sweden | ||

Highlights

The pressing part adopts servo motor, ball screw and guide rail structure. It has 24 inflation hole sectors that can be inflated according to the length of the IG unit.

New design for the input section. The spherical rear wheel reduces the contact area with the glass panel surface. Equipped with LOW-E glass automatic diagnosis system.

Washing section

This part has three pairs of brushes. The brushes are driven by three synchronous motors respectively, and the movement is smooth. The brush is made of high temperature resistant, soft natural bristles, which fully guarantees that it will not damage the coated glass, especially the LOW-E glass layer.

Drying section

Air enters the air knife from the top. The air knife can be opened automatically according to the thickness of the glass. The air knife adopts a reasonable and efficient structural design to improve drying speed and productivity. The new transmission structure is smoother and more stable.

Automatic argon filling with high precision and high filling efficiencyDouble glazing, triple glazing, shaped glass and stepped glass. High pressure and low pressure work together to complete filling in a short time3-10 seconds. Argon filling concentration always reaches above 90%.

VIEW MORE

You may like

-

Production line of glass insulators

-

CE certification and new status insulating glass machine/double glazing machine/insulating glass production line

-

CNC Glass Cutting Machine Float Glass Cutting Machine Multifunctional Glass Cutting Machine

-

Sealant Sealer / Sealant Extruder

-

Glass Bottle Making Machine Production Line 2020 China Glass Bottle Furnace / Glass Bottle Furnace Production Line Project "This in Hand"

-

Glass Grinding Machine Glass Grinding Polishing Machine Portable Glass Edge Grinding Polishing Machine

-

SY-1000 single side horizontal glass edging machine

-

glass production line

-

beer bottle production line

-

CNC four-sided glass grinder

Related Search

float glass production line

vibrating screen machine in sand production line feeding

double layer terrazzo tile making machine

mobile tempered glass making machine

disposable paper tea glass making machine

glass making machine

glass sheets making machine

double line nail making machine

double compressor fried ice roll making machine

glass bottle making machine