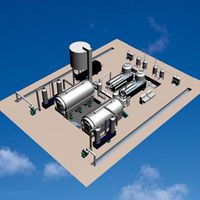

Small integrated scrap aluminum and plastic pyrolysis plant provides fuel for machines

-

Supplier: Shangqiu Yueda Environmental Technology Ltd. -

Region: Henan, China -

Contact: Ms Mia song -

Price: $30000.00 /set -

Min. Order: 1 set

Product details

| Video shipment inspection: | if | Origin: | Henan, China |

| After-sales service: | Free engineers to come to install and debug | Package preview: | |

| Function: | oil extraction from solid waste | Machine test: | X-way and stress testing |

| Marketing Type: | 2019 Hot Products | Packaging Details: | 2* 40HQ 5T mobile waste tire pyrolysis equipment: |

| Main selling points: | high security level | Running type: | semi-continuous |

| Applicable industries: | manufacturing plant | Health status: | new |

| Equipment capacity: | 15-18 tons/day | Finished product: | fuel steel carbon back |

| brand: | Yueda | Heating fuel: | Pyrolysis oil, natural gas, coal |

| Coverage area: | 35M*15M*1O* | Warranty: | 2 years |

| output: | 40-45% fuel oil | Weight (kg): | 39000 kg |

| Reactor Thickness: | 20mm | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Supply capacity: | 200 sets per year |

| Core component warranty: | 2 years | Showroom location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile , UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Japan, Malaysia, Australia |

| port: | Lianyungang port, Shanghai port, Guangzhou port Any big port in China | Mechanical test report: | if |

| Main parts material: | Q345R. Cr12 alloy steel. Stainless steel |

Product Description

Final product after pyrolysis

thing | percentage | usage | ||

fuel oil | 40-45% | 1. Used as fuel for steel plants, chemical industry and other industries industry or hotels and restaurants. 2. Used for heavy oil generator set to take power 3. For distillation. | ||

Coarse carbon black | 35% | 1. Used for building bricks or made into briquettes; 2. Deep processing into N330, N660, N774 or colored carbon black. | ||

steel | 12-15% | sale or reprocessing | ||

synchronous gas | about 5% | 1. Recycled as fuel during processing. 2. Compressed into liquid gas, used as fuel or power generation | ||

Our advantage

advantage Semi-continuous pyrolysis device

1. Security:

A. Using automatic submerged arc welding technology, all welding will

Ultrasonic non-destructive testing method is used for testing.

B. Adopt manufacturing process control system in quality, each manufacturing

Process, production date, operator, etc.

C. Manual and automatic safety devices include: explosion-proof devices, safety valves,

Emergency valves, pressure and temperature gauges, and alarm system.

2. Environmental protection:

A. Emission standard: synchronous gas recovery system: complete combustion after recovery

Utilization, save fuel, prevent pollution. National patent flue gas scrubber: water film

Flue gas scrubber, efficiently removes acid gas and dust in flue gas, environmental protection

Meet relevant national standards.

B. Odor during operation: Fully enclosed during operation

C. Water pollution: During operation, the water we use is recycled water for cooling

Gas oil is converted into liquid oil in the condenser. No pollution at all.

3. National patent,Unique heat insulation shell: efficient heat preservation, excellent

energy saving effect.

4. Semi-continuous operation, less manpower, low operating loss.

5. Unique horizontal design, High oil yield, about 90% oil yield, 100% conversion rate,

Very effective and profitable.

1. Security:

A. Using automatic submerged arc welding technology, all welding will

Ultrasonic non-destructive testing method is used for testing.

B. Adopt manufacturing process control system in quality, each manufacturing

Process, production date, operator, etc.

C. Manual and automatic safety devices include: explosion-proof devices, safety valves,

Emergency valves, pressure and temperature gauges, and alarm system.

2. Environmental protection:

A. Emission standard: synchronous gas recovery system: complete combustion after recovery

Utilization, save fuel, prevent pollution. National patent flue gas scrubber: water film

Flue gas scrubber, efficiently removes acid gas and dust in flue gas, environmental protection

Meet relevant national standards.

B. Odor during operation: Fully enclosed during operation

C. Water pollution: During operation, the water we use is recycled water for cooling

Gas oil is converted into liquid oil in the condenser. No pollution at all.

3. National patent,Unique heat insulation shell: efficient heat preservation, excellent

energy saving effect.

4. Semi-continuous operation, less manpower, low operating loss.

5. Unique horizontal design, High oil yield, about 90% oil yield, 100% conversion rate,

Very effective and profitable.

our service

pre-sale service:

The wide product range enables us to offer our customers machines or complete

processing plant.

Based on the client's requirements and budget, our experts develop efficient and reliable solutions.

According to the customer's order, we strictly produce, what's more, before each order

Customers have the opportunity to visit RESEM working machines or complete factories on site.

After-sales service:

a. We have professional service personnel who take care of your factory besides our sales

Managers and technical staff.

b. Engineers can go overseas for factory installation.

c. Warranty period: one year for the main reactor of the pyrolysis machine, and a lifetime

Machine maintenance

Project cases

VIEW MORE

You may like

-

Newly designed waste oil-to-diesel refinery

-

Fully Automatic Plastic Recycling Pyrolysis Diesel Tire Fuel Plant

-

Beston Group does not need to install a small pyrolysis machine for batch pyrolysis of 1-3T/D plastic tire oil sludge

-

Waste Tire Pyrolysis Diesel Plant Machine Manufacturer 5 Ton

-

Automatic control machine for biomass waste plastic tire pyrolysis machine

-

profitable small pyrolysis machine mini pryolysis plant

-

Small batch waste tire/plastic/MSW pyrolysis plant to convert solid waste into fuel oil pyrolysis machine 1-2 tons

-

New Design to Recycle Scrap Tires into Diesel with 50ppm Sulfur

-

CE certified 15-50 tons automatic plastic pyrolysis plant continuous waste tire pyrolysis system

-

Fully continuous pyrolysis machine 20 tons of plastic waste in fuel oil processing plant

Other Products

-

$58000.00 / set

$58000.00 / set -

$51000.00 - $56800.00 / set

$51000.00 - $56800.00 / set

Related Search

mini waste plastic pyrolysis plant

plastic pyrolysis plant

plastic pyrolysis plant india

tire and plastic recycling plant

aluminum and metal scrap suppliers

plastic pyrolysis recycling oil plant

small plastic pet plant

plastic and tire pyrolysis

aluminum radiator and plastic tank suppliers

pyrolysis pyrolysis plastic oil plant