Energy saving brass workpiece welding induction brazing heater 15KW

-

Supplier: Foshan Sinfor Electro-Machanical Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Kate Choi -

Price: $100.00 /set -

Min. Order: 1 set

| Supply capacity: | 10000 sets per year | application: | Hot forging, brazing, heating, quenching, melting |

| port: | Guangzhou | Health status: | new |

| type: | band heater | Oscillation frequency: | 100-400khz |

| Protection point: | 40 degrees room temperature | payment terms: | L/C, T/T, Western Union, MoneyGram |

| model: | SF-25A | weight: | 28 kg |

| After-sales service provided: | Engineers available to service machinery overseas | Shipping Details: | 7 days |

| Voltage: | 12-480v/(50/60HZ) | Certification: | ISO9001 |

| Warranty: | 1 year | Duty cycle: | 100% full load, 24 hours continuous work |

| Input Current: | 25A | brand: | new information |

| Packaging Details: | Wooden packing | Origin: | Guangdong, China |

| strength: | 15KW | Energy source: | electrical |

| Dimensions (L*W*H): | 570*225*470mm |

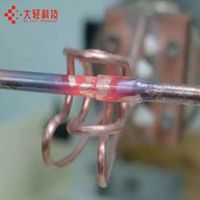

Induction heating machine:

Induction heating equipment is widely used in heat treatment of hardware tools, brazing of various hardware, quenching of mechanical parts and automobile and motorcycle accessories, annealing and demagnetization of stainless steel, hot punching and pushing elbows, some special local heating, metal and alloy melting, etc.

According to different parts, local heating, inner hole heating, or overall heating, surface heat treatment or overall diathermy can be used, and the maximum temperature can reach 1500-2500 °C.

main application:

Large metal parts/bar/rod heating, quenching, hardening, annealing, tempering, normalizing, copper brazing, silver brazing, etc.

Heat treatment of various metal materials:

Quenching/hardening of large shafts, gears, standard bolts/rods/nuts

surface hardening

Layer thickness about 2~3mm

Features:

1. Adopt IGBT power module, low power consumption, high efficiency and energy saving.

2. Adopt soft switch parallel resonance, PFM dual control circuit, easy to operate.

3. The output transformer can not only match the load impedance conveniently, but also isolate the high-voltage power grid; the operation is safe.

4. The circuit is simple and reliable, and it is convenient to carry high power capacity in parallel.

5. 100% full power design, all-weather operation.

6. Very small size, which can save production space for customers.

7. It is suitable for beating, forging and smelting of various metals, especially for the heat penetration of small workpieces that require local heat penetration.

Classification of induction heating equipment:

1. Intermediate frequency: 500HZ-20KHZ. Suitable for diathermy and smelting;

2. Ultrasonic frequency: 10KHZ-100KHZ. Wide range of applications, such as diathermy, smelting, heat treatment, etc.;

3. High frequency: 50KHZ-1MHZ. Suitable for heat treatment and heating of delicate workpieces.

4. Ultra-high frequency: above 500KHZ. Suitable for heating and heat treatment of workpieces.

| (length) * (width) * (height) 570*225*470mm | |

| | |

| | |

* Inquiry and consultation support.

* Sample testing support.

* Check out our factory.

* Training how to install the machine, training how to use the machine.

* Engineers are available to service machinery overseas.

-

Cast brass/copper heater

-

SFM Min 12v 24v 36v 48v 3D printer electric heating tube cartridge heater

-

220v 2500w plastic extruder heater electric mica heating tape

-

Manufacturer of metal coil induction electric heating systems

-

Electric Quartz Radiant Heater Custom Size White Quartz Heater

-

Industrial electric furnace induction heating coil

-

Straight Stainless Steel Tube Heaters for Ovens

-

12-48V 2500W ZVS Induction Heating Module Board High Frequency Durable Professional PCB Board Replacement

-

5-12V 120W Induction Hot Plate Flyback Driver Heater DIY Cooker + Ignition Coil

-

Fan/pig heating equipment for industrial poultry heating

Other Products

-

$999.00 / set

$999.00 / set