plastic molding XLPE powder for plastic shuttle rotomoulding machine plastic fuel tank

-

Supplier: Qingdao Sunsoar Tech. Co., Ltd. -

Region: Shandong, China -

Contact: Ms. Sunshine Yu -

Price: $3.00 / >=20 kilograms -

Min. Order: 20 kilograms

Product details

| Supply Ability: | 10000 Ton/Tons per Year; | Brand Name: | SUNSOAR; |

| Payment Terms: | L/C,T/T,Western Union; | Color: | Natural /Black/Customized; |

| Form: | Pellet/Powder; | Packaging Detail: | Standard Packaging; |

| After-sales Service Provided: | No after-sales service,Video technical support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support; | Condition: | New; |

| Place of Origin: | Shandong China (Mainland); | Processing Methods: | Rotational Molding; |

| Warranty: | 1 Year; | Name: | Rotational Molding Machine; |

| Port: | qingdao; |

Product Description

Sunsoar XLHI-1006 is a crosslinkable high denstiy polyethylene specifically for rotational moulding.

This grade is particularly suitable for use in applications requiring exceptional impact resistance at low temperature and high temperature, toughness and excellent ESCR such as fuel tanks.

The original cross linking system used allows a perfect moulding of the part free of Pinholes.

Sunsoar XLHI-1006 is SGS and FDA approved.

Packing & Delivery

Standard Packaging(For More Info Please Request TDS&MSDS.)

Our Company

Our Factory

Our Office

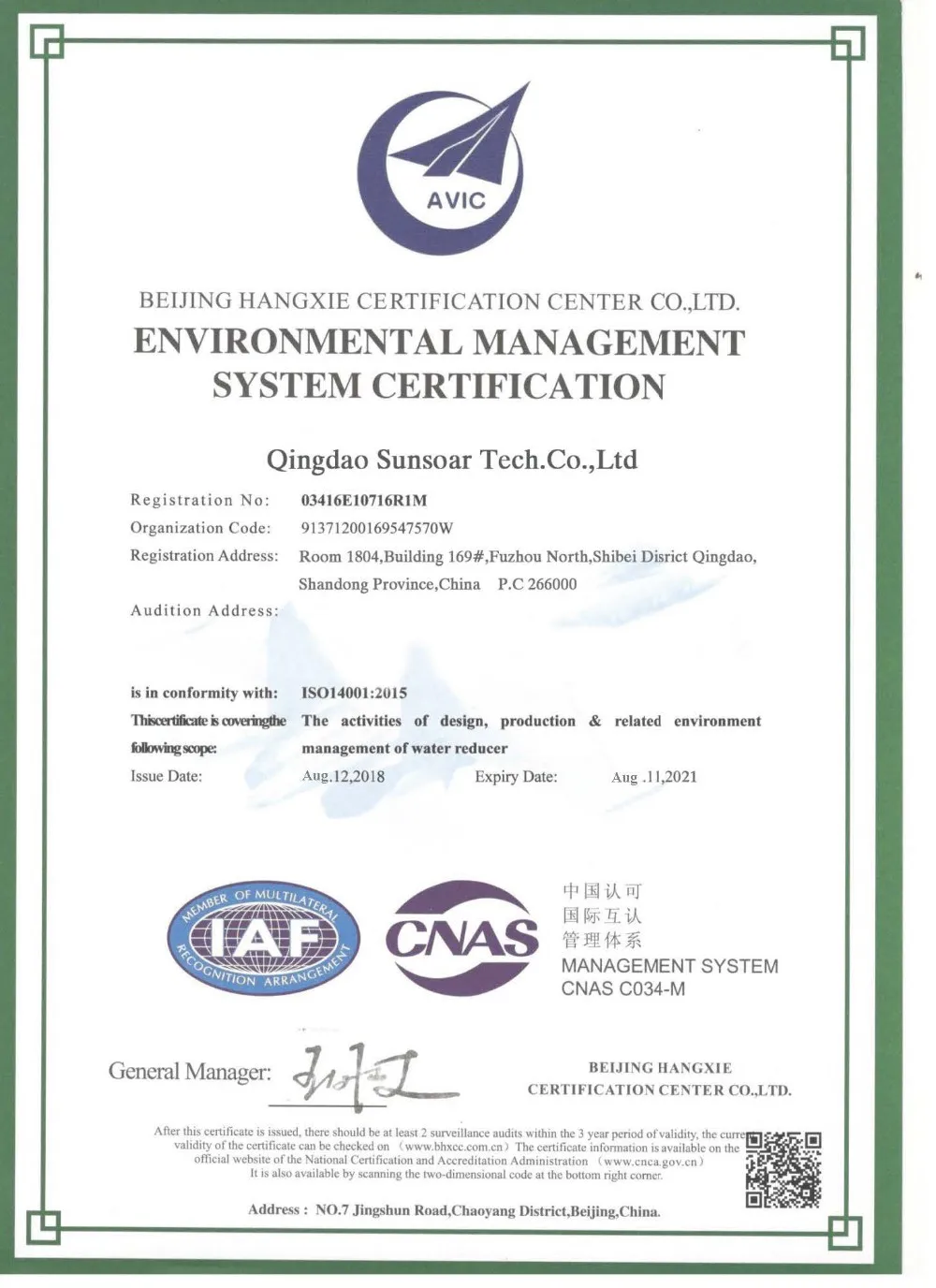

Certifications

Our Service

FOR MORE INFO ABOUT PRODUCTION PLEASE EMAIL US FOR PDS&MSDS.

FAQ002

CONTACT SUNSOAR

TEL:+86-532-889-84910

MOBILE:+86-180-532-33598

EMAIL: SUNSOAR at SUNSOARTECH.CN

WECHAT: 18053233598

VIEW MORE

You may like

-

Factory high price water tank making machine, septic tank making rotomolding machine

-

Rising Sun Kayak Rotomolder For Sale

-

High Quality Full Printed Plastic Ocean Kids PVC Ball Making Rubber Toys Molding Machine PVC Ball Making Machine

-

PE 500L 1000L 2000L Rotational plastic water tank machinery

-

Exporter Hot Sale Heavy Duty 4 Arms Dual Axis Rotational Molding Machine For Industrial Use

-

500 liters 1000 liters vertical water tank plastic making machine rock rotomolding machine

-

Cheapest water tank making machine Open flame machine rotary machine

-

High quality custom plastic boat rotational molding machine mold

-

Plastic thermoforming machine hollow parts rock plastic thermoforming machine

-

Balloon Making Products Machine Toy Making Rubber Soccer Small Printing Pvc Ball Making Machine